As a leading injection molding manufacturer, JS Precision is dedicated to providing high-quality solutions to meet the unique needs of our clients. One area of particular importance is heat-resistant ABS injection molding. This process requires careful attention to detail and specialized knowledge to ensure that the final product meets the required specifications. In this article, we’ll explore the key considerations for successful heat-resistant ABS injection molding.

- Material Selection

The first consideration for heat-resistant ABS injection molding is material selection. ABS is a thermoplastic polymer that is known for its strength and durability but can be prone to warping under high temperatures. To address this issue, heat-resistant ABS grades have been developed, which offer improved thermal stability and reduced shrinkage. When choosing a material for heat-resistant ABS injection molding, it’s important to consider the specific requirements of the application and select a material that can withstand the required temperature range. - Mold Design

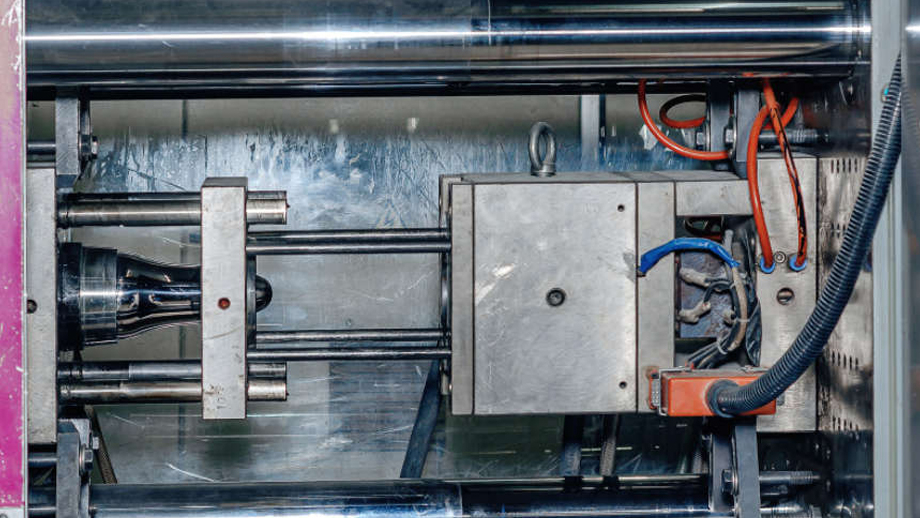

The design of the mold is another critical factor in heat-resistant ABS injection molding. The mold must be able to withstand the high temperatures involved in the process and maintain its shape and integrity. This requires careful consideration of factors such as mold material, cooling system design, and venting. The mold should be designed to allow for efficient cooling and minimize any areas of stress that could lead to warping or cracking of the final product. - Processing Parameters

The processing parameters used in heat-resistant ABS injection molding are also important to consider. This includes factors such as temperature, pressure, and injection speed. The specific parameters used will depend on the material being used and the requirements of the application. Specialized equipment may be needed to maintain the required temperature range and ensure consistent processing throughout the run. - Post-Molding Operations

After the injection molding process is complete, there are several post-molding operations that may be required to achieve the desired final product. This can include operations such as annealing, machining, and finishing. These operations must be carefully planned and executed to ensure that the final product meets the required specifications.

At JS Precision, we have extensive experience in heat-resistant ABS injection molding and can help you navigate the complexities of this process. Our team of experts can work with you to select the right material, design the mold, establish the optimal processing parameters, and execute the necessary post-molding operations. Whether you need a small prototype run or a large production run, we have the capabilities and expertise to meet your needs.

In conclusion, heat-resistant ABS injection molding requires careful attention to detail and specialized knowledge to ensure that the final product meets the required specifications. By considering the material selection, mold design, processing parameters, and post-molding operations, you can achieve successful results. At JS Precision, we are committed to providing high-quality solutions for all of your injection molding needs. Contact us today to learn more about our services and how we can help you achieve your goals.