As a professional 5-axis CNC manufacturer, JS Precision understands the importance of educating customers on the advanced capabilities of our machines. In this article, we will explore the functionality of 5-axis CNC machined parts and how they can benefit your manufacturing process.

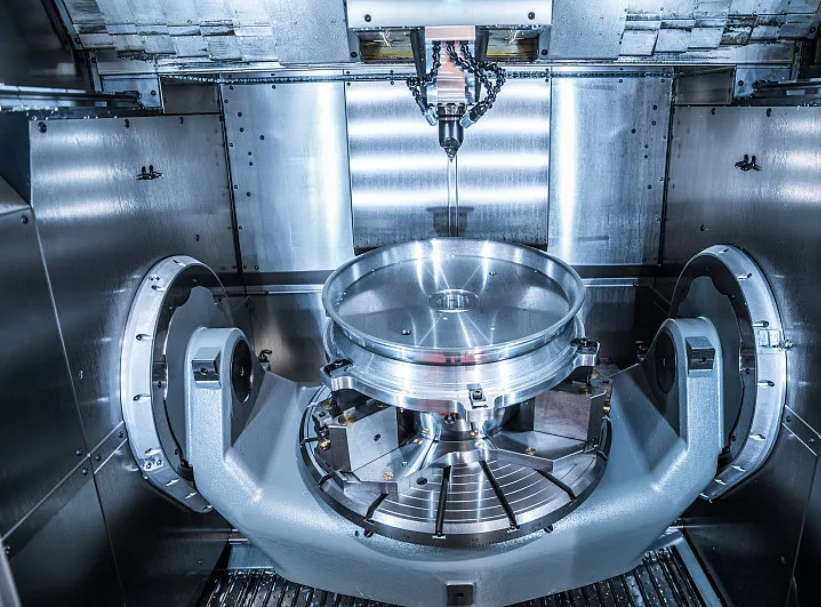

First, let’s define what a 5-axis CNC machine is. A 5-axis CNC machine is a computer-controlled machine tool that can move along five different axes simultaneously, allowing for intricate and complex shapes to be machined with precision. The five axes include X, Y, and Z (which control the movement of the machine along three axes) and A and B (which control the rotation of the cutting tool).

One of the main benefits of a 5-axis CNC machine is the ability to create complex shapes with a single setup. Traditional machining methods require multiple setups and adjustments to achieve the same results, which can be time-consuming and costly. With 5-axis CNC machines, parts can be machined in one operation, reducing lead times and costs.

Another benefit of 5-axis CNC machining is the ability to machine difficult-to-reach areas. The multi-axis design of the machine allows for the cutting tool to reach angles and contours that would be impossible with traditional machining methods. This opens up new possibilities for design and manufacturing, allowing for more intricate and complex parts to be machined.

5-axis CNC machines also offer improved accuracy and repeatability. The computer-controlled nature of the machine ensures that each part is machined exactly the same way, every time. This is especially important in industries such as aerospace and medicine, where precision and consistency are crucial.

In addition to these benefits, 5-axis CNC machines also offer increased efficiency and reduced waste. The ability to machine parts in one operation reduces the need for multiple setups and adjustments, which reduces the chances of errors and material waste. This ultimately results in a more streamlined manufacturing process and a higher quality end product.

When it comes to choosing a 5-axis CNC manufacturer, it’s important to consider factors such as experience, expertise, and quality. JS Precision has over 20 years of experience in the industry and a team of highly skilled engineers and technicians who are dedicated to delivering high-quality parts and exceptional customer service.

In summary, the functionality of 5-axis CNC machined parts offers numerous benefits to the manufacturing process, including increased efficiency, improved accuracy, and the ability to machine complex shapes with precision. As a professional 5-axis CNC manufacturer, JS Precision is committed to providing our customers with the highest quality parts and the latest in advanced machining technology. Contact us today to learn more about our services and how we can help take your manufacturing process to the next level.