Numerical control machining refers to the processing of CNC machining tools, which has developed into one of the most critical manufacturing processes used in workshops around the world. The development of CNC machining technology has spawned various forms and variations of the technology. These include 3-axis, 4-axis and 5-axis and 7-axis CNC machines.

As a leading supplier of CNC machining services, we regularly receive questions from our customers about how these technologies work. So, we decided to learn more about them through this article.

What Is 3-Axis CNC Machining ?

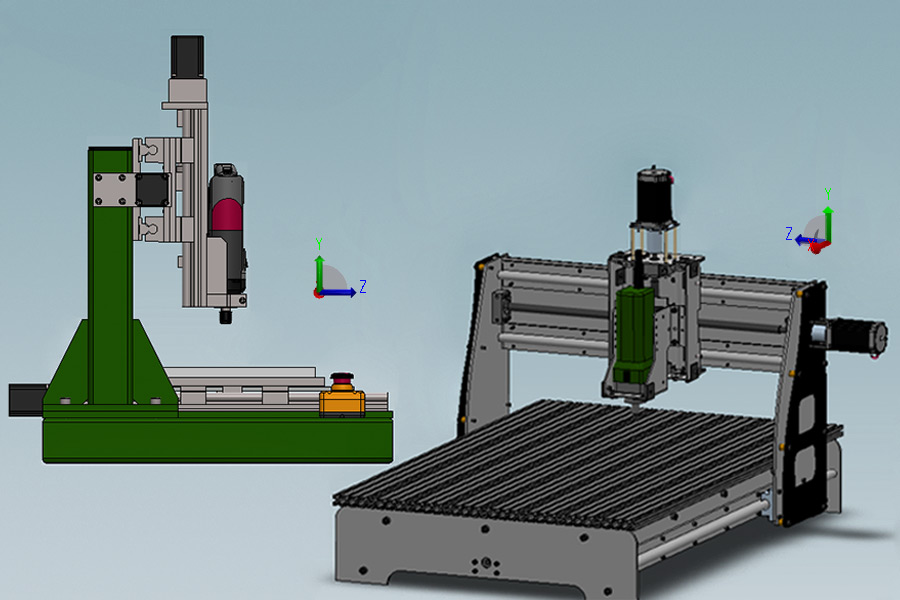

3-axis CNC machining has 3 axes that move in straight lines in different directions, namely X, Y and Z. The spindle of the CNC machining center moves in the X, Y and Z directions while the workpiece remains stationary. It can be used to create a variety of high-precision geometry, slot and face milling or drilling. The dimensional accuracy and repeatability of the machined parts are also very high.was expensive, programming was difficult, and labor costs skyrocketed

3 Axis, 4 Axis, 5 Axis and 7 Axis CNC Machining

Material Application、Advantages And limiting :

| Feature | 3-Axis CNC Machining | 4-Axis CNC Machining | 5-Axis CNC Machining | 7-Axis CNC Machining |

| Material Application | Wood, glass, metal and other building components | Wood, plastic, metal, composite, foam, ceramics | It is suitable for the processing of titanium alloy, stainless steel, aluminum alloy and other metal materials. | Plastics, composite materials, various metals and other materials |

| Advantages | Easy to program and operate, affordable, suitable for the production of large scale simple geometry parts | Capable of producing complex geometric parts | With higher repeatability and high precision, smooth surface finish | Higher precision and more complex parts can be produced, and the processing speed is faster |

| limiting | Making complex parts can be difficult | The cost is higher and can be difficult for very complex parts | The initial cost is high and programming is difficult, which means an increase in labor costs | Machinery was expensive, programming was difficult, and labor costs skyrocketed |

What is 4-axis CNC machining

4-Axis compared to 3-axis machines add an additional A-axis that rotates 360° around the X-axis, allowing the workpiece to rotate, adding additional degrees of freedom and improving precision and accuracy. In this way, the machine can be used as both a milling machine and a lathe. Allows complex parts to be machined and milled at any Angle, which is not possible with 3-axis machining.

What Is 5-Axis CNC Machining?

5-axis CNC machining adds two axes, usually A-axis and B-axis or C-axis, five axes can be fully processed to achieve a clamping, reduce clamping costs and product scratches, suitable for processing some parts with multi-station pores and parts with more strict shape processing accuracy requirements.

What Is 7-Axis CNC Machining?

By adding two additional rotating axes with greater flexibility and precision than five axes, complex parts can be machined from all angles, making it possible to produce complex shapes and geometry that were not possible before.

3 Axis, 4 Axis, 5 Axis and 7 Axis CNC Machining

Comparison:

| Relative Property | 3-Axis CNC Machining | 4-Axis CNC Machining | 5-Axis CNC Machining | 7-Axis CNC Machining |

| Price | lower | relatively high | high | very high |

| Parts Accuracy | lower | relatively high | high | very high |

| Part Complexity | Simple parts | More complex parts | Complex parts | Very complex parts |

| Surface Smoothness | not bad | good | very good | excellent |

Why is Longsheng the best choice for parts processing?

There are many reasons to choose our Longsheng CNC milling:

• High quality materials: Using only the highest quality materials and equipment, our manufacturing plant is equipped with advanced production lines that can handle a wide range of materials, including metals, plastics and composites.

• Strict tolerances: With more than 15 years of manufacturing experience, we handle cnc parts with tolerances up to 0.005mm.

• Lead time: We simplify the innovation cycle into four simple and effective steps. You can have flawless parts in just 3 days.

Working Principle And Application:![]()

Function | 3-Axis CNC Machining | 4-Axis CNC Machining | 5-Axis CNC Machining | 7-Axis CNC Machining |

| Move the machine in straight lines along the X, Y,and Z axes to create the desired shape | In addition to the three axes,an A-axis is added,rotating around the X-axis | It moves in the X, Y and Z directions and rotates in the two additional axes (A, B, C) | Add four additional rotation axes (A,B,C, and D) to the three linear axes to move arbitrarily |

Application Area | Ideal for simpler parts,flat surfaces | Suitable for more complex parts,rotary engraving | Ideal for complex and high-precision parts | More complex shapes and contours can be created |

Easiest to program and operate | More complex than triaxial and requires more advanced skills | It’s complicated and requires highly skilled operators | The most complex ones require extremely high skill on the part of the operator |

Conclusion

Three-axis machining is more accurate and cost-effective, suitable for simple parts processing, and has certain limitations for processing complex parts.4-axis milling adds A-axis, which, although more expensive than 3-axis machines, can process different faces of the workpiece and more complex parts.FAQs

Can a 5-Axis machine be used to complete a job that only requires 3-Axis machining?

Yes, the 5-axis machine can be used for 3-axis machining. However, it may not be cost-effective as 5-axis machines are generally more expensive to operate and maintain.

What is 5-Axis machining programming?

5-Axis machining programming is a kind of special programming methods and tools, usually using a special programming language or software when programming, through the linkage control of the 5-axes of the machine tool, to achieve accurate and efficient processing of complex curved parts, it is an indispensable technology in modern manufacturing.

How to find high-precision 3-Axis CNC machining service providers?

First, determine your specific needs. It is important to determine your specific requirements for a part or product before starting your search. Determine the material, tolerance and surface finish requirements of the part. Once you’ve identified your needs, you can start looking for a high precision 3-axis CNC machining service provider. Longsheng is your reliable choice. We focus on providing the highest quality CNC machining services to meet the needs of customers around the world.

Resource

What´s the difference between 3 Axis, 4 Axis & 5 Axis Milling?