Looking for a reliable injection molding company that offers high-quality products, fast delivery, and precision? Look no further than JS Precision Company! As a professional injection molding manufacturer, we understand the importance of choosing the right materials for injection molding. In this article, we’ll discuss the most commonly used injection molding materials in the industry.

- Acrylonitrile Butadiene Styrene (ABS)

ABS is a thermoplastic polymer that is commonly used in injection molding due to its high impact resistance, toughness, and heat resistance. It is a popular choice for products such as automotive parts, toys, and electronic housings. - Polypropylene (PP)

PP is a versatile thermoplastic that is known for its excellent chemical resistance, low density, and high stiffness. It is commonly used in injection molding for products such as food containers, medical equipment, and automotive parts. - Polyethylene (PE)

PE is a lightweight thermoplastic that is known for its flexibility, toughness, and chemical resistance. It is commonly used in injection molding for products such as packaging materials, toys, and automotive parts. - Polycarbonate (PC)

PC is a thermoplastic that is known for its high impact resistance, optical clarity, and heat resistance. It is commonly used in injection molding for products such as safety glasses, medical equipment, and electronic housings. - Polyoxymethylene (POM)

POM, also known as acetal, is a thermoplastic that is known for its high stiffness, low friction, and excellent dimensional stability. It is commonly used in injection molding for products such as gears, bearings, and electrical components. - Nylon (PA)

Nylon is a thermoplastic that is known for its high strength, toughness, and chemical resistance. It is commonly used in injection molding for products such as automotive parts, electrical components, and sports equipment. - Polystyrene (PS)

PS is a thermoplastic that is known for its clarity, stiffness, and ease of processing. It is commonly used in injection molding for products such as food packaging, toys, and electronic housings.

At JS Precision Company, we have experience working with all of these materials and more. We understand the unique properties and characteristics of each material, and we can help you choose the right material for your specific application. Whether you need a high-impact material for automotive parts or a chemical-resistant material for medical equipment, we have the expertise to meet your needs.

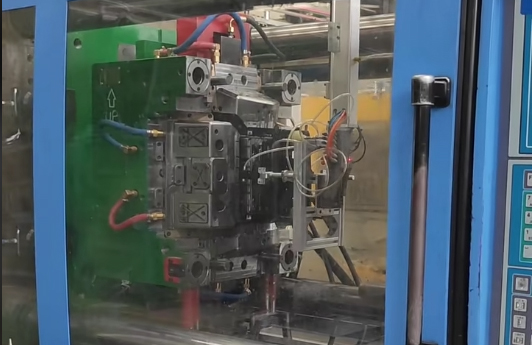

In addition to choosing the right material, it’s also important to ensure that the injection molding process is optimized for that material. At JS Precision Company, we use state-of-the-art equipment and techniques to ensure that our injection molding process is precise, efficient, and consistent. We also offer a range of secondary services, such as assembly and packaging, to provide a complete solution for our customers.

In conclusion, choosing the right material is essential for successful injection molding. At JS Precision Company, we have the experience, expertise, and equipment to help you choose the right material and optimize the injection molding process for your specific application. Contact us today to learn more about our injection molding services and how we can help you meet your product development goals.