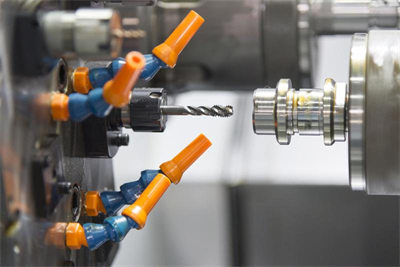

CNC (Computer Numerical Control) prototyping is a process that uses computer-controlled machines to produce physical prototypes of parts or products. CNC machines use software to control the movement of cutting tools, allowing for precise and accurate cuts that can create complex shapes and geometries. In this article, we will explore the benefits of CNC prototyping.

Precision

CNC machines can produce parts with extremely tight tolerances, ensuring that the physical prototype accurately represents the design. This precision is especially important in industries such as aerospace and medical device manufacturing, where accuracy is critical.

Speed

CNC machines can produce parts quickly, allowing for rapid iteration and design refinement. This speed is essential in industries such as automotive and consumer goods, where fast time-to-market is a competitive advantage.

Complexity

CNC machines can produce complex shapes and geometries that may be difficult or impossible to produce with traditional prototyping methods. This complexity is important in industries such as electronics and aerospace, where components need to be small and lightweight.

Material Selection

CNC machines can work with a wide range of materials, including metals, plastics, and composites, allowing for the selection of the most appropriate material for the prototype. This flexibility is important in industries such as automotive and consumer goods, where materials must meet specific requirements, such as strength or durability.

Cost-Effective

CNC prototyping can also be cost-effective in the long run, especially for high-volume production. While the initial investment in CNC machines can be high, the machines can produce parts quickly and consistently, reducing the need for manual labor. This can result in lower labor costs over time and higher productivity rates.

Reduced Waste

CNC prototyping is also a process that produces minimal waste. The precision of CNC machines ensures that material is used efficiently, reducing scrap material and waste. This not only reduces material costs but also contributes to a more sustainable manufacturing process.

Conclusion

In conclusion, CNC prototyping offers many benefits for product development and manufacturing. The precision, speed, complexity, material selection, cost-effectiveness, and reduced waste make CNC prototyping an ideal choice for many industries.