If you’re looking for a high-precision method of manufacturing complex parts, 5-axis CNC machining might be right for you. In this ultimate guide, we’ll cover everything you need to know about 5-axis CNC machining, from how it works to its advantages and applications. As a professional manufacturer, JS Precision is dedicated to providing customers with high-quality products and services, including 5-axis CNC machining.

What is 5-Axis CNC Machining?

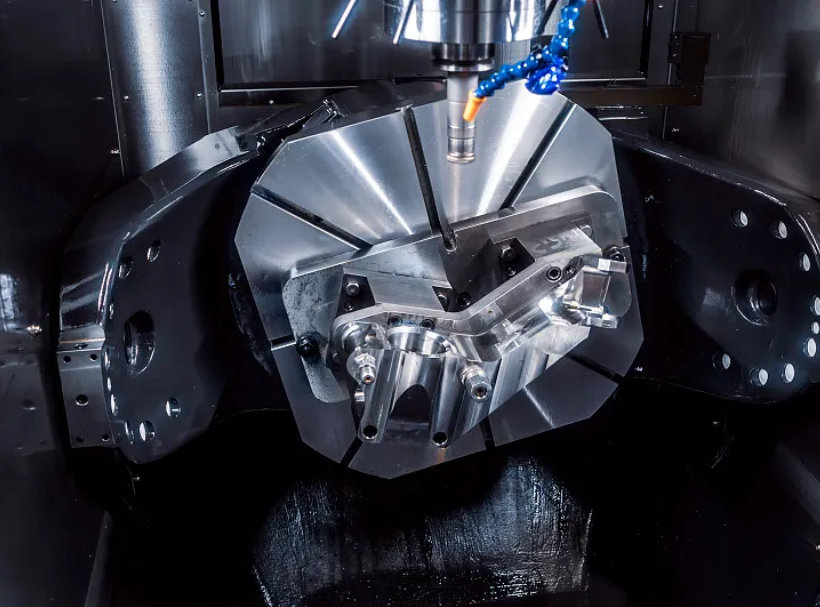

In traditional CNC machining, the cutting tool moves along three linear axes to remove material from a workpiece. In 5-axis CNC machining, the cutting tool can move along an additional two rotary axes, allowing it to approach the workpiece from any direction. This enables the production of complex parts with tight tolerances and intricate shapes.

Advantages of 5-Axis CNC Machining

Compared to traditional CNC machining, 5-axis CNC machining offers several advantages, including increased precision, reduced setup time, and the ability to produce complex geometries. Additionally, because the cutting tool can approach the workpiece from any angle, it can maintain a more consistent cutting speed and produce a better surface finish.

Applications of 5-Axis CNC Machining

5-axis CNC machining is widely used in a variety of industries, including aerospace, automotive, medical, and defense. It is particularly useful for producing complex parts with tight tolerances, such as impellers, turbine blades, and medical implants.

How to Choose a 5-Axis CNC Machining Provider

When choosing a 5-axis CNC machining provider, it’s important to consider factors such as experience, equipment, and quality control measures. Look for a provider with a proven track record of success in your industry, as well as state-of-the-art equipment and rigorous quality control processes.

The 5-Axis CNC Machining Process

The 5-axis CNC machining process consists of several steps, including CAD design, CAM programming, setup, machining, and inspection. Each step is critical to ensuring the quality and accuracy of the final product.

5-Axis CNC Machining Tips and Tricks

To get the most out of 5-axis CNC machining, it’s important to follow best practices and avoid common mistakes. Some tips and tricks to keep in mind include selecting the right cutting tools, using the correct cutting parameters, and optimizing your CAM programming.

The Future of 5-Axis CNC Machining

As technology continues to advance, the future of 5-axis CNC machining looks bright. New materials, software, and hardware are making it easier than ever to produce complex parts with tight tolerances and intricate geometries.

JS Precision’s 5-Axis CNC Machining Services

At JS Precision, we are committed to providing our customers with the highest quality 5-axis CNC machining services. Our state-of-the-art equipment and experienced technicians allow us to produce complex parts with tight tolerances and intricate shapes. Contact us today to learn more about our 5-axis CNC machining services.

As a professional manufacturer, JS Precision is dedicated to providing customers with high-quality products and services. If you’re looking for a reliable provider of 5-axis CNC machining services, look no further than JS Precision. Contact us today to learn more.