JS Precision is a professional injection molding manufacturer that specializes in creating high-quality plastic products for businesses worldwide. We understand the importance of precision and efficiency in the manufacturing process, which is why we use the latest technology and techniques to create the best possible products for our clients. One of the questions we often receive from our clients is the difference between blow-molded trays and injection-molded trays. In this article, we will explore the main differences between these two types of trays and why you should choose JS Precision for your molding needs.

Blow Molded Trays

Blow molding is a manufacturing process that involves creating hollow plastic parts by inflating a heated plastic tube until it fills a mold cavity. Once the plastic has cooled and solidified, the mold is opened, and the part is ejected. Blow-molded trays are typically used for packaging and storage, and they can be made in a variety of shapes and sizes. One of the advantages of blow molding is that it can produce parts with complex shapes and thin walls. However, the process is slower than injection molding, and the parts are not as precise.

Injection Molded Trays

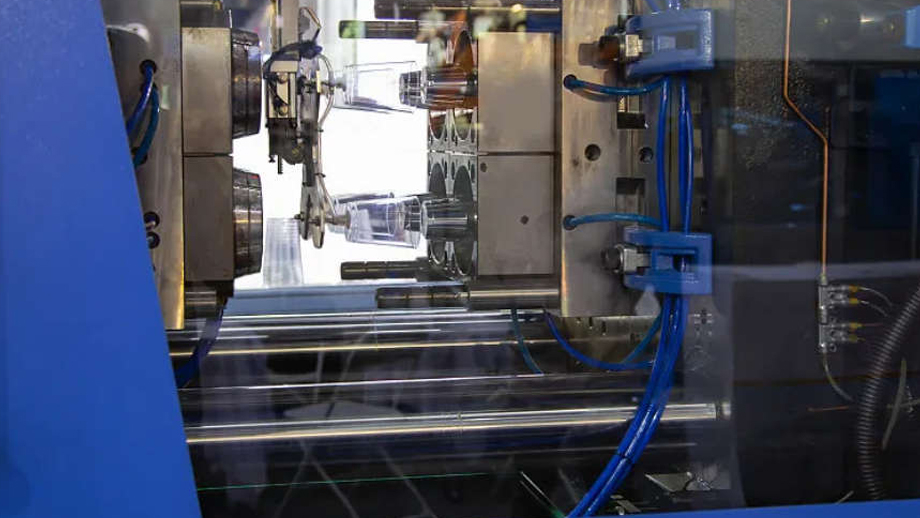

Injection molding is a manufacturing process that involves injecting molten plastic into a mold cavity. The plastic fills the cavity and then cools and solidifies, creating a solid plastic part. Injection molded trays are typically used for packaging, storage, and transportation, and they can be made in a variety of sizes and shapes. One of the advantages of injection molding is that it is a fast and efficient process that can produce parts with a high level of precision. Injection-molded parts are also stronger and more durable than blow-molded parts.

The Main Differences Between Blow Molded Trays and Injection Molded Trays

The main differences between blow-molded trays and injection-molded trays are the manufacturing process, the speed, and the precision. Blow-molded trays are created by inflating a heated plastic tube until it fills a mold cavity, while injection-molded trays are created by injecting molten plastic into a mold cavity. Injection molding is a faster and more efficient process than blow molding, and it can produce parts with a higher level of precision. Injection-molded parts are also stronger and more durable than blow-molded parts.

Why Choose JS Precision for Your Molding Needs?

JS Precision is the best choice for your molding needs because we specialize in injection molding, which is a faster and more efficient process than blow molding. We use the latest technology and techniques to create the best possible products for our clients, and we pride ourselves on our attention to detail and precision. Our team of experts has the experience and expertise to handle any project, no matter how complex or challenging. When you choose JS Precision for your molding needs, you can rest assured that you are getting the best possible products and services.

In conclusion, the main difference between blow-molded trays and injection-molded trays is the manufacturing process, speed, and precision. Injection molded trays are a faster, more efficient, and more precise option for packaging, storage, and transportation. If you need high-quality plastic products for your business, choose JS Precision. We specialize in injection molding and have the experience and expertise to handle any project. Contact us today to learn more about our services and how we can help you with your molding needs.