What is Mold Flow Analysis?

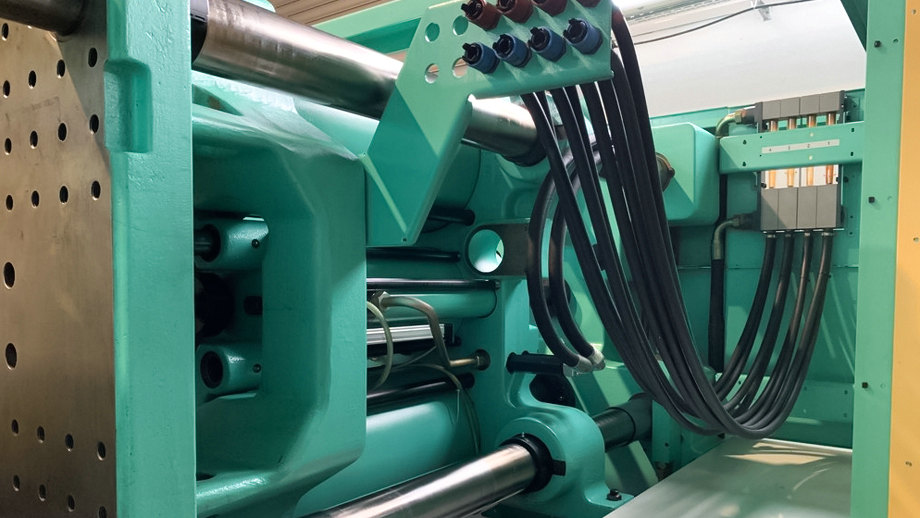

Mold flow analysis is a simulation tool used in the plastic injection molding process. It enables manufacturers to visualize and analyze the flow of plastics in a mold cavity during the injection molding process. This simulation helps manufacturers to predict and identify potential issues that may arise during the manufacturing process, such as sink marks, warpage, and air traps.

Why is Mold Flow Analysis Essential for Successful Production?

Mold flow analysis is crucial for successful production for several reasons:

- Ensures Quality Control

Mold flow analysis helps manufacturers to identify any potential issues before the manufacturing process begins. This enables manufacturers to make any necessary adjustments to the mold design or manufacturing process to ensure that the end product meets the required quality standards. - Reduces Manufacturing Costs

By identifying potential issues before production starts, manufacturers can make any necessary adjustments, reducing the need for costly rework or scrap. This optimization of the manufacturing process can save both time and money. - Increases Efficiency

Mold flow analysis enables manufacturers to optimize the manufacturing process by identifying the most efficient mold design and processing parameters. This optimization can help to reduce cycle time and improve overall efficiency. - Improves Product Performance

Mold flow analysis can help manufacturers to identify potential issues that may affect the product’s performance, such as warpage or sink marks. By making any necessary adjustments, manufacturers can improve the product’s performance and overall quality.

The Benefits of Choosing JS Precision for Your Mold Flow Analysis Needs

At JS Precision, we understand the importance of mold flow analysis in ensuring successful production processes. We offer the following benefits to our customers:

- Expertise

Our team of experts has years of experience in the plastic injection molding industry. We have the expertise to identify and resolve any potential issues that may arise during the manufacturing process. - Advanced Software

We use the latest mold flow analysis software, enabling us to provide accurate and detailed simulations of the manufacturing process. - Customized Solutions

We work closely with our customers to provide customized solutions tailored to their specific needs. Our team will work with you to identify any potential issues and provide solutions to ensure a successful manufacturing process. - Quality Assurance

At JS Precision, we are committed to providing our customers with the highest quality products and services. We ensure that all our mold flow analysis simulations are accurate and reliable, enabling our customers to make informed decisions about their manufacturing processes.

Conclusion

In conclusion, mold flow analysis is essential for successful production processes. It enables manufacturers to identify and resolve potential issues before the manufacturing process begins, reducing costs, increasing efficiency, and improving product performance. At JS Precision, we provide our customers with the expertise, customized solutions, and quality assurance needed for successful mold flow analysis. Contact us today to learn more about our services.