Injection molding is a widely used manufacturing process in the production of plastic parts. As a professional manufacturer, JS Precision understands that temperature plays a crucial role in ensuring consistent and high-quality parts. In this article, we will delve into the impact of temperature on injection molding and how it affects the final product.

What is Injection Molding?

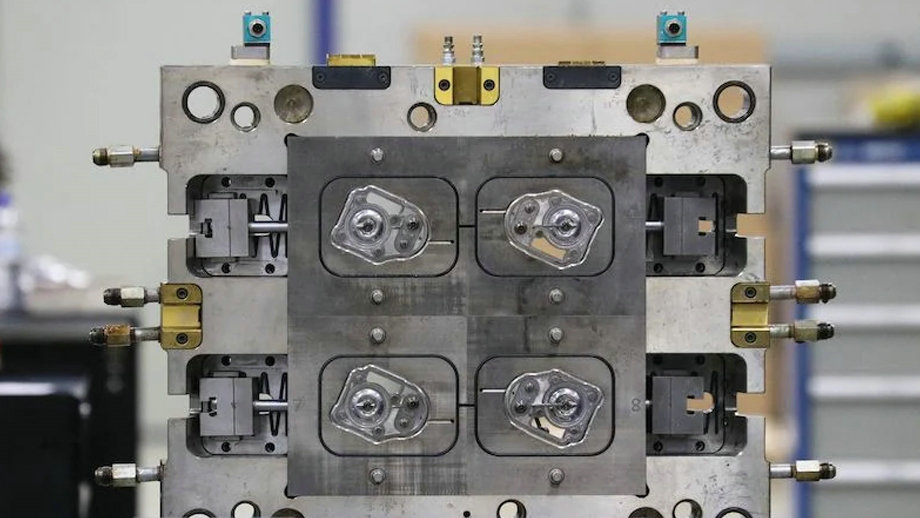

Before we explore the impact of temperature on injection molding, it’s essential to understand the process. Injection molding is a manufacturing process that involves injecting molten plastic into a mold cavity. Once the plastic cools and solidifies, the mold opens, and the part is ejected. The process can be repeated multiple times, producing identical parts that meet strict quality standards.

Why is Temperature Important in Injection Molding?

Temperature is a critical factor in injection molding as it affects the final product’s quality and consistency. Too low a temperature can cause the plastic to solidify before it reaches all parts of the mold cavity, resulting in incomplete parts. On the other hand, too high a temperature can cause the plastic to degrade and produce poor-quality parts. Maintaining the correct temperature is crucial to ensure consistent and high-quality parts.

What is the Optimal Temperature for Injection Molding?

The optimal temperature for injection molding varies depending on the plastic material being used. Each plastic material has a unique melting point, and the temperature should be set slightly above that point to ensure complete melting. Generally, the optimal temperature range for injection molding is between 200°C and 300°C.

How Does Temperature Affect the Molding Process?

The temperature affects various aspects of the injection molding process, including the flow rate, cooling rate, and shrinkage rate. Here are some of the critical ways temperature affects the molding process:

Flow Rate:

The flow rate of the plastic material increases with temperature. A higher temperature reduces the viscosity of the plastic, making it easier to flow into all parts of the mold cavity. However, if the temperature is too high, the plastic can flow too quickly, causing short shots or incomplete parts.

Cooling Rate:

The cooling rate of the plastic part also depends on the temperature. A higher temperature reduces the cooling rate, delaying the solidification of the plastic. A lower temperature increases the cooling rate, causing the plastic to solidify too quickly, resulting in incomplete parts.

Shrinkage Rate:

The shrinkage rate of the plastic part also depends on the temperature. A higher temperature reduces the shrinkage rate, resulting in a larger part. A lower temperature increases the shrinkage rate, resulting in a smaller part. It’s important to maintain the right temperature to ensure the correct size and shape of the final product.

What are the Common Temperature Control Methods in Injection Molding?

Temperature control is critical in injection molding to maintain the optimal temperature range. Here are some of the common temperature control methods used in injection molding:

Hot Runners:

Hot runners are a temperature control method where the plastic is kept molten in the runner system, ensuring consistent and accurate flow into the mold cavity.

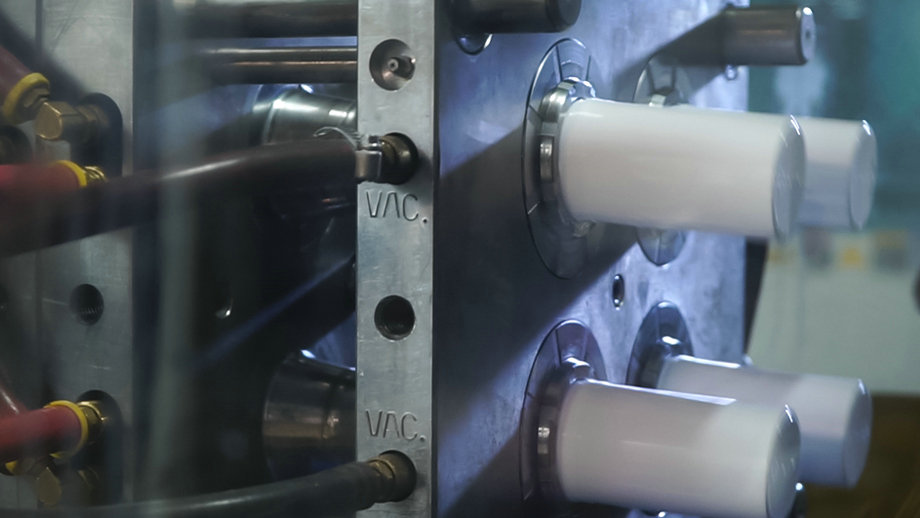

Cooling Channels:

Cooling channels are a temperature control method where cooling water is circulated through the mold cavity to maintain the optimal temperature range.

Heating Elements:

Heating elements are a temperature control method where the mold is heated to maintain the optimal temperature range. This method is commonly used in low-volume production runs.

How Does Temperature Affect the Quality of the Final Product?

Temperature affects the quality of the final product in various ways. Maintaining the optimal temperature range ensures consistent and high-quality parts. Here are some of the ways temperature affects the quality of the final product:

Surface Finish:

The surface finish of the final product is affected by the temperature. A higher temperature results in a smoother surface finish, while a lower temperature results in a rougher surface finish.

Color:

The temperature also affects the color of the final product. A higher temperature can cause discoloration or burning, resulting in poor-quality parts.

Strength:

The strength of the final product is also affected by the temperature. A higher temperature can cause the plastic to degrade, resulting in weaker parts.

Conclusion

Temperature plays a crucial role in injection molding, affecting the quality and consistency of the final product. As a professional manufacturer, JS Precision understands the importance of temperature control and maintains strict quality standards to ensure consistent and high-quality parts. By maintaining the optimal temperature range and using the right temperature control methods, we produce parts that meet our customers’ strict requirements.