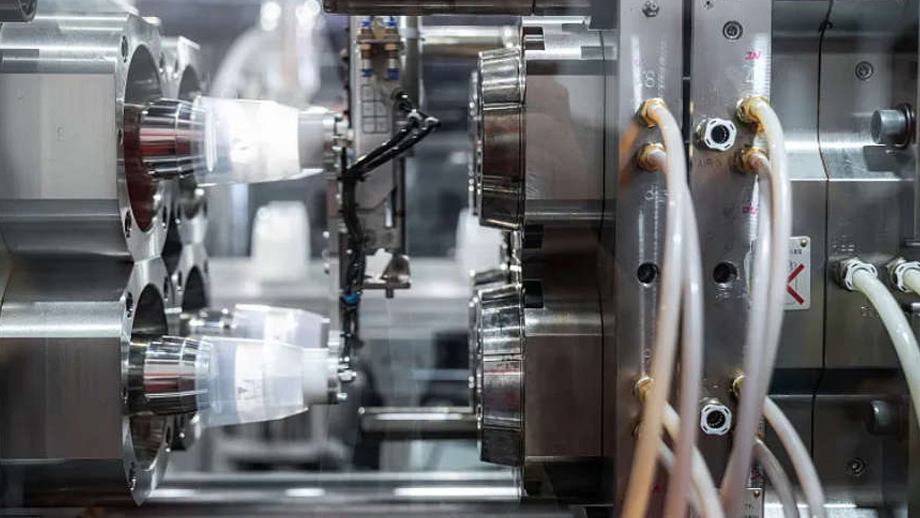

Welcome to JS Precision, the professional injection molding manufacturer that prioritizes quality and customer satisfaction. Our team of experts has years of experience in the industry, and we strive to deliver the best solutions to our clients. In this article, we will discuss the core of the injection molding process: control variable thinking.

Injection molding is a complex process that involves multiple variables. These variables include temperature, pressure, flow rate, cooling time, and more. Each variable plays a crucial role in the final product’s quality, and even a slight deviation from the optimum value can result in defects and inconsistencies. Therefore, it is essential to control these variables and maintain the ideal conditions throughout the process.

Control variable thinking is a systematic approach that focuses on identifying the critical variables and optimizing them for better results. It involves analyzing the process parameters, identifying the sources of variation, and implementing corrective measures to eliminate or reduce them. By using this approach, we can ensure that the injection molding process is consistent, repeatable, and reliable.

Let’s dive into the details of control variable thinking.

- Defining the Process

The first step in control variable thinking is to define the process. This includes identifying the inputs, outputs, and parameters that affect the process. It also involves establishing a clear and measurable goal for the process. Defining the process helps us understand the critical variables that need to be controlled and optimized.

- Identifying Critical Variables

The next step is to identify the critical variables that affect the process’s output. These variables may include temperature, pressure, flow rate, cooling time, and more. By analyzing the process data and conducting experiments, we can determine which variables have the most significant impact on the product’s quality.

- Optimizing the Variables

Once the critical variables are identified, we can start optimizing them. This involves setting the ideal values for each variable and ensuring that they are maintained throughout the process. We can use various tools and techniques to optimize the variables, such as the design of experiments (DOE), statistical process control (SPC), and more.

- Monitoring the Process

The final step is to monitor the process and ensure that the critical variables are controlled and optimized. We can use various monitoring tools, such as sensors, gauges, and software, to collect and process data and analyze it in real time. By monitoring the process, we can detect any deviations from the ideal conditions and take corrective measures immediately.

Conclusion

Control variable thinking is a crucial aspect of the injection molding process. By using this approach, we can ensure that the process is consistent, repeatable, and reliable. At JS Precision, we prioritize control variable thinking and use it to deliver high-quality products to our clients. If you have any inquiries or need assistance with your injection molding needs, please contact us today.