Introduction

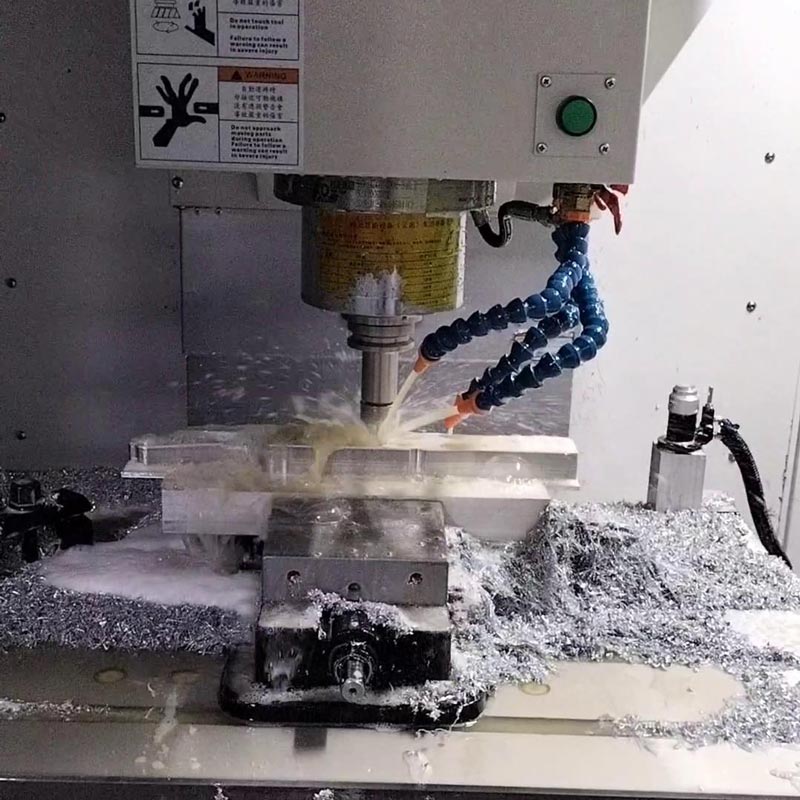

CNC machining has revolutionized the manufacturing industry with its high precision and accuracy. It is a computer-based technology that uses pre-programmed software to control a wide range of machinery tools. CNC machining has numerous benefits, and one of the most significant advantages is its long-term performance. In this blog post, we will explore the benefits of CNC machining for long-term performance.

High Precision and Accuracy

CNC machining provides high precision and accuracy in the manufacturing process. The computer-controlled technology ensures that the finished product meets the required specifications with minimal errors. This accuracy is maintained throughout the production process, ensuring that the finished product is of high quality.

The high precision and accuracy of CNC machining ensure that the product performs optimally, even after prolonged use. This is particularly important in industries such as aerospace, where precision is critical. CNC machining ensures that components such as aircraft engines, landing gear, and structural parts are produced to the highest standards, ensuring that they perform optimally throughout their lifespan.

Consistency

CNC machining provides consistency in the manufacturing process. The pre-programmed software ensures that every product is produced to the same specifications, regardless of the quantity or complexity of the product. This consistency ensures that the product performs consistently over time, even after prolonged use.

The consistent performance of CNC machined products is crucial in applications where precision and accuracy are paramount. Components such as medical implants, automotive engine parts, and industrial machinery rely on consistent performance to ensure safe and efficient operation. CNC machining ensures that these critical components are produced to the required standards, ensuring that they perform optimally throughout their lifespan.

Durability

CNC machined products are durable and can withstand prolonged use. The high precision and accuracy of CNC machining ensure that the finished product is of high quality, making it more durable. CNC machining also ensures that the product is produced to the required specifications, ensuring that it can withstand the intended use.

The durability of CNC machined products ensures that they perform optimally, even after prolonged use. This is particularly important in industries such as defense, where components such as tanks, missiles, and aircraft require exceptional durability. CNC machining ensures that these components are produced to the highest standards, ensuring optimal performance throughout their lifespan.

Cost-Effective

CNC machining is a cost-effective manufacturing process. The pre-programmed software ensures that the manufacturing process is efficient, reducing waste and minimizing the use of raw materials. The high precision and accuracy of CNC machining also reduce the need for rework, further reducing costs.

CNC machining is particularly cost-effective in industries where large quantities of components are required. The consistent performance and high-quality production ensure that the finished product is of high quality, reducing the need for maintenance and replacement. This, in turn, reduces costs, making CNC machining an excellent investment for manufacturers.

Conclusion

CNC machining provides numerous benefits for long-term performance. Its high precision and accuracy, consistency, durability, and cost-effectiveness ensure that the finished product performs optimally, even after prolonged use. CNC machining is an excellent investment for manufacturers, providing them with high-quality products that meet their customers’ requirements. By choosing CNC machining, manufacturers can ensure that their products perform optimally throughout their lifespan, providing customers with safe and reliable products.