Introduction

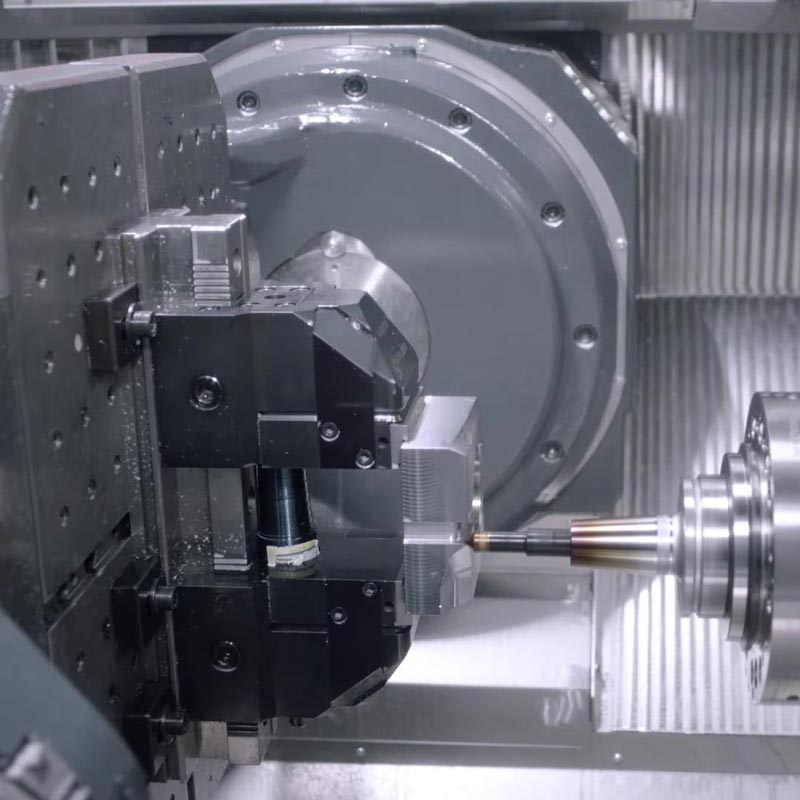

CNC (Computer Numerical Control) machines are used in manufacturing to automate the process of cutting, drilling, milling and other types of material removal from raw materials to create precise parts or components. With the advancement of technology, CNC machining has become a popular option for manufacturing high volume parts. It is a versatile and flexible manufacturing technology that can be customized to meet the specific needs of different industries such as aerospace, automotive, medical, and electronics. In this blog post, we will discuss the benefits of CNC machining for high production volumes.

Increased Efficiency

CNC machines are known for their efficiency and precision, which make them a perfect choice for high volume production. These machines can work continuously for long hours without stopping or slowing down, allowing for faster production times. CNC machines can also perform multiple tasks simultaneously, reducing the amount of time needed to produce each part. This increased efficiency leads to a reduction in production time, which can save companies money and improve their bottom line. Furthermore, CNC machines can be set up to run unattended, allowing operators to focus on other tasks, increasing production output with minimal supervision.

Consistency and Accuracy

One of the biggest benefits of CNC machining for high production volumes is the consistency and accuracy of the parts produced. CNC machines are programmed to create parts to exact specifications, ensuring that each part is identical to the others. This level of consistency and accuracy is almost impossible to achieve with manual machining methods, which can lead to errors and defects in the final product. By using CNC machines, companies can guarantee that their parts will meet the required specifications every time. CNC machines can also detect any variances in the material or machining process, enabling the operator to make necessary adjustments to ensure the production of high-quality parts.

Reduced Labor Costs

CNC machines require less human intervention than traditional machining methods, which means that fewer operators are needed to run them. This can result in a significant reduction in labor costs, which is especially important for companies with high production volumes. With CNC machines, companies can achieve a higher level of production with fewer employees, which can help to increase their profitability. Additionally, CNC machines reduce the risk of human error, which can result in costly mistakes and material waste.

Quality and Customization

CNC machines can work with a variety of materials, including metals, plastics, and composites, making them a versatile option for manufacturing different parts or components. CNC machining allows for customization of parts, which is particularly useful for producing parts with complex geometries or intricate designs. With CNC machines, companies can create parts with high precision, tight tolerances, and intricate details, ensuring that the final product meets the specifications and requirements of the customer.

Conclusion

CNC machining is an excellent option for companies looking to produce high volumes of parts with consistent quality and accuracy. The increased efficiency, consistency, and accuracy of CNC machines make them an attractive option for manufacturing companies looking to improve their bottom line. By reducing production time, ensuring consistent quality, and lowering labor costs, CNC machining is a cost-effective solution for high volume production. Furthermore, CNC machines can work with a variety of materials, enabling companies to customize parts to meet the specific needs of their customers. Overall, CNC machining is a reliable and versatile manufacturing technology that can help companies achieve their production goals and improve their profitability.