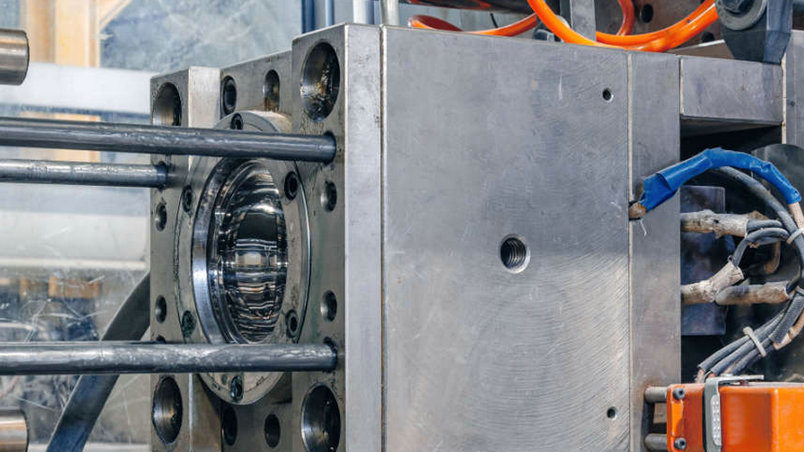

If you are in the manufacturing industry and looking for a way to produce high-quality plastic products, injection molding is one of the best processes you can use. Injection molding is a manufacturing process that involves injecting molten plastic material into a mold cavity. The material is then cooled and solidified, resulting in a final product that is identical to the mold cavity. However, to achieve a successful injection molding process, there are several factors that need to be considered. In this article, we will discuss ten factors that are critical when setting up the injection molding process.

- Material Selection

The type of plastic material used in injection molding can significantly affect the overall quality of the final product. You need to select the right material that can withstand the molding process and still maintain its properties. Factors that need to be considered when selecting the material include the strength, flexibility, temperature resistance, and durability of the material. - Mold Design

The mold design is essential to ensure that the final product is of high quality and meets your specifications. The mold design will determine the size, shape, and features of the final product. It is crucial to work with an expert to develop a mold design that meets your specifications. - Machine Selection

The size and type of injection molding machine used to produce the plastic product will affect the quality and efficiency of the process. You need to choose the right machine that can handle the volume and type of plastic material used. - Temperature Control

Temperature control is a critical factor in injection molding. The mold cavity and plastic material must be heated to the correct temperature to ensure that the final product is of high quality and consistent. You need to monitor and control the temperature throughout the process to avoid defects. - Injection Speed

The injection speed affects the overall quality of the final product. If the injection speed is too slow, the material will not fill the mold cavity properly, resulting in defects. If the speed is too fast, it can cause part deformation and other defects. - Cooling Time

The cooling time is the time it takes for the plastic material to cool and solidify after it has been injected into the mold cavity. The cooling time affects the cycle time and the quality of the final product. You need to ensure that the cooling time is long enough to avoid defects but short enough to maintain production efficiency. - Pressure

The pressure used during the injection molding process affects the flow of the plastic material and the quality of the final product. You need to ensure that the pressure is consistent throughout the process to avoid defects. - Venting

Venting is the process of allowing air to escape from the mold cavity during the injection molding process. Proper venting is critical to avoid defects such as voids and burns. You need to ensure that the mold design includes adequate venting to avoid these defects. - Wall Thickness

The wall thickness of the plastic product affects its strength, weight, and durability. You need to ensure that the wall thickness is consistent throughout the product to avoid defects such as warping and sink marks. - Ejector Pins

Ejector pins are used to eject the final product from the mold cavity. Proper ejector pin placement and design are critical to avoid defects such as part deformation and damage.

In conclusion, the injection molding process is complex, and several factors need to be considered to ensure that the final product is of high quality and meets your specifications. The ten factors discussed in this article are critical when setting up the injection molding process. If you are looking for a reliable injection molding service provider, JS Precision is the right choice. We have the expertise and experience to deliver high-quality plastic products that meet your requirements. Contact us today to learn more about our services and how we can help you with your injection molding needs.