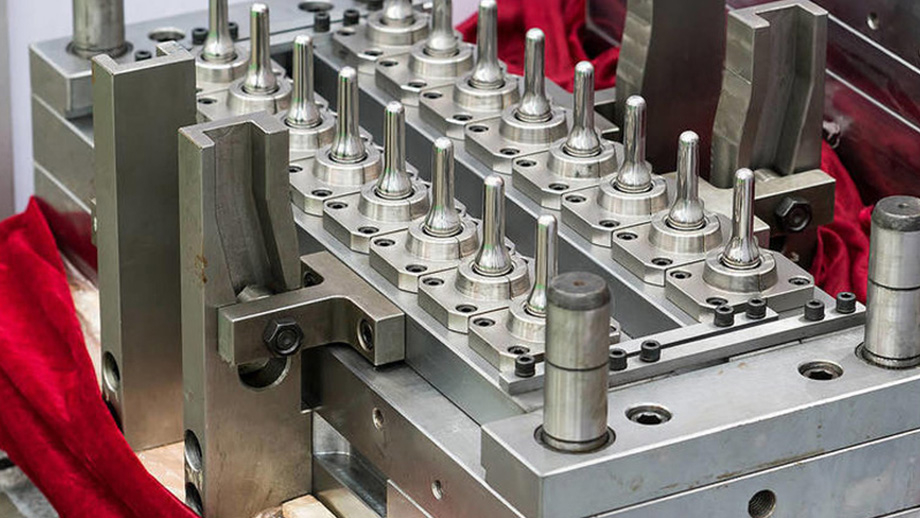

Are you looking to design metal inserts for injection molding products? If so, there are several points to consider. Metal inserts are commonly used in injection molding to add strength and durability to plastic parts. However, designing metal inserts requires careful consideration of material selection, design, and manufacturing processes. In this article, we will discuss some important points to keep in mind when designing metal inserts for injection molding products.

Material Selection

The first step in designing metal inserts is to select the appropriate material. The material should be chosen based on the specific application and environmental conditions. Some factors to consider when selecting a material include:

- Corrosion resistance: If the product will be exposed to corrosive environments, a corrosion-resistant material should be selected.

- Strength requirements: The material should be strong enough to withstand the forces applied to it during use.

- Thermal conductivity: If the product will be exposed to high temperatures, a material with high thermal conductivity should be selected.

- Cost: The cost of the material should be considered in relation to the overall cost of the product.

Some common materials used for metal inserts include stainless steel, brass, and aluminum. Each material has its own unique properties and advantages, so it is important to select the one that best fits the specific application.

Design Considerations

Once the material has been selected, the next step is to design the metal insert. There are several design considerations to keep in mind when designing metal inserts for injection molding products. These include:

- Wall thickness: The wall thickness of the metal insert should be thick enough to provide the necessary strength, but not so thick that it causes issues during the injection molding process.

- Draft angles: The design should incorporate draft angles to facilitate easy ejection of the part from the mold.

- Undercuts: Undercuts should be avoided in the design, as they can complicate the injection molding process.

- Surface finish: The surface finish of the metal insert should be smooth and free of any imperfections, as this can affect the quality of the final product.

It is important to work closely with the injection molding manufacturer during the design process to ensure that the design is optimized for the injection molding process.

Manufacturing Processes

Once the design has been finalized, the metal insert must be manufactured. There are several manufacturing processes that can be used to produce metal inserts, including:

- Machining: Machining involves using a cutting tool to remove material from a workpiece. This process is suitable for producing metal inserts with complex geometries or tight tolerances.

- Casting: Casting involves pouring molten metal into a mold to produce a part. This process is suitable for producing metal inserts with simple geometries.

- Powder metallurgy: Powder metallurgy involves compacting metal powder into a desired shape and then sintering it to produce a solid part. This process is suitable for producing metal inserts with complex geometries or high strength requirements.

The manufacturing process chosen will depend on the specific requirements of the metal insert and the quantity needed.

Conclusion

Designing metal inserts for injection molding products requires careful consideration of material selection, design, and manufacturing processes. By keeping these points in mind, you can ensure that your metal inserts are optimized for the injection molding process and will provide the necessary strength and durability for your product. If you have any questions about designing metal inserts, feel free to contact JS Precision for expert advice and assistance.