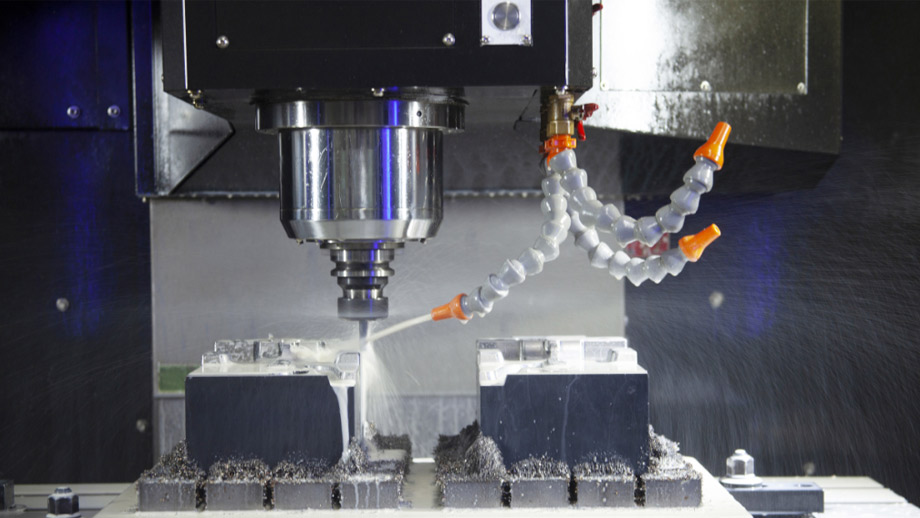

Medical CNC machining is a topic to watch in the making. CNC machining plays a very important role in the medical industry. CNC machining is an essential manufacturing process in the medical industry, where precision and accuracy are critical. CNC machining is a computer-controlled process that uses advanced software to produce high-quality parts with tight tolerances. In this article, we will explore the benefits of using CNC machining for medical parts, the types of medical parts that can be produced using CNC machining, and the challenges and considerations involved.

Benefits of Using CNC Machining for Medical Parts:

CNC machining offers several benefits for medical parts, including high precision and accuracy, consistency, and repeatability, and customization and flexibility. These benefits make CNC machining an ideal manufacturing method for a variety of medical parts, from implants and prosthetics to surgical instruments and diagnostic equipment.

High precision and accuracy are essential in medical parts, where even the smallest deviation can have significant consequences. CNC machining can produce parts with tight tolerances, ensuring the highest level of accuracy and precision. Consistency and repeatability are also crucial in medical manufacturing, where parts must be identical to ensure safety and efficacy. CNC machining can produce parts with consistent quality, reducing the risk of errors and ensuring the reliability of medical devices. Customization and flexibility are also essential in medical manufacturing, where each patient’s needs may vary. CNC machining can produce custom parts quickly and accurately, allowing manufacturers to meet the unique requirements of each patient.

Types of Medical Parts Produced using CNC Machining:

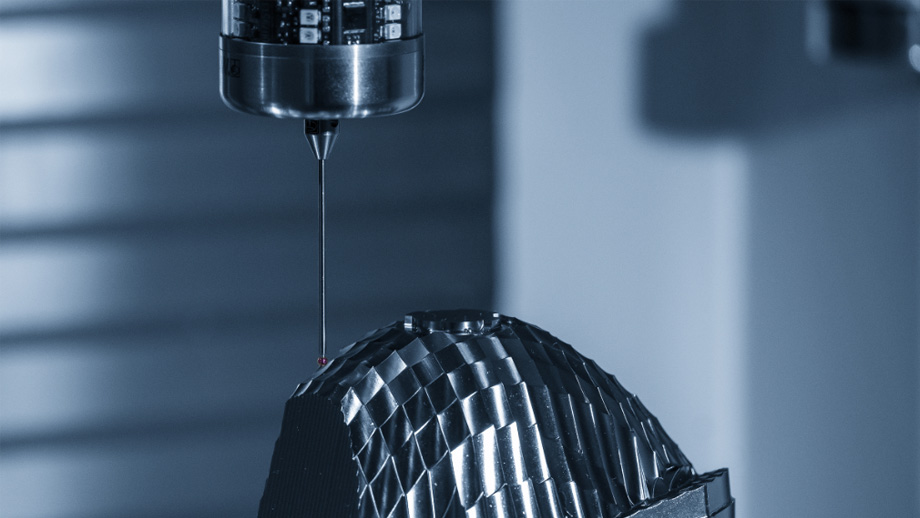

CNC machining can be used to produce a wide range of medical parts, including implants and prosthetics, surgical instruments, and diagnostic equipment. Implants and prosthetics require high precision and accuracy, as they must fit perfectly and integrate seamlessly with the patient’s body. CNC machining can produce implants and prosthetics with tight tolerances, ensuring a perfect fit and reducing the risk of complications. Surgical instruments also require high precision and accuracy, as even the slightest deviation can affect their performance. CNC machining can produce surgical instruments with consistent quality, ensuring their reliability and effectiveness. Diagnostic equipment requires precision and accuracy, as they must provide accurate measurements and readings. CNC machining can produce diagnostic equipment with high precision and accuracy, ensuring their reliability and accuracy.

Challenges and Considerations in Medical CNC Machining:

Medical CNC machining presents unique challenges, such as material selection and compatibility, sterilization and cleaning requirements, and regulatory compliance. Material selection and compatibility are critical in medical manufacturing, as the wrong material can cause adverse reactions or affect the performance of the device. CNC machining can work with a wide range of materials, including metals, plastics, and ceramics, allowing manufacturers to choose the best material for each application. Sterilization and cleaning requirements are also essential in medical manufacturing, as medical devices must be free of contaminants to ensure patient safety. CNC machining can produce parts with a smooth surface finish, reducing the risk of contamination and making them easier to clean. Regulatory compliance is also crucial in medical manufacturing, as medical devices must meet strict regulations and standards. CNC machining can produce parts with consistent quality, ensuring compliance with regulations and standards.

Conclusion:

CNC machining is an essential manufacturing method in the medical industry, where precision and accuracy are critical. By understanding the benefits and challenges of medical CNC machining, manufacturers can produce high-quality medical parts that meet the stringent requirements of the industry. CNC machining offers several benefits for medical parts, including high precision and accuracy, consistency, and repeatability, and customization and flexibility. CNC machining can produce a wide range of medical parts, including implants and prosthetics, surgical instruments, and diagnostic equipment. CNC machining in medicine presents unique challenges, such as material selection and compatibility, sterilization and cleaning requirements, and regulatory compliance. By addressing these challenges, manufacturers can produce high-quality medical parts that meet the highest standards of safety and efficacy. JS Precision is a professional CNC parts processing manufacturer. We can customize high-quality products for you on demand. If you have custom needs, you can upload your drawings to make your ideals a reality.