As a professional injection molding manufacturer, JS Precision understands the importance of a smooth and polished surface finish for plastic parts. However, sometimes matte surfaces can occur, which can be frustrating for manufacturers and customers alike. In this article, we will discuss the causes of matte surfaces and provide solutions to help you achieve the desired surface finish for your plastic parts.

Causes of Matte Surfaces

There are several reasons why matte surfaces can occur in plastic injection molded parts. Some common causes include:

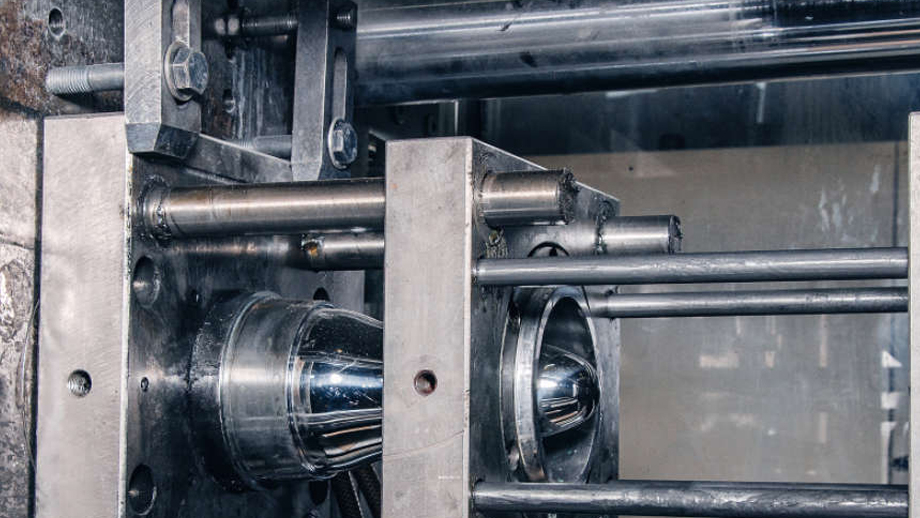

- Poor Mold Surface Finish: If the mold surface is not polished or textured properly, it can result in a matte surface finish on the part.

- Incorrect Material Selection: Certain materials are more prone to matte surfaces than others. Using the wrong material can result in a matte finish.

- Injection Molding Process: The injection molding process itself can also lead to matte surfaces if not done correctly.

Solutions to Matte Surfaces

- Improve Mold Surface Finish: One solution to matte surfaces is to improve the mold surface finish. This can be achieved by polishing the mold surface or adding texture to it. JS Precision uses state-of-the-art equipment and technology to ensure that our molds are of the highest quality and provide a smooth, polished surface finish.

- Material Selection: Choosing the right material is also important in achieving a smooth surface finish. JS Precision has a wide range of materials to choose from, and we can help you select the best material for your specific application.

- Injection Molding Process: Proper injection molding techniques are crucial in achieving a smooth surface finish. JS Precision has experienced technicians who are trained in the latest injection molding techniques to ensure that your parts are produced with the highest quality and surface finish.

Conclusion

In conclusion, matte surfaces can be frustrating for manufacturers and customers alike. However, with the right mold surface finish, material selection, and injection molding process, matte surfaces can be easily avoided. At JS Precision, we are committed to providing our customers with the highest quality plastic parts with a smooth and polished surface finish. Contact us today to learn more about our injection molding services and how we can help you achieve the perfect surface finish for your plastic parts.