introduction

Custom injection molding is a manufacturing process widely used in various fields. Its main advantages are the ability to produce large quantities of products in a short period of time and to achieve high-precision and high-complexity processing. However, at the same time, the cost of custom injection molding is relatively high, which requires us to master some skills to reduce the cost of custom injection molding.

Importance and Significance of Cost Reduction

Reducing costs is not only to save money but also to improve the competitiveness of enterprises. The cost reduction can make the product price of the enterprise more competitive, attract more customers, and then improve the market share and profitability of the enterprise.

Improvement of production efficiency

Productivity is one of the most critical factors in the custom injection molding process. Improving production efficiency can effectively reduce costs. In the production process, some time-saving techniques can be adopted, such as automated production lines, quick mold change systems, etc.

Three, material selection skills

Choosing the right material can reduce costs, increase production efficiency, and at the same time improve product quality. When choosing materials, factors such as material price, processing difficulty, strength, and durability should be considered to choose the most suitable material.

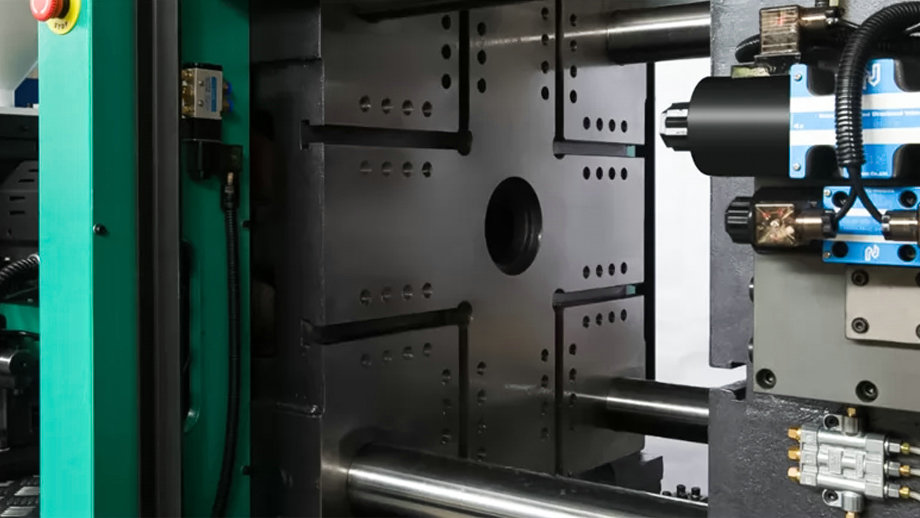

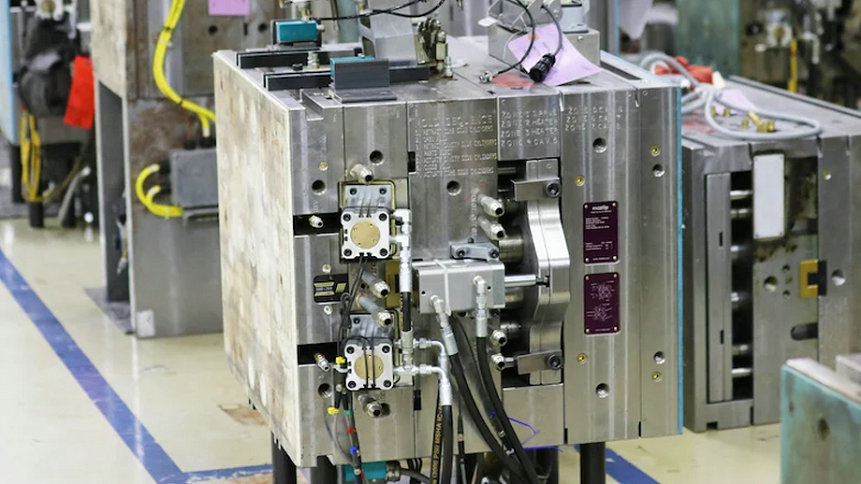

Optimization of mold design

Mold design is a very important part of the custom injection molding process. Optimizing mold design can reduce costs, increase production efficiency, and at the same time improve product accuracy and quality. In the mold design, factors such as the structure, size, material, and processing technology of the mold should be considered.

Process control of mold manufacturing

Mold making is an integral part of the custom injection molding process. Optimizing the mold manufacturing process can reduce costs, increase production efficiency, and at the same time improve product accuracy and quality. In mold manufacturing, factors such as mold material selection, processing technology, and manufacturing cycle should be considered.

The importance of process optimization

Process optimization is a very important part of the custom injection molding process. Through process optimization, costs can be reduced, production efficiency can be improved, and product quality can also be improved. In process optimization, factors such as the injection molding process, temperature control, pressure control, and flow rate control should be considered.

Methods and skills of equipment maintenance

Equipment maintenance is a very important part of the custom injection molding process. Regular equipment maintenance can prolong the service life of equipment, reduce maintenance costs, and improve production efficiency. In equipment maintenance, attention should be paid to the cleaning, lubrication, maintenance, and other aspects of the equipment.

Eight, the importance and methods of quality control

Quality control is a very important part of the custom injection molding process. Through quality control, costs can be reduced, production efficiency can be increased, and the quality of products can also be improved. In quality control, attention should be paid to product size, appearance, physical properties, etc., and appropriate testing methods should be used to ensure product quality.

Conclusion

Through the introduction of this article, I believe you have learned how to reduce the cost of custom injection molding without sacrificing quality. As a professional custom injection molding company, JS Precision has rich experience and advanced equipment and can provide you with comprehensive custom injection molding solutions. If you have any questions or needs, please feel free to contact us, we will serve you wholeheartedly.