Injection molding is a widely used manufacturing process that involves the creation of parts by injecting molten material into a mold. The quality of the mold used in the process is crucial to the success of the operation. In this article, we will discuss the steps required to make a mold for injection molding.

Step 1: Design the Part

The first step in creating a mold is to design the part that will be manufactured. This typically involves using computer-aided design (CAD) software to create a detailed 3D model of the part. The design should take into account the intended use of the part, as well as any requirements for strength, durability, and aesthetics. At JS Precision, we have a team of experienced engineers who use advanced software to design parts that meet our customers’ needs.

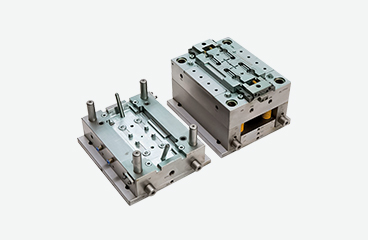

Step 2: Create a Mold Tool

Once the part has been designed, the next step is to create a mold tool. This involves using CNC machining equipment to create a negative impression of the part in a block of steel or aluminum. The mold tool is typically made up of two halves, known as the core and cavity, which fit together to create the final shape of the part. At JS Precision, we have state-of-the-art CNC machines that allow us to create complex molds with precision and accuracy.

Step 3: Injection Molding

With the mold tool complete, the next step is to use it in the injection molding process. This involves heating the material to its melting point and then injecting it into the mold under high pressure. The material then cools and solidifies, taking on the shape of the mold. At JS Precision, we use only high-quality materials and equipment to ensure that our injection molding process produces parts that meet our customers’ exact specifications.

Step 4: Finishing

Once the parts have been molded, they may require finishing to remove any excess material or improve their appearance. This can involve trimming, sanding, or polishing the parts as needed. At JS Precision, we have a team of skilled technicians who can provide a range of finishing services to ensure that our customers receive parts that meet their expectations.

Conclusion

Creating a mold for injection molding is a complex process that requires careful planning and attention to detail. At JS Precision, we have years of experience in the injection molding industry and can help you with all your manufacturing needs. Whether you need a simple mold for a small part or a complex mold for a large component, we have the expertise and equipment to get the job done right. Contact us today to learn more about how we can help you with your injection molding needs.