When it comes to prototyping machine components, there are several methods available. One of the most popular methods is to create a metal prototype using CNC machining. CNC machining is a subtractive manufacturing process that involves cutting away material from a block of raw material to create the desired shape. Here are the steps to make a metal prototype of a machine component using CNC machining:

Step 1: Design the Component

The first step in creating a metal prototype of a machine component is to design the component using CAD software. This will allow you to create a 3D model of the component that can be used for CNC machining. Make sure to include all the necessary details and specifications in the design.

Step 2: Choose the Material

The next step is to choose the material for the prototype. Common materials used for prototyping include aluminum, steel, and brass. The material you choose will depend on the requirements of the component and the manufacturing process.

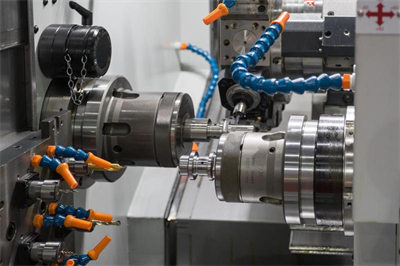

Step 3: Set Up the CNC Machine

Once you have the design and material, it’s time to set up the CNC machine. This involves selecting the appropriate cutting tools, setting the spindle speed, and adjusting the feed rate. The CNC machine will use the design file to cut away material from the block of raw material.

Step 4: CNC Machining

With the CNC machine set up, it’s time to start the machining process. The machine will cut away material from the block of raw material according to the design file. The cutting process may take several hours, depending on the complexity of the component.

Step 5: Finishing

Once the CNC machining is complete, the prototype will still need some finishing touches. This may include deburring, sanding, and polishing to remove any rough edges and give the component a smooth finish.

Step 6: Testing

The final step is to test the metal prototype of the machine component. This may involve checking for proper fit and function, as well as measuring the component to ensure it meets the necessary specifications.

Conclusion

In conclusion, creating a metal prototype of a machine component using CNC machining is a popular and effective method. By following these steps, you can produce a high-quality prototype that can be used for testing and validation. With the help of CNC machining, you can quickly produce precise and complex parts that meet your exact specifications.