If you are in the toy manufacturing industry, you know that PVC toys are among the most popular ones. However, producing high-quality toys is not a walk in the park. You need to ensure that the toys meet all the safety standards and are appealing to the target market. One of the critical aspects of producing PVC toys is controlling the injection temperature. In this article, we will discuss how to control the injection temperature in the production of injection PVC toys.

What is Injection Temperature?

Injection temperature is the temperature of the material when it gets injected into the mold. The injection temperature has a significant impact on the quality of the finished product. If the temperature is too low, the material will not flow correctly, leading to incomplete filling of the mold and low-quality products. Conversely, if the temperature is too high, the material will degrade, leading to poor surface finish and brittle products.

Factors Affecting Injection Temperature

Before we delve into how to control injection temperature, let us first look at the factors that affect it. Some of the factors include:

Material Type

Different materials have different processing temperatures. For instance, PVC has a lower processing temperature compared to other materials like ABS. Therefore, you need to adjust the injection temperature based on the type of material you are using.

Mold Material

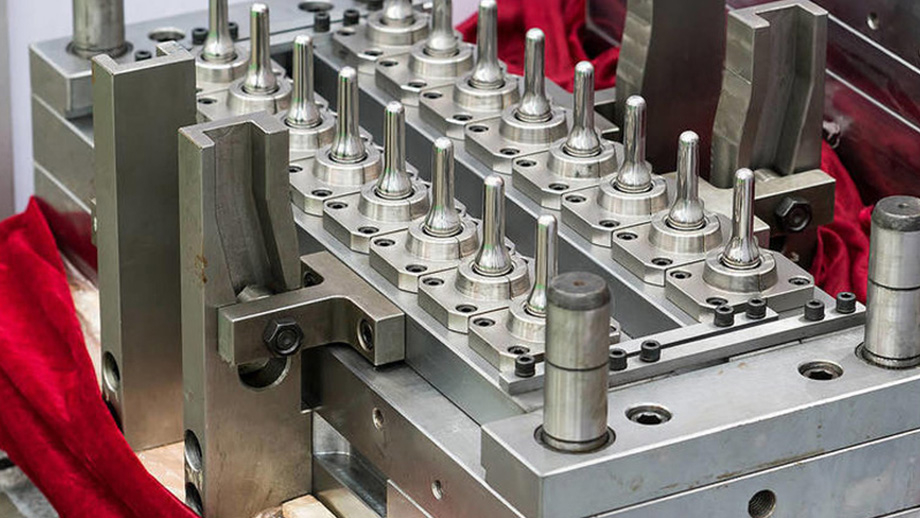

The mold material also affects the injection temperature. Different mold materials have different thermal conductivities. Therefore, you need to adjust the injection temperature based on the mold material to ensure the material fills the mold correctly.

Mold Design

The mold design also affects the injection temperature. The design will determine the flow path and the cooling time. Therefore, you need to adjust the injection temperature based on the mold design to ensure the material flows correctly and cools at the right time.

How to Control the Injection Temperature

Controlling the injection temperature is critical to producing high-quality PVC toys. Here are some tips to help you control the injection temperature:

- Monitor the Temperature

The first step to controlling the injection temperature is monitoring it. You need to ensure that the temperature is within the recommended range for the material you are using. The temperature should also be consistent throughout the injection process.

- Adjust the Injection Pressure

If the injection temperature is too low, you can increase the injection pressure to compensate for the low temperature. However, you need to be careful not to increase the pressure too much as it can lead to flash.

- Adjust the Cooling Time

If the injection temperature is too high, you can adjust the cooling time to compensate for the high temperature. However, you need to be careful not to reduce the cooling time too much as it can lead to warpage and deformation.

- Use a Mold Temperature Controller

A mold temperature controller can help you control the injection temperature more effectively. The controller will regulate the mold temperature, ensuring that it is within the recommended range for the material you are using.

- Work with a Professional Injection Molding Manufacturer

Working with a professional injection molding manufacturer like JS Precision can help you produce high-quality PVC toys. The manufacturer has the expertise and experience to control the injection temperature effectively, ensuring that you get high-quality products.

Conclusion

Producing high-quality PVC toys requires you to control the injection temperature effectively. You need to monitor the temperature, adjust the injection pressure, adjust the cooling time, use a mold temperature controller, and work with a professional injection molding manufacturer. By following these tips, you can produce high-quality PVC toys that meet all the safety standards and are appealing to the target market.