Introduction

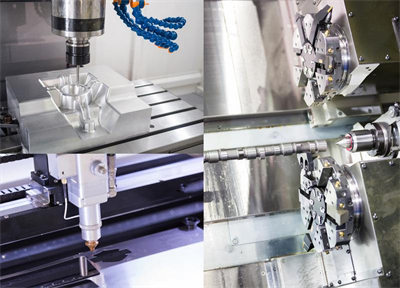

CNC turning is a manufacturing process that involves rotating a material on a lathe and cutting it to obtain a desired shape. Choosing the right CNC turning parts for your project is essential to ensure that you end up with a quality finished product. In this blog post, we’ll discuss three critical factors to consider when choosing the right CNC turning parts for your project.

Material

The material you choose for your CNC turning parts is the most important factor to consider. CNC turning machines can work with a wide range of materials, including metal, plastic, and wood. Each material has unique properties that can make it more or less suitable for a particular application. For example, if you’re creating a part that needs to be strong and durable, metal might be a better choice than plastic. However, if you’re creating a part that needs to be lightweight and corrosion-resistant, plastic might be a better choice than metal. When selecting the material for your CNC turning parts, you must consider factors such as strength, durability, and corrosion resistance. Choosing the right material will ensure that your parts function correctly and last longer.

Tolerance

Tolerance refers to the allowable deviation from a specified dimension or measurement. When it comes to CNC turning parts, tolerance is a critical factor to consider because it can affect the accuracy of your finished product. The tighter the tolerance, the more precise and accurate your parts will be. However, tighter tolerances can also increase the cost of your project. It’s important to consider your project’s requirements and budget when determining the appropriate tolerance for your CNC turning parts. Make sure to communicate your tolerances with your CNC machining service provider to ensure that they can deliver the required tolerance level, and the finished product meets your expectations.

Surface Finish

The surface finish of your CNC turning parts is another factor to consider. The surface finish can affect the appearance, functionality, and durability of your finished product. A smooth surface finish can enhance the appearance of your product and make it easier to clean. Additionally, a smooth surface finish can reduce friction and wear, which can improve the product’s functionality and longevity. When choosing your CNC turning parts, make sure to consider the required surface finish and choose a supplier that can provide the appropriate finish for your project. Communicate your surface finish requirements with your CNC machining service provider, as they can provide you with different surface finishes that meet your requirements.

Conclusion

Choosing the right CNC turning parts for your project is crucial to ensure you end up with a quality finished product. When selecting your CNC turning parts, make sure to consider the material, tolerance, and surface finish. By taking these factors into consideration, you can ensure your project is a success. It is also essential to communicate your requirements with your CNC machining service provider to ensure that they deliver the finished product that meets your expectations. With the right CNC turning parts, you can create high-quality products that meet your project’s requirements and exceed your customers’ expectations.