At JS Precision Company, we understand the importance of producing high-quality injection-molded products. Silver streaks are a common issue that can occur during the injection molding process. These streaks can negatively impact product quality and appearance, leading to customer dissatisfaction. In this article, we will provide tips on how to avoid silver streaks in injection molding.

What are Silver Streaks?

Silver streaks are shiny, silver-colored lines that appear on injection-molded products. These streaks are usually caused by the flow of molten plastic during the injection molding process. When the plastic flows too quickly or too slowly, it can cause silver streaks to appear on the surface of the product. These streaks are often a result of poor mold design or processing conditions.

How to Avoid Silver Streaks in Injection Molding

1、Optimize Mold Design

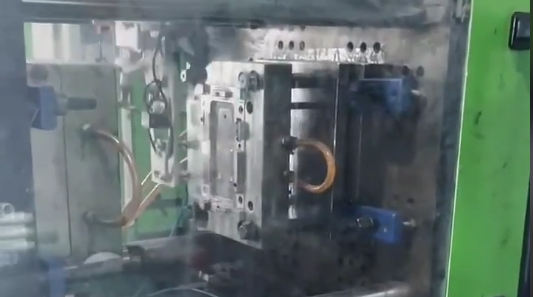

The first step in avoiding silver streaks is to optimize the mold design. The mold design should be based on the product’s shape and size, as well as the material being used. The mold should be designed with the proper gate size, runner system, and cooling system. A well-designed mold will ensure that the plastic flows evenly and smoothly, reducing the risk of silver streaks.

2、Control Processing Conditions

The processing conditions during injection molding can significantly impact product quality. The processing conditions include the temperature, pressure, and speed of the injection molding machine. These conditions should be carefully controlled to ensure that the plastic flows evenly and smoothly. Any changes in processing conditions can result in silver streaks or other defects in the product.

3、Use High-Quality Materials

The quality of the material used in injection molding can also impact product quality. Using high-quality materials can reduce the risk of silver streaks and other defects. The material should be chosen based on the product’s requirements, such as strength, durability, and appearance. Using the right material can ensure that the product is of high quality and meets customer expectations.

4、Maintain the Injection Molding Machine

Regular maintenance of the injection molding machine is essential to avoid silver streaks and other defects. The machine should be inspected and cleaned regularly to ensure that it is functioning properly. Any worn or damaged parts should be replaced immediately to prevent issues during the molding process. Proper maintenance can ensure that the machine is operating at peak performance and producing high-quality products.

5、Work with a Professional Injection Mold Manufacturer

Working with a professional injection mold manufacturer like JS Precision Company can help you avoid silver streaks and other defects. Our team of experts has years of experience in injection molding and can provide guidance on mold design, processing conditions, and material selection. We use state-of-the-art equipment and technology to produce high-quality products that meet customer expectations.

Conclusion

Silver streaks can negatively impact product quality and appearance, leading to customer dissatisfaction. By optimizing mold design, controlling processing conditions, using high-quality materials, maintaining the injection molding machine, and working with a professional injection mold manufacturer, you can avoid silver streaks and produce high-quality products. At JS Precision Company, we are committed to providing our customers with high-quality injection-molded products that meet their needs and exceed their expectations. Contact us today to learn more about our services.