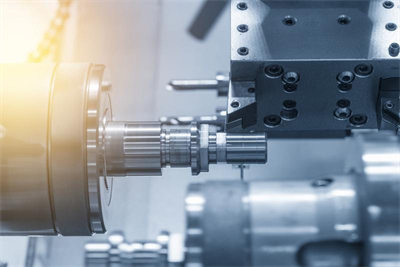

CNC machining is a process that uses computer-controlled machines to cut and shape materials into precise shapes and sizes. It is widely used in the manufacturing industry to produce high-quality parts with tight tolerances. However, producing good quality CNC machined parts requires careful planning, preparation, and execution. In this article, we will discuss some tips for producing good quality CNC machined parts.

Design for Manufacturability

Design for Manufacturability (DFM) is an essential part of producing good quality CNC machined parts. When designing a part, it is important to consider how it will be manufactured. This includes choosing the right materials, selecting appropriate tolerances, and minimizing complexity. By designing parts with manufacturability in mind, it is possible to produce high-quality parts that are easy to manufacture and assemble.

Choose the Right Materials

Choosing the right materials is critical to producing good quality CNC machined parts. Different materials have different properties, and it is important to select materials that are appropriate for the specific application. For example, some materials may be more prone to warping or distortion during machining, while others may be more difficult to machine. By selecting the right materials, it is possible to produce parts that meet the required specifications and are of high quality.

Use High-Quality Cutting Tools

Using high-quality cutting tools is another important factor in producing good quality CNC machined parts. Cutting tools that are dull or worn can produce parts with poor surface finish, dimensional accuracy, and tool life. By using high-quality cutting tools and maintaining them properly, it is possible to produce parts that are of high quality and meet the required specifications.

Optimize Machining Parameters

Optimizing machining parameters is critical to producing good quality CNC machined parts. Machining parameters, such as spindle speed, feed rate, and depth of cut, can have a significant impact on the quality of the parts produced. By optimizing these parameters, it is possible to produce parts that are of high quality and meet the required specifications.

Perform Quality Control

Performing quality control is essential to producing good quality CNC machined parts. Quality control involves inspecting parts to ensure that they meet the required specifications and are of high quality. This can include using measuring tools, such as micrometers and gauges, to check dimensional accuracy, surface finish, and other critical parameters. By performing quality control, it is possible to identify and correct any issues before the parts are delivered to the customer.

In conclusion, producing good quality CNC machined parts requires careful planning, preparation, and execution. By designing parts with manufacturability in mind, choosing the right materials, using high-quality cutting tools, optimizing machining parameters, and performing quality control, it is possible to produce parts that are of high quality and meet the required specifications.