Introduction: Understanding the Basics of CNC Machining

CNC machining is a manufacturing process that utilizes computer-controlled machines to produce complex and precise components. The process involves removing material from a workpiece using cutting tools that are guided by a computer program. CNC machining is essential for producing high-quality components with tight tolerances and complex geometries. In this article, we will explore the fundamentals of CNC machining and provide tips on how to produce good quality CNC machined parts.

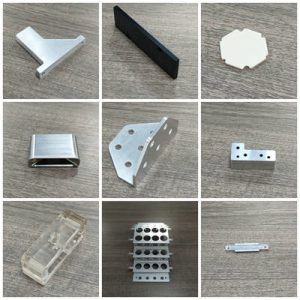

Materials Selection for CNC Machining

Choosing the right material for your CNC machined parts is critical to producing high-quality components. The most common materials used in CNC machining include metals such as aluminum, brass, steel, and titanium, as well as plastics such as ABS, polycarbonate, and nylon. Each material has unique properties that can affect the machining process, so it’s essential to select the right material for your specific application.

Designing for CNC Machining: Tips and Best Practices

Designing parts for CNC machining requires careful consideration of the part’s geometry and the machining process. To ensure that your parts are machined accurately and efficiently, it’s important to follow best practices such as limiting the number of setups, avoiding undercuts, and selecting appropriate tolerances.

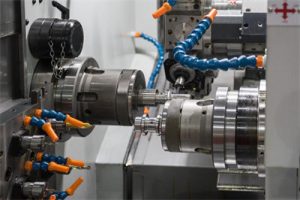

CNC Machining Processes: Milling, Drilling, Turning, and More

CNC machining encompasses a range of processes, including milling, drilling, turning, and more. Each process has unique advantages and limitations, so it’s important to select the right process for your specific application.

Tool Selection for CNC Machining

Choosing the right cutting tools is essential to producing high-quality CNC machined parts. Factors to consider when selecting cutting tools include material type, part geometry, and required surface finish.

CNC Machining Quality Control: Inspection and Testing Methods

Quality control is critical to ensuring that CNC machined parts meet the required specifications. Inspection and testing methods can include visual inspection, dimensional measurement, and material testing.

Troubleshooting Common CNC Machining Issues

Common issues that can occur during the CNC machining process include tool wear, chatter, and part distortion. Understanding and troubleshooting these issues is critical to producing high-quality CNC machined parts.

CNC Machining vs. 3D Printing: Which is the Better Option for Your Project?

Comparing CNC machining and 3D printing is essential to determining which process is better suited for your specific application. Factors to consider include material selection, part complexity, and required tolerances.

Conclusion: Tips for Producing High-Quality CNC Machined Parts.

In conclusion, producing high-quality CNC machined parts requires careful consideration of material selection, part design, machining processes, tool selection, quality control, and troubleshooting. By following best practices and selecting the right processes, you can produce high-quality CNC machined parts that meet your specific requirements.