Introduction

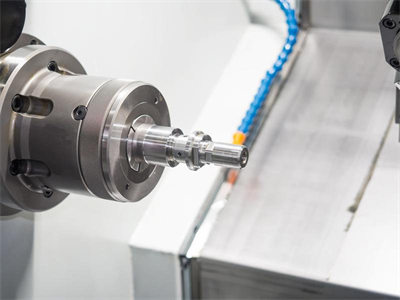

Manufacturing high-quality parts that meet customer specifications is crucial for businesses in the manufacturing industry. One popular method that can help achieve this goal is CNC turning. This process involves the use of computer-controlled machines that can produce precision parts with tight tolerances. In this blog post, we’ll explore in detail how CNC turning parts can help you achieve the highest quality results.

Increased Precision and Accuracy

One of the biggest advantages of using CNC turning parts is the increased precision and accuracy they offer. Traditional turning methods have a higher risk of human error, which can lead to imperfections in the final product. CNC turning machines, on the other hand, are programmed to produce parts with extremely tight tolerances, ensuring that each part is identical to the next. This level of precision is especially important for industries such as aerospace and medical, where even the smallest deviation can be catastrophic.

CNC turning machines use advanced software to control the cutting tools that shape and form the parts. The software can make adjustments to the machine’s settings in real-time, ensuring that the parts are produced with the exact specifications required. The machines can also produce complex shapes and designs with ease, further increasing precision and accuracy.

Faster Production Times

Another benefit of using CNC turning parts is the faster production times they offer. Traditional turning methods can be time-consuming since each part must be created manually. CNC turning machines, however, can produce parts at a much faster rate, allowing you to meet your production goals more efficiently. This increased speed also means that you can take on larger orders without sacrificing quality or delivery times.

CNC turning machines can also work continuously, allowing for 24/7 production without the need for breaks or rest periods. This can significantly increase production output and reduce lead times, giving your business a competitive edge in the market.

Cost-Effective Manufacturing

CNC turning parts can also be a cost-effective solution for your manufacturing needs. While there is an initial investment in the machines and software, the long-term benefits outweigh the costs. Traditional turning methods require skilled workers to operate the machines, which can be expensive. With CNC turning, you only need a small team to operate the machines and monitor the production process. This means you can save on labor costs and increase your profit margins.

CNC turning machines also produce less waste material since they are programmed to cut precisely without excess material. This reduces material costs and waste disposal fees, further increasing cost-effectiveness.

Conclusion

In conclusion, CNC turning parts offer numerous benefits that can help you achieve the highest quality results in your manufacturing process. With increased precision and accuracy, faster production times, and cost-effective manufacturing, it’s easy to see why CNC turning is such a popular method in the industry. By investing in CNC turning machines, you can take your manufacturing capabilities to the next level and stay ahead of the competition.