Have you ever seen a product with a glossy, polished surface and wondered how it was made? Chances are, it was created using high-gloss injection molding. This specialized process is used to produce parts with a smooth, reflective finish that looks as though it has been polished to perfection. In this article, we will explore the principles and requirements of high-gloss injection molding and the benefits it can offer to a wide range of industries.

What is High-Gloss Injection Molding?

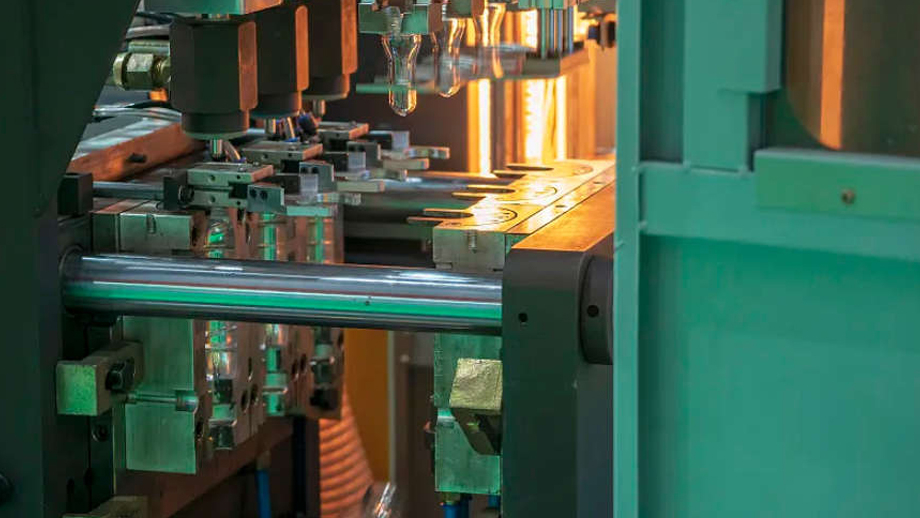

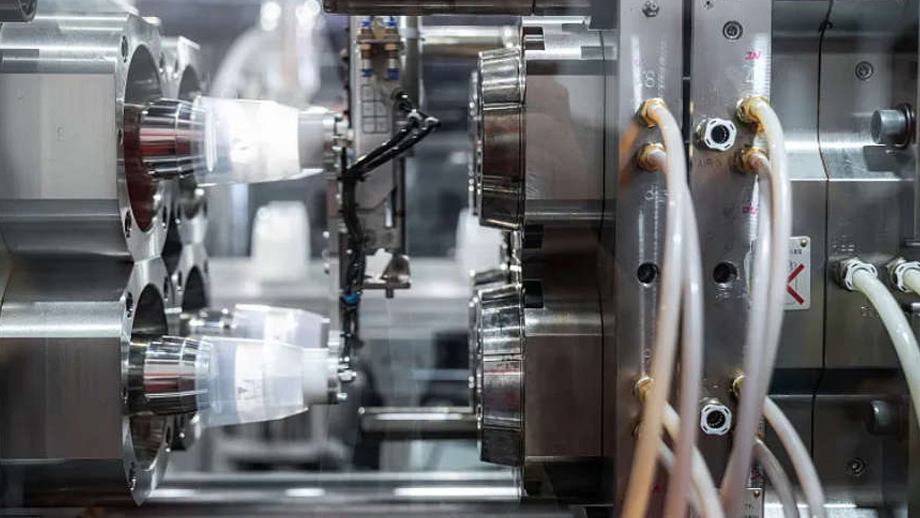

High-gloss injection molding is a process used to create parts with a smooth, polished surface finish. This process is ideal for creating parts that require a high-quality appearance, such as automotive interior parts, consumer electronics, and medical devices. The high-gloss finish is achieved by using a specialized tooling process, which creates a smooth surface texture on the finished product.

The Process Principles of High-Gloss Injection Molding

The process of high-gloss injection molding involves several stages. First, the mold is designed with a highly polished cavity and core. This is done to ensure that the surface of the finished product is as smooth as possible. Next, the plastic material is injected into the mold at a high pressure and temperature. The plastic is then allowed to cool and solidify, forming the finished product. Finally, the part is removed from the mold and polished to achieve the desired finish.

The Requirements of High-Gloss Injection Molding

In order to achieve a high-gloss finish, certain requirements must be met. First, the mold must be designed with a highly polished cavity and core. This is essential to ensure that the surface of the finished product is as smooth as possible. Second, the plastic material used must be of high quality. This means that it must be free from impurities and have a consistent viscosity. Finally, the injection molding machine must be capable of maintaining precise control over the temperature and pressure during the injection process.

The Benefits of High-Gloss Injection Molding

High-gloss injection molding offers a number of benefits to a wide range of industries. First, it allows for the creation of parts with a smooth, polished surface finish that looks as though it has been polished to perfection. This is essential for products that require a high-quality appearance, such as automotive interior parts, consumer electronics, and medical devices. Second, high-gloss injection molding is a highly efficient process that can produce parts quickly and cost-effectively. Finally, the process is highly customizable, which means that parts can be produced in a wide range of shapes and sizes.

Conclusion

High-gloss injection molding is a specialized process that offers a wide range of benefits to a variety of industries. By understanding the process principles and requirements of high-gloss injection molding, businesses can create parts with a smooth, polished surface finish that looks as though it has been polished to perfection. If you are looking for a high-quality injection molding manufacturer, JS Precision is an excellent choice. With years of experience and a commitment to quality, JS Precision can help you achieve the high-gloss finish you need for your products. Contact JS Precision today to learn more.