EVA injection molding is a technology widely used in the production of plastic products. It refers to the processing of ethylene vinyl acetate (EVA) materials through injection molding machines to make products of various shapes. Products generally have the characteristics of softness, durability, wear resistance, waterproof and UV protection. It has the advantages of high efficiency, precision, and stability, and is widely used in shoe materials, auto parts, household products, and other fields. Now, we will introduce its advantages, materials, common problems and solutions, and the reasons for choosing JS Precision.

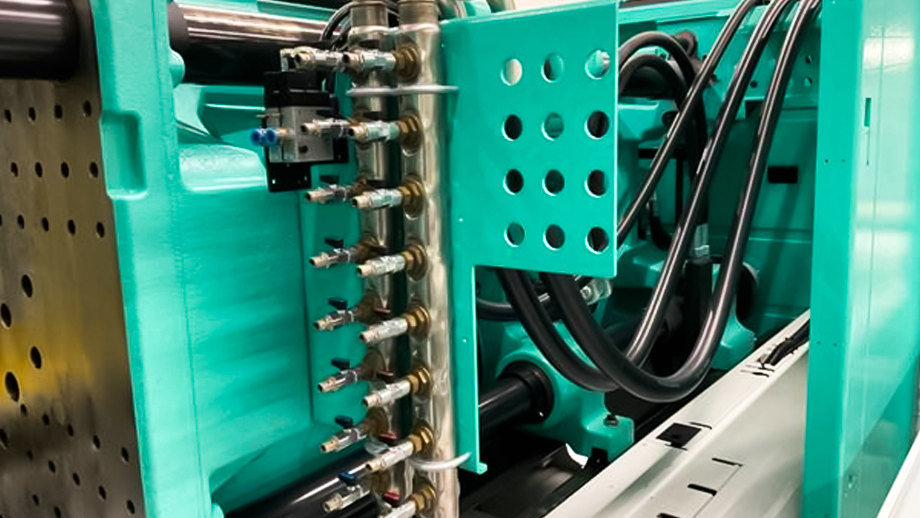

The production process of EVA injection molding is relatively simple. First, EVA particles are added to the hopper of the injection molding machine. After heating and melting, the molten EVA material is injected into the mold, and then controlled by pressure and temperature to make it cool and solidify, and finally get the desired product.

EVA injection molding technology has the following advantages:

- Efficiency: EVA injection molding technology can quickly manufacture a large number of products and improve production efficiency.

- Precision: EVA injection molding technology can produce high-precision products, which can meet various needs of customers.

- Stability: The production process of EVA injection molding technology is stable and reliable, which can guarantee the quality and consistency of products.

- Plasticity: EVA injection molding technology can produce products of various shapes and sizes, suitable for various fields.

EVA injection molding technology is widely used, mainly in the following fields:

- Shoe materials: EVA injection molding technology can produce various shoe materials, such as soles, insoles, etc.

- Auto parts: EVA injection molding technology can produce various auto parts, such as car mats, car mats, etc.

- Household items: EVA injection molding technology can produce various household items, such as floor mats, chair cushions, etc.

In short, EVA injection molding technology is an efficient, precise, and stable manufacturing technology, which is widely used in various fields. With the continuous advancement of science and technology, it will also continue to develop and innovate, providing better products and services for all walks of life.

Material

- Durability: The EVA material is very durable and can withstand long-term use and repeated use.

- Softness: EVA material is very soft and can adapt to various shapes and curves.

- Waterproof: EVA material has waterproof performance, which can prevent moisture from penetrating into the product.

- Wear resistance: EVA material has wear resistance and can withstand long-term wear and friction.

- Anti-ultraviolet: EVA material can prevent ultraviolet radiation, thereby protecting the surface of the product from damage.

Common problems and how to solve

- Sticking problem: During the EVA injection molding process, there may be sticking problems with plastic materials. This may be caused by insufficient temperature of the material or insufficient injection pressure.

Solution: You can increase the injection temperature or increase the injection pressure to solve this problem. In addition, additives can be used to improve the flow of the material, thereby reducing sticking problems.

- Air bubble problem: During the injection molding process, there may be air bubble problems. This may be due to insufficient fluidity of the material or excessive injection speed.

Solution: You can increase the injection pressure or slow down the injection speed to solve this problem. In addition, additives can be used to improve the flow of the material, thereby reducing air bubble problems.

- Material discoloration problem: During the injection molding process, there may be a problem of material discoloration. This may be caused by the temperature of the material being too high or the injection time being too long.

Solution: You can reduce the injection temperature or shorten the injection time to solve this problem. In addition, additives can be used to improve the heat resistance of the material, thereby reducing the problem of discoloration of the material.

- Mold wear problem: In the injection molding process, the mold may have wear problems due to long-term use. This may affect product quality and production efficiency.

Solution: You can regularly check the wear of the mold, and replace or repair the mold in time. In addition, high-quality molds can be used to extend the life of the mold.

Reasons to choose JS Precision

First of all, JS Precision has many years of experience and expertise to provide high-quality sheet metal products and services. Secondly, JS Precision has advanced equipment and technology, which can meet the different needs of customers. In addition, JS Precision focuses on customer needs and feedback and is able to provide personalized solutions and services. Most importantly, JS Precision is committed to quality and reliability, ensuring that each product meets international standards and customer expectations. These factors make JS Precision a reason for customers to trust and choose.

In addition, JS Precision also pays attention to environmental protection and sustainable development, using environmentally friendly materials and processes to reduce the impact on the environment. At the same time, JS Precision actively explores new technologies and materials and continuously improves the quality and performance of products to meet the changing needs of customers. In addition, JS Precision also provides competitive prices and timely delivery, so that customers can not only obtain high-quality products and services but also obtain more economic benefits when choosing JS Precision.

In addition, JS Precision focuses on cooperation and communication with customers to establish long-term cooperative relationships. JS Precision’s professional team can work closely with customers to understand their needs and requirements and provide the best solutions. JS Precision also provides a full range of after-sales services to ensure smooth and satisfactory customer use of the product. You can safely choose JS Precision as your EVA injection molding manufacturer because JS Precision is not only a supplier but also a trustworthy partner.