In this article, we will explore the numerous advantages of using hot runner systems in injection molding, and how they can significantly improve the efficiency and quality of your production process.

Introduction

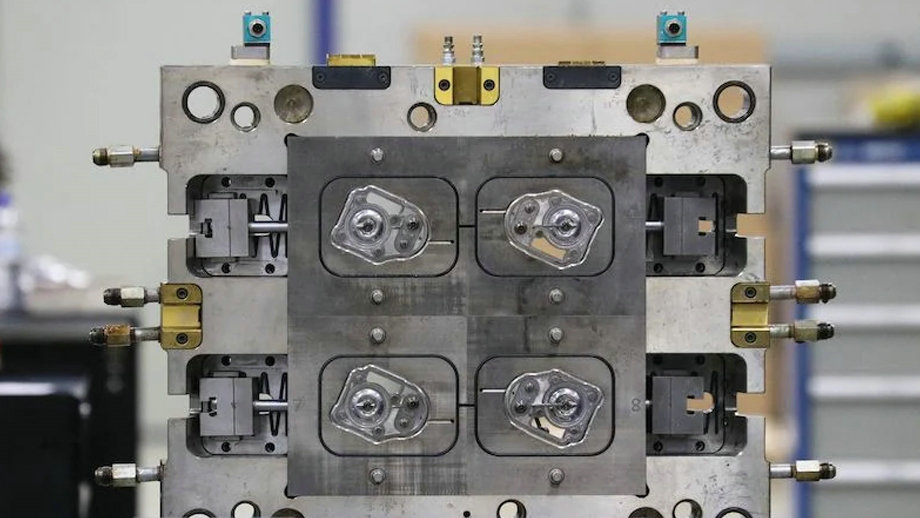

Injection molding is a widely used manufacturing process that involves injecting molten material into a mold to produce parts and components for various industries. Hot runner systems are an essential component of the injection molding process, as they help to deliver molten material to the mold with precision and accuracy. JS Precision is a professional manufacturer of hot runner systems, and we understand the importance of using these systems for high-quality and efficient production. In this article, we will discuss the benefits of using hot runner systems for injection molding.

Reduced Cycle Times

One of the primary advantages of using hot runner systems is that they can significantly reduce cycle times. This is because hot runner systems allow for the precise control of the temperature and flow of the molten material, which can help to improve the filling and cooling times of the mold. By reducing cycle times, you can increase the efficiency of your production process and reduce the time and cost associated with manufacturing.

Improved Quality

Another key benefit of using hot runner systems is that they can improve the quality of your parts and components. This is because hot runner systems can help to reduce the occurrence of defects, such as sink marks, warpage, and flash. By delivering molten material to the mold with precision and accuracy, hot runner systems can ensure that the parts and components produced are of high quality and meet the required specifications.

Reduced Material Waste

Hot runner systems can also help to reduce material waste, which is a significant concern in injection molding. This is because hot runner systems allow for precise control of the flow of molten material, which can help to minimize the amount of material that is wasted during the production process. By reducing material waste, you can save money and resources, and also reduce the environmental impact of your manufacturing operations.

Increased Flexibility

Hot runner systems can also increase the flexibility of your production process. This is because they can be customized to meet the specific requirements of your parts and components, and can also be adjusted to accommodate changes in design or production needs. By providing greater flexibility, hot runner systems can help to improve the efficiency and productivity of your manufacturing operations.

Enhanced Design Capabilities

Another advantage of using hot runner systems is that they can enhance the design capabilities of your products. This is because hot runner systems can help to achieve complex geometries and intricate details that may not be possible with other injection molding methods. By providing greater design capabilities, hot runner systems can help to differentiate your products from those of your competitors and provide a competitive advantage in the market.

Reduced Maintenance Costs

Hot runner systems can also help to reduce maintenance costs, which is a significant concern for many manufacturers. This is because hot runner systems are designed to be durable and reliable, and require minimal maintenance and repair. By reducing maintenance costs, you can save money and resources, and also reduce the downtime associated with maintenance and repair.

Increased Productivity

Finally, hot runner systems can increase the productivity of your manufacturing operations. This is because they can help to reduce the time and cost associated with manufacturing, and also improve the efficiency and quality of your production process. By increasing productivity, hot runner systems can help to increase the profitability and competitiveness of your business.

Conclusion

In conclusion, hot runner systems are an essential component of the injection molding process and can provide numerous benefits for manufacturers. From reducing cycle times and material waste to improving quality and design capabilities, hot runner systems can help to improve the efficiency and productivity of your manufacturing operations. If you are interested in learning more about hot runner systems, please contact JS Precision, a professional manufacturer of hot runner systems with years of experience and expertise in the industry.