In sheet metal fabrication, the hemming process includes bending the identical part’s sharp edges to form a reinforcement channel. This process is broadly used throughout the automotive and electronics industries. It cuts skinny sheet metal and makes the perimeters flat to create a inflexible construction from the fabric. The sides will be sewn too near form a closed finish or left partially open to create an open finish. Therefore, the primary objective of customized sheet metal hemming is two-fold. Firstly, it contributes to growing the general stiffness of the construction and excluding the chance of cracks and warping on the edges. Second, it will increase the aesthetic look of the metal for the reason that edges aren’t sharp, and the surface is smoother and simpler to shine. The hemming process is handiest when used on skinny sheets of metals, and the gauges are normally no more than 0. 125 inches.

Thicker sheets aren’t very best for hemming as they’re extra vulnerable to cracking when bent in the course of the process. This text is in regards to the sheet metal fundamentals, particularly sheet metal hemming, its varieties, strategies, functions, and its advantages in sheet metal fabrication.

Methods For Sheet Metal Hemming

There are two strategies generally used for hemming metal parts. These embrace;

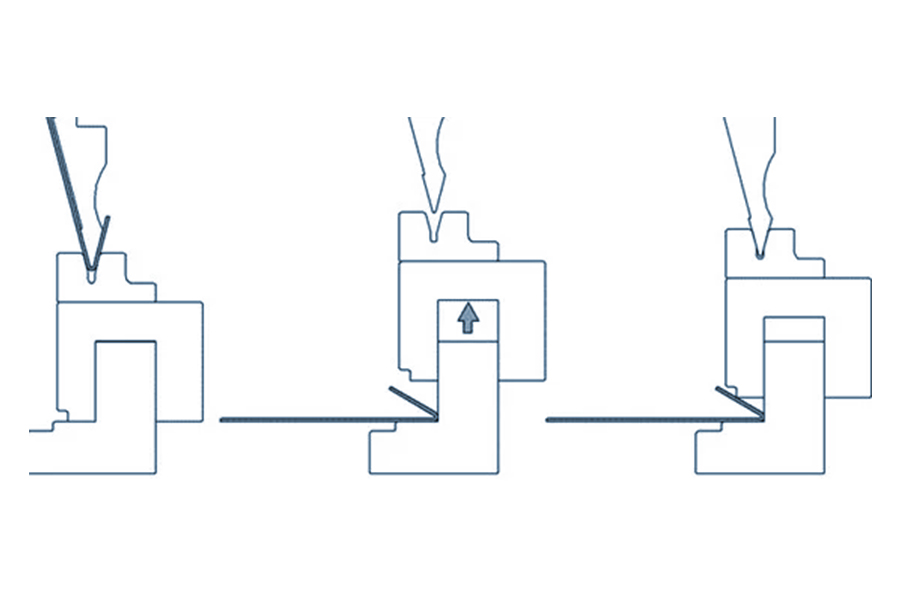

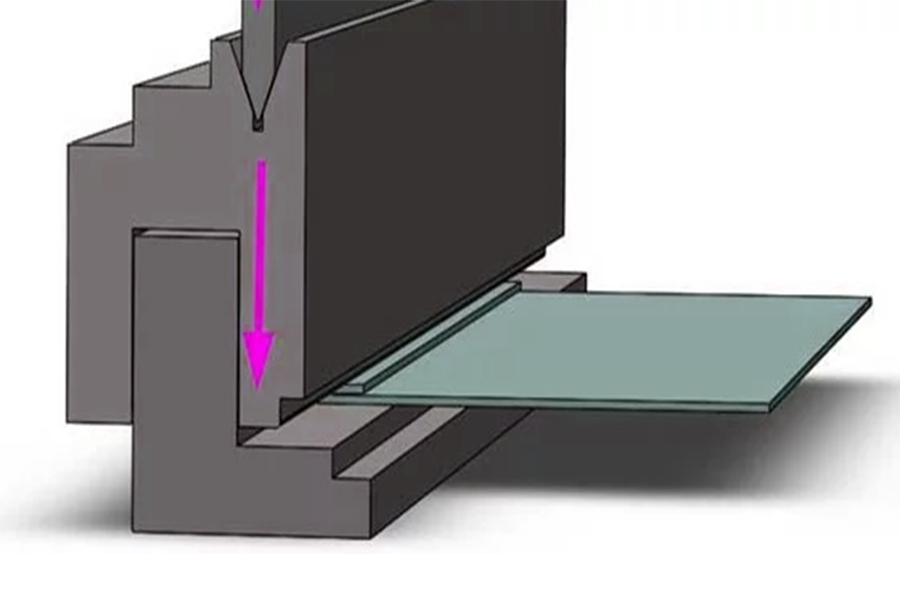

Die Hemming Process

The die hemming is most applicable for forming operations. It includes frequent software use and lots of parts shaped in a single try. It makes use of a die and press to bend the flange within the size of the pipe. The hemming is often carried out within the forming stage, whereas the flange is hemmed via a hemming software after drawing and trimming. There are additionally a number of operations within the process of hemming the shaped flange, which can additionally rely on the opening angles of the flange. This technique is helpful for creating flat and comparatively easy design panels.

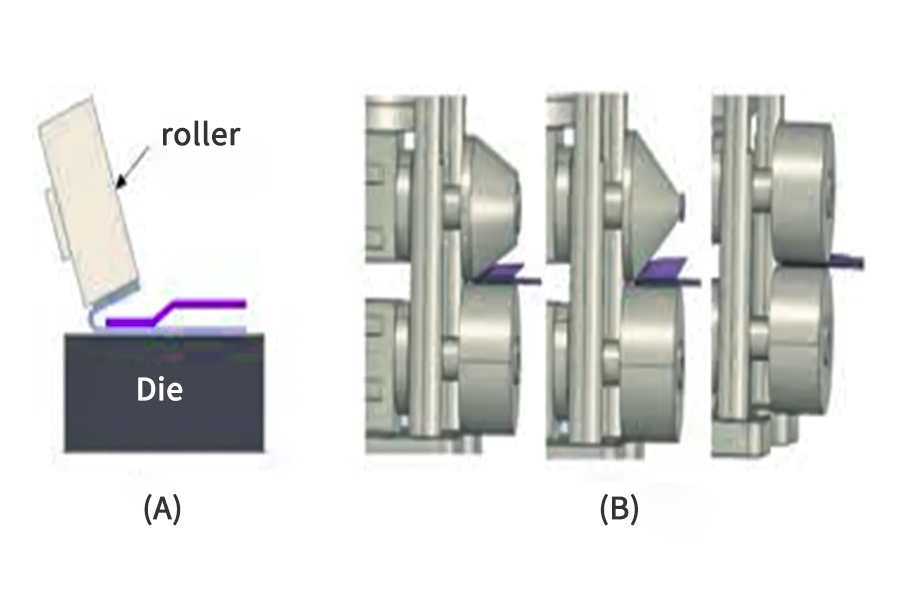

Curler Hemming Process

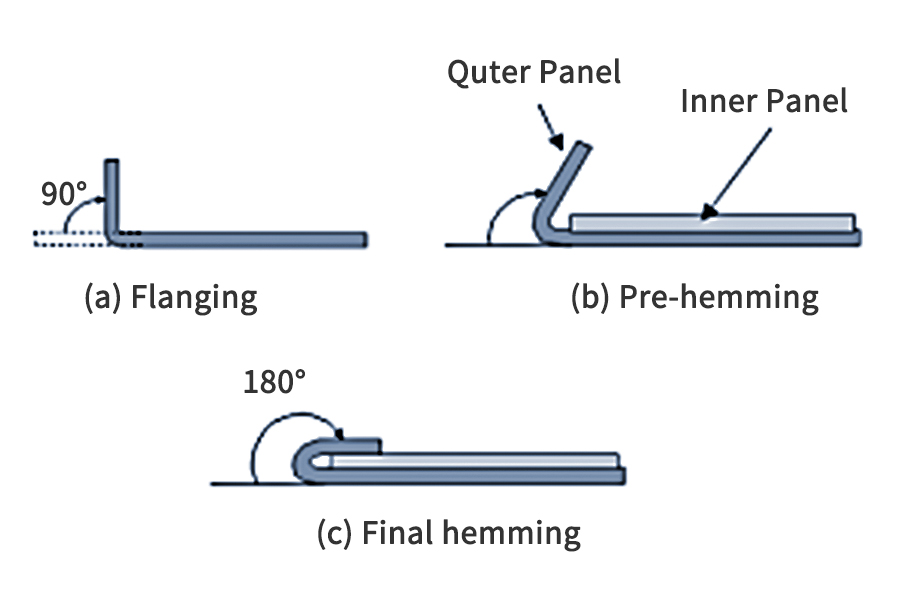

The roll or curler hemming process makes use of a hemming curler managed by an industrial robotic. This setup additionally will increase effectivity as a result of it permits for the right bending of the sheet metal edges. Moreover, it may well categorized into pre-hemming and the final hemming phases, and increments to the required angle

Nonetheless, the operation cycle time is comparatively longer, and the metal sheet orientation will be modified to lower the journey of the hemming curler. This system is advantageous for medium to giant manufacturing batches. Nonetheless, the instruments utilized in curler hemming are comparatively cheaper than these utilized in die hemming. Nonetheless, its cycle instances are normally longer than these of die hemming.

Frequent Hem Varieties In Sheet Metal Machining

Some frequent hem varieties embrace;

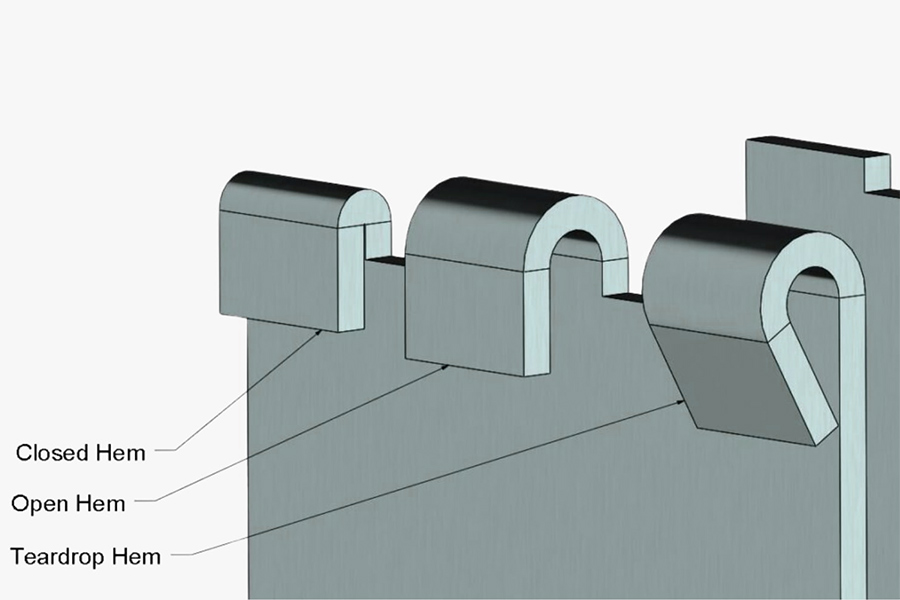

Closed Hem

An open hem just isn’t the identical as a closed or crushed hem in that though it’s pressed flat, there’s a small hole left within the fold. These hems are standard as a result of they’re simple to make: the sheet metal is bent alongside a particular airplane of the sheet metal. Nonetheless, one should contemplate that this technique additionally has materials disadvantages. Closed hems are handiest the place the thickness of the material is between 0. 040” and . 125”, as it’s clear that materials with extra thickness usually tend to crack than these with much less thickness, which is what the formulation is making an attempt to attain. The hem is created by wrapping the sheet metal across the tube to a 145-degree angle and utilizing a press brake software. You will need to word that closed hems are usually not suggested for aluminium as a result of this materials is extremely prone to cracking and breaking.

Teardrop Hem

A teardrop hem is created when the flange is bent over 180 levels. It’s useful in materials that can not be closed by hems. A teardrop hem is often thought-about applicable for aluminum sheet metal fabrication and different fragile mushy metals like stainless steel sheet metal fabrication initiatives because it presents the required reinforcement with out including further weight to parts.

Open Hem

An open hem has a curved edge on the surface and a despair in the course of the curve; subsequently, it’s applicable for handles and different parts that come into contact with folks. The open hems are most fitted when the material density is between. 040” and . 125” and have to be of a flat size a minimum of 4 instances the thickness of the fabric used. The metal is bent to 145 levels, and a shim is positioned below the fabric after which pressed to make an open hem. Open hems are typical of small sizes, for instance, 060”, 090”, 125”, 187”, and 250”.

Rolled Hem

The rolled hem is designed to attenuate the uncovered edges on sheet metal parts and make them secure. Just like the rolled hem, this sort of hem is used primarily for the perimeters of doorways. The first software of rolled hem is to eradicate sharp edges on parts in order that they’ve delicate attraction and a secure contact.

Ideas for Fantastic High quality Hemming

Listed here are basic ideas for getting required hems on sheet metals;

- Choose a fabric that can not be bent simply however will be formed simply, resembling aluminium.

- Keep away from utilizing materials that don’t flex, resembling cast iron, can also be essential.

- Sheets thicker than 0. 125 inches are extra delicate and vulnerable to cracking, in order that they have to be dealt with fastidiously.

- Measure Edges Fastidiously

- The folded edge have to be equal to thickness and have comparable curvature.

- For open hems, the bent part ought to be 4 instances the thickness of the metal used for hemming.

- For closed hems, the bent part ought to be the identical because the thickness of the fabric used.

- Use applicable Instruments

- For small bends, the usage of a press brake will be optimum.

- Use a hemming curler for extra complicated and complicated bends.

- Bend Regularly

- Bend the metal into two phases: Firstly, in a V-shape, then fold and flatten it.

- It’s optimally used to manage stress and eradicate distortion issues in parts.

Cons of Sheet Metal Hemming

Let’s focus on the disadvantages of the sheet metal hemming process;

- Time Taking Process

Sheet metal hemming is mostly time-consuming, significantly for complicated metal items. The proper software setup is critical for hemming, which may take time.

- Expert Personnel Required

Hemming nicely normally requires expert staff. These staff ought to have the ability to deal with the instruments accurately to attain the perfect outcomes with out making errors.

- Threat of Injury

When hemming is carried out incorrectly, the sheet metal will doubtless be broken. Some frequent errors embrace bending an excessive amount of or too little, which can trigger the metal to warp or develop different undesirable shapes.

Sheet Metal Jogging Vs. Sheet Metal Hemming

The primary distinction is that sheet metal hemming is a 180-degree fold, and a few hems are sealed, which means there isn’t any inside radius. If the radius is extra important than zero, then the cross-section of a hem will be described as a determine resembling the letter U.

Alternatively, sheet metal jogging includes two symmetrical bends positioned facet by facet to create a light Z offset. The thickness of the fabric used is similar as that of the channel shaped, thus a detailed match.

Sheet Metal Hem Vs Seam

Hemming is a process through which a metal edge is curved to make it easy and robust. It’s utilized to strengthen seams, defend sharp edges, and improve the look of clothes.

Conversely, seaming is utilized within the meals packaging sector, amusement park autos, and the automotive trade. Hemming and seaming are comparable in that they each entail sharp bending adopted by flattening with a flattening die. Nonetheless, seaming is commonly heavier between hem and seam because the materials are normally thicker in tonnage.

Key Takeaways

In conclusion, this text clearly explains the sheet metal hemming process and all its potential points. You need to now learn about varied sorts of hem, the strategies producers make use of to develop hems on sheet metal edges, and the best way to choose the perfect one in your metal parts.

For extra particulars, please contact our skilled engineers and technicians at JuSheng for skilled help. Our providers embrace sheet metal bending, stamping, forming, and hemming in your particular person undertaking wants. Don’t hesitate to contact us for any of your sheet metal service or sheet metal fabrication necessities.

JuSheng offers a full range of CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping for your project needs. Visit our Instant Quote Engine to get a free, no-obligation quote in minutes.

Disclaimer

The content appearing on this webpage is for informational purposes only. JuSheng makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through JuSheng’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team JuSheng

This article was written by various JuSheng contributors. JuSheng is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

FAQs

Q1. What thickness metal parts are appropriate for hemming bends?

Hemming is often applicable for parts with thicknesses within the vary of 0. 040″ to 0. 125″. For open hems, the return size of the hem is often about 4 instances the thickness of the metal. Whereas, for closed hems, this size is about 6 instances the metal thickness. Therefore, a hem’s most dimension is normally roughly 0. 75’’.

Q2. What’s the preferable size of a hem on sheet metal?

For open hems, The popular hem size ought to be between 0 and 2mm. 16 to 0. It ranges from 5 inches and will range relying on the sheet metal thickness. Closed hems typically have advised heights ranging between 0. 24 and 0. 75 inches.

Q3. Is it costly to hem sheet metal parts?

Sheet metal hemming is less expensive than different forming strategies like metal forging, casting, and stamping as a result of it requires no tooling. The price typically relies upon upon part complexity, materials kind used, and thickness required.

Pingback: Is Your Sheet Metal Customization Solution Cost Transparent? - JUSHENG