Injection molding is a popular manufacturing technique for producing plastic parts. However, this process is not without its challenges. One of the most common issues faced by injection molding manufacturers is warping deformation. This is particularly prevalent in thin-walled injection molded parts. In this article, we will provide an in-depth analysis of the factors that contribute to injection warping deformation and how to prevent it.

What is Injection Warping Deformation?

Injection warping deformation occurs when the plastic part warps during the cooling process after injection molding. This is caused by uneven shrinkage of the material as it cools, leading to changes in the dimensions and shape of the part. This can result in cosmetic defects, functional issues, and even part failure.

Factors Contributing to Injection Warping Deformation

- Material selection – The choice of material used for injection molding can greatly affect the warping deformation of the part. Materials with high shrinkage rates are more prone to warping deformation.

- Part geometry – The shape and size of the part can also contribute to warping deformation. Thin-walled parts with large surface areas are more susceptible to warping deformation.

- Injection molding process – The cooling rate, pressure, and temperature of the injection molding process can all impact the warping deformation of the part.

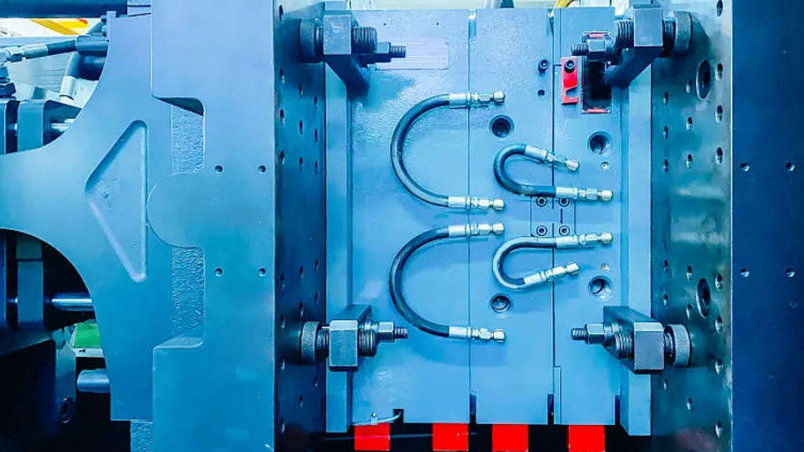

- Mold design – The design of the mold can also contribute to warping deformation. Improper venting, gating, or cooling can all lead to warping deformation.

- Part thickness – Thin-walled parts are more susceptible to warping deformation than thicker parts due to their lower rigidity.

- Flow rate – The speed at which the material flows into the mold can impact the warping deformation of the part.

- Weld lines – Weld lines are areas where two or more flows of material meet in the mold. These areas can be more prone to warping deformation.

- Post-processing – Any post-processing steps, such as painting or coating, can also impact the warping deformation of the part.

Preventing Injection Warping Deformation

- Material selection – Choose a material with a lower shrinkage rate to reduce the risk of warping deformation.

- Part design – Design the part with thicker walls and avoid large surface areas to reduce warping deformation.

- Injection molding process – Adjust the cooling rate, pressure, and temperature to minimize warping deformation.

- Mold design – Ensure proper venting, gating, and cooling to reduce warping deformation.

- Part thickness – Increase the thickness of the part to increase rigidity and reduce warping deformation.

- Flow rate – Adjust the speed of the material flow to minimize warping deformation.

- Weld lines – Avoid creating weld lines in critical areas to reduce warping deformation.

- Post-processing – Avoid any post-processing steps that could contribute to warping deformation.

Conclusion

Injection warping deformation is a common issue faced by injection molding manufacturers, particularly in thin-walled parts. However, by understanding the factors that contribute to warping deformation and taking steps to prevent it, it is possible to produce high-quality parts with minimal defects. At JS Precision, we have extensive experience in injection molding and can help you avoid warping deformation in your parts. Contact us today to learn more.