Aluminum CNC machining services are becoming more and more popular. With the continuous development and expansion of the manufacturing industry, the demand for high-precision and high-efficiency machining services is increasing. JS Precision, a professional aluminum CNC machining service manufacturer, has been at the forefront of this trend, providing the highest quality aluminum machining services to clients from all walks of life.

1. Introduce the concept and significance of aluminum CNC machining services

1.1 What is Aluminum CNC Machining Service

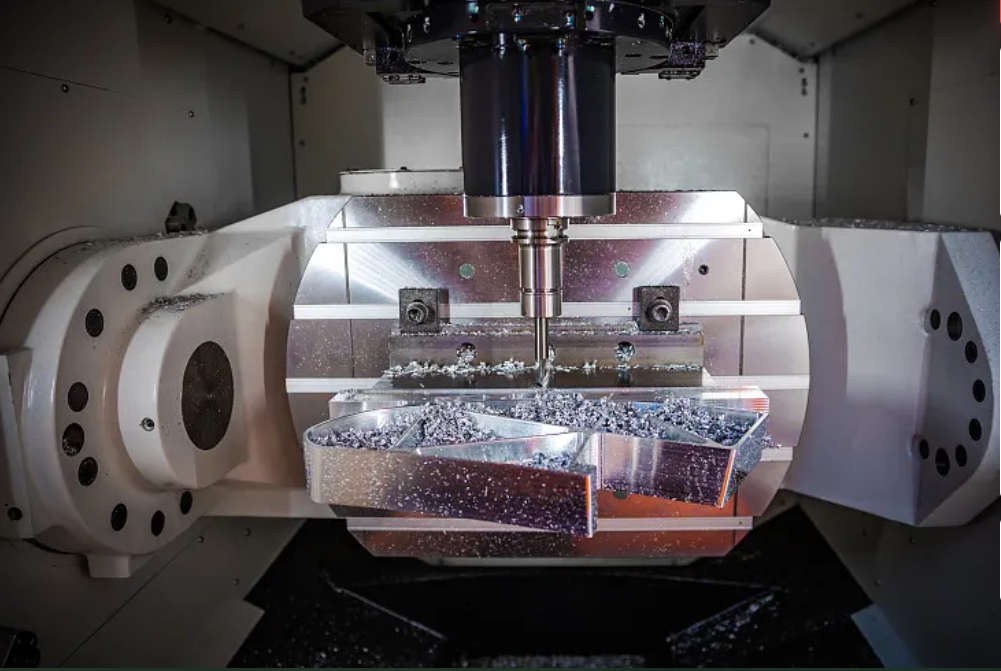

They refer to the process of using computer numerical control (CNC) machines to manufacture aluminum parts. This process involves the use of computer-controlled machines to precisely cut, shape, and form aluminum materials into a desired end product. Aluminum CNC machining services are widely used in various industries due to their precision, consistency, and efficiency.

1.2 Significance and Advantages of Aluminum CNC processing services

They offer several advantages over traditional machining methods. The use of CNC machines allows for greater precision and accuracy, resulting in higher-quality parts. Additionally, CNC machines are highly efficient and can produce parts at a faster rate than traditional machining methods. This makes aluminum CNC machining services an ideal choice for companies that require high-quality, precision parts in a short amount of time.

2. The application field of aluminum CNC processing services

2.1 Automobile Manufacturing

Aluminum CNC machining services are widely used in the automobile manufacturing industry. Aluminum is a lightweight, durable material that is commonly used in the manufacture of automobile parts. CNC machines allow for precise and consistent machining of aluminum parts, resulting in high-quality and reliable automobile components.

2.2 Manufacturing of electronic products

Aluminum CNC machining services are also used in the manufacturing of electronic products. Aluminum is an excellent conductor of heat and electricity, making it an ideal material for electronic components. CNC machines allow for the precise machining of aluminum parts, resulting in high-quality and reliable electronic components.

2.3 Aerospace Manufacturing

Aluminum CNC machining services are widely used in the aerospace manufacturing industry. Aluminum is a lightweight, strong material that is commonly used in the manufacture of aircraft parts. CNC machines allow for precise and consistent machining of aluminum parts, resulting in high-quality and reliable aircraft components.

2.4 Machinery Manufacturing

Aluminum CNC machining services are also used in the manufacturing of machinery. Aluminum is a strong and durable material that is commonly used in the manufacture of machinery parts. CNC machines allow for precise and consistent machining of aluminum parts, resulting in high-quality and reliable machinery components.

3. Process flow of aluminum CNC machining service

3.1 Design and manufacture

The first step in aluminum CNC machining services is the design and manufacture of the part. This involves creating a 3D model of the part using computer-aided design (CAD) software. The design is then turned into a digital file that can be read by the CNC machine.

3.2 CNC programming

The next step in aluminum CNC machining services is CNC programming. This involves creating a set of instructions that tell the CNC machine how to cut, shape, and form the aluminum material into the desired part. The CNC programmer uses specialized software to create these instructions.

3.3 Processing and testing

The final step in aluminum CNC machining services is processing and testing. This involves setting up the CNC machine and running the part through the machining process. Once the part has been machined, it is inspected and tested to ensure that it meets the required specifications.

4. Technical requirements for aluminum CNC processing services

4.1 Equipment requirements

To provide high-quality aluminum CNC machining services, it is essential to have the right equipment. This includes CNC machines, cutting tools, and measuring equipment. The equipment must be maintained and calibrated regularly to ensure that it is always in top condition.

4.2 Material requirements

The quality of the aluminum material used in the machining process is also essential. High-quality aluminum materials will result in high-quality parts. It is essential to source aluminum material from reputable suppliers to ensure that it meets the required specifications.

4.3 Technical requirements

To provide high-quality aluminum CNC machining services, technical expertise is also essential. This includes knowledge of CNC programming, cutting tools, and measuring equipment. The CNC programmer must be able to create accurate and precise machining instructions, while the machinist must have the skills to operate the CNC machine and produce high-quality parts.

5. Market Prospect and Development Trend of Aluminum CNC Processing Services

5.1 Market prospect

The demand for high-quality, precision parts is growing across various industries. As such, the market for aluminum CNC machining services is expected to grow significantly in the coming years. Companies that provide high-quality aluminum CNC machining services are well-positioned to take advantage of this growing demand.

5.2 Development Trend

The development trend of aluminum CNC processing services is towards greater automation and efficiency. This includes the use of advanced software and robotics to streamline the machining process.