introduction:

With the continuous development of science and technology, the application of thin-wall molding technology has become more and more extensive, and it has become an important technology in the production of precision plastics. Thin-wall molding can not only improve product quality and reduce production costs, but also meet market demand for lightweight, high-strength, and high-precision plastic products. This article will deeply discuss the advantages of thin-wall molding in the production of precision plastics, and analyze it with the actual case of JS Precision.

Definition and development history of thin-wall forming

Thin-wall molding is a molding technology that controls the wall thickness of plastic products below 0.5mm. This technology originated in Europe in the 1950s. With the continuous development of the plastics industry, thin-wall molding technology has gradually become an important production technology. At present, thin-wall molding has become an important method of plastic product production and is widely used in food packaging, medical equipment, automobiles, electronics, and other fields.

Application fields of thin-wall forming technology

The application fields of thin-wall forming technology are very wide, including but not limited to food packaging, medical equipment, automobiles, electronics, and other fields. In the field of food packaging, thin-wall forming technology can produce lightweight, high-strength, and high-transparency food packaging boxes, which improves the freshness and portability of food. In the field of medical devices, thin-wall molding technology can produce precision medical devices, such as syringes, infusion sets, etc., which improves the precision and safety of medical devices. In the automotive field, thin-wall molding technology can produce lightweight, high-strength, high-heat-resistant auto parts, such as lights, front bumpers, etc., which improves the safety and fuel efficiency of cars. In the field of electronics, thin-wall molding technology can produce thin, high-precision electronic product casings, such as mobile phones, tablet computers, etc., which improves the aesthetics and performance of electronic products.

Advantages of the thin-wall molding in precision plastic production

Material saving: Thin-wall molding technology can control the wall thickness of products below 0.5mm, which can reduce the amount of materials used and production costs compared with traditional molding technology.

Improve production efficiency: Thin-wall forming technology can shorten the production cycle of products and improve production efficiency.

Product quality improvement: Thin-wall forming technology can produce products with high precision, high strength and high heat resistance, which improves the quality and performance of products.

Cost reduction: Thin-wall forming technology can reduce production costs and improve the competitiveness of enterprises.

The development trend of thin-wall-forming technology

With the market’s increasing demand for lightweight, high-strength, and high-precision plastic products, thin-wall molding technology will be more and more widely used in future development. At the same time, with the continuous advancement of science and technology, the thin-wall forming technology will also be continuously upgraded to improve the forming accuracy and efficiency.

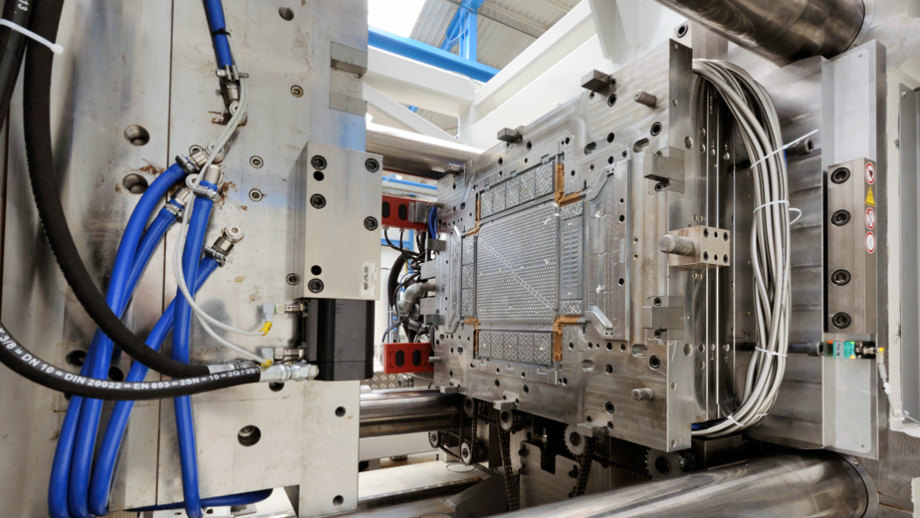

Application of thin-wall forming technology in JS Precision

JS Precision is a professional manufacturer of precision plastic products, with advanced thin-wall molding technology and complete production equipment. JS Precision’s products cover food packaging, medical equipment, automobiles, electronics, and other fields. In terms of thin-wall forming technology, JS Precision has rich experience and technical advantages and can provide customers with high-quality, high-performance thin-wall forming products.

Application of JS Precision thin-wall forming technology in auto parts manufacturing

Taking the front bumper of a car as an example, the traditional front bumper needs to use thick-wall molding technology, and the wall thickness is generally about 2-3mm, while JS Precision uses thin-wall molding technology to control the wall thickness below 1mm, which greatly reduces the material cost. usage, reducing production costs. At the same time, thin-wall molding technology can reduce the weight of the front bumper by 30%, improving the fuel efficiency and safety of the car.

Combined with market demand, the future development of JS Precision thin-wall forming technology

With the market’s increasing demand for lightweight, high-strength, and high-precision plastic products, JS Precision will continue to strengthen the research and development of thin-wall molding technology, continuously improve molding accuracy and efficiency, and meet market demand.

Conclusion

Thin-wall molding technology has important application value in the production of precision plastics, which can improve product quality, reduce production costs, and meet market demand. JS Precision has rich experience and technical advantages in thin-wall forming technology, and can provide customers with high-quality, high-performance thin-wall formed products. Welcome to contact JS Precision for quotation.