Introduction

Computer Numerical Control machining, or CNC machining, is a manufacturing process that utilizes pre-programmed computer software to carry out a multitude of machining operations. It can create intricate parts and components with a high degree of accuracy and precision. CNC machining is ideal for producing complex geometries and specialized parts that would be difficult or impossible to make with traditional machining methods. In this blog post, we will explore how CNC machining makes it possible to manufacture complex geometries and specialized parts with ease.

Capabilities of CNC Machining

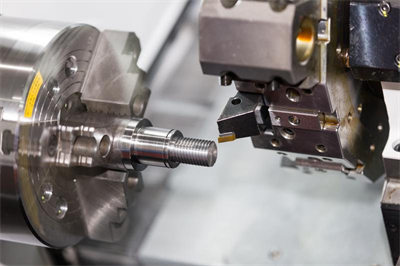

CNC machining has numerous capabilities that make it an essential technology for modern manufacturing. One of its key advantages is its ability to produce complex geometries with ease. CNC machines can create intricate shapes and contours that would be difficult or impossible to make with traditional machining techniques. This is because CNC machines use computer software to precisely control cutting tools, allowing them to move in multiple axes and create complex shapes.

Another advantage of CNC machining is its ability to produce specialized parts with precision and accuracy. CNC machines can work with a wide range of materials, including metals, plastics, and composites. CNC machines can also work with very tight tolerances, ensuring that parts meet exact specifications. This makes CNC machining ideal for producing specialized parts for industries such as aerospace, medical, and automotive.

Applications of CNC Machining

CNC machining has numerous applications in various industries. In aerospace, CNC machining is used to create complex parts for aircraft engines, landing gear, and other critical components. In the medical industry, CNC machining is used to produce precision parts for surgical tools, medical devices, and implants. In the automotive industry, CNC machining is used to create parts for engines, transmissions, and other critical systems.

CNC machining is also used in the production of consumer goods, such as electronics, appliances, and toys. CNC machines can create precise and intricate parts for these products, ensuring that they function correctly and are aesthetically pleasing. In addition, CNC machining is used in the production of prototypes and small runs of specialized parts, allowing manufacturers to quickly and efficiently test new designs and products.

The Future of CNC Machining

With the continued advancements in computer software and automation, CNC machining is set to revolutionize the manufacturing industry. The use of artificial intelligence (AI) and machine learning will enable CNC machines to become smarter and more efficient in their operations. This will lead to increased productivity, reduced costs, and faster lead times for the production of complex geometries and specialized parts.

Furthermore, the use of 3D printing technology in conjunction with CNC machining will allow manufacturers to create parts with even greater precision and complexity. 3D printing can produce intricate designs that would be nearly impossible to create with traditional machining techniques. When combined with CNC machining, these designs can be refined and perfected to an even greater extent.

Conclusion

CNC machining is an essential technology for modern manufacturing. Its ability to produce complex geometries and specialized parts with precision and accuracy makes it ideal for a wide range of industries. Whether it’s aerospace, medical, automotive, or consumer goods, CNC machining plays a vital role in the production of high-quality and innovative products. With the continued advancements in computer software and automation, as well as the integration of 3D printing technology, CNC machining is poised to revolutionize the manufacturing industry for years to come.