Introduction

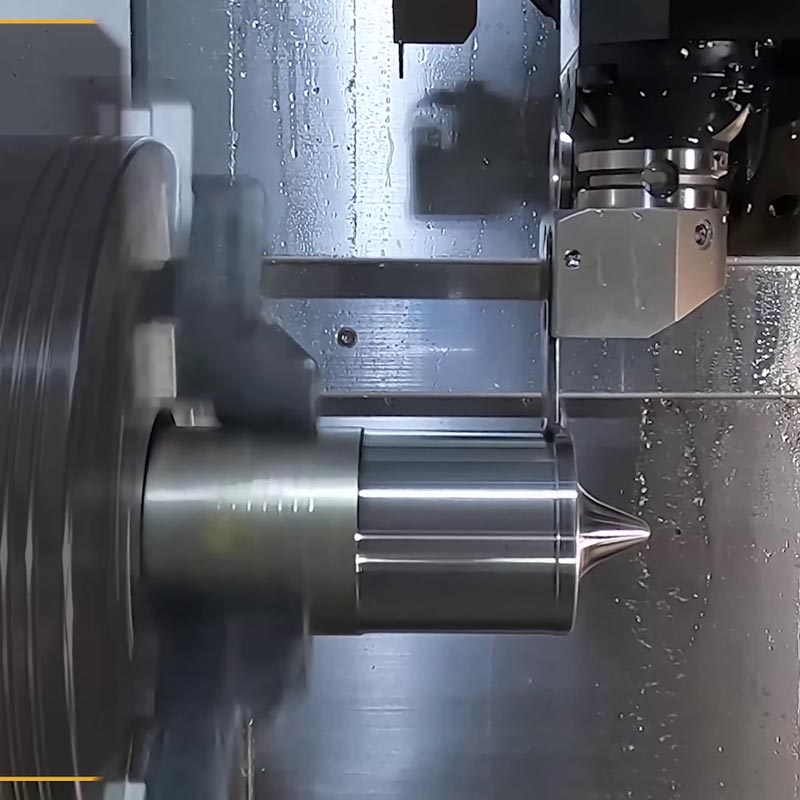

CNC machining has revolutionized the manufacturing industry in numerous ways, providing a wide range of possibilities in terms of accuracy, speed, and complexity. One of the most critical aspects of any CNC machining project is the selection of materials. Whether you’re working on a prototype or mass production, choosing the right materials can make a significant difference in the quality and cost of your project. In this blog post, we’ll discuss the importance of selecting the right materials and explore some of the most commonly used materials in CNC machining.

Importance of Material Selection

The materials used in CNC machining have a significant impact on the quality, cost, and durability of the final product. The right material selection can result in a product that meets all of the requirements while remaining within budget. In contrast, choosing the wrong material can lead to a costly and time-consuming process of re-engineering the product. The choice of materials is also essential to ensure that the product meets regulatory requirements and industry standards.

Factors to Consider when Choosing Materials

The following factors should be considered when selecting materials for CNC machining:

Application:

The intended use of the product should be the primary factor when selecting materials. The material’s properties should match the product’s application requirements, such as strength, hardness, or flexibility.

Project Requirements:

The project requirements, such as the level of precision or complexity required, should also influence the choice of materials. Some materials are more suitable for specific processes, such as laser cutting or water jet cutting.

Budget:

The budget is another critical factor when selecting materials for CNC machining. Some materials are more expensive than others, and the cost can vary depending on the quantity required.

Commonly Used Materials in CNC Machining

Aluminum

Aluminum is one of the most popular materials used in CNC machining. It’s lightweight, durable, and has excellent thermal conductivity. This makes it an ideal choice for a wide range of applications, including aerospace, automotive, and consumer electronics. Aluminum can also be easily machined and comes in a variety of grades, each with unique properties that make them suitable for different applications.

Stainless Steel

Stainless steel is another popular material used in CNC machining. It’s known for its excellent corrosion resistance, strength, and durability. Stainless steel is a versatile material that can be machined into a variety of shapes and sizes. It’s commonly used in the medical, aerospace, and automotive industries.

Plastics

Plastic materials are widely used in CNC machining. They’re lightweight, inexpensive, and come in a variety of colors and textures. Plastics can also be machined into complex shapes and sizes, making them ideal for prototyping and mass production. Some of the most commonly used plastics in CNC machining include acetal, nylon, and polycarbonate.

Other Materials Used in CNC Machining

While aluminum, stainless steel, and plastics are some of the most commonly used materials in CNC machining, there are many other materials to choose from, such as brass, copper, titanium, and composites. The choice of materials depends on the specific project requirements and the budget.

Conclusion

Choosing the right materials for CNC machining is critical to the success of any project. The materials you choose can impact the quality, cost, and durability of your parts. The selection process requires attention to detail and an understanding of the properties and characteristics of different materials. While aluminum, stainless steel, and plastics are some of the most commonly used materials in CNC machining, there are many other materials to choose from. Consider your application, project requirements, and budget when selecting materials for your CNC machining project.