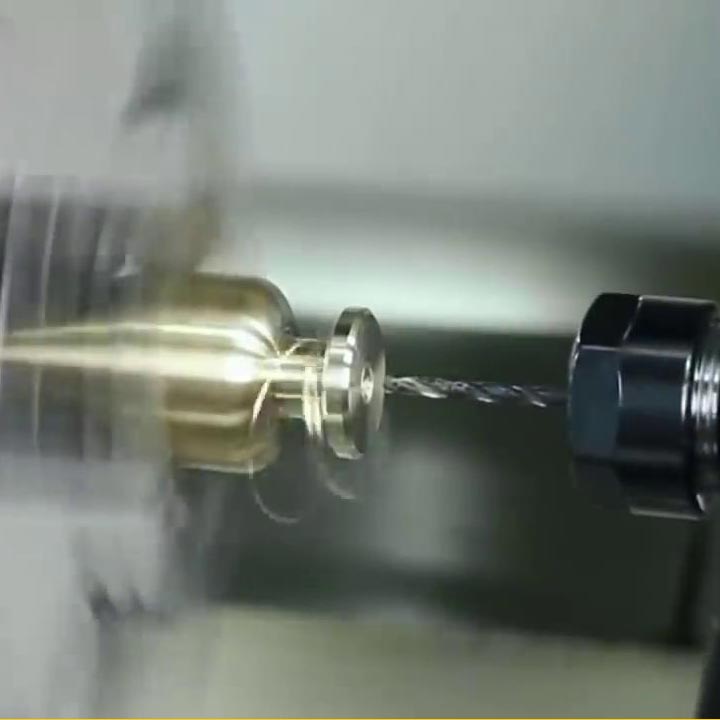

Computer Numerical Control (CNC) machines have revolutionized the manufacturing industry. CNC machining has made it possible to create complex and precise parts with ease. CNC machines are used in various industries, including aerospace, automotive, medical, and more. The machines have automated the manufacturing process, making it faster, more efficient, and cost-effective.

Here are some of the benefits of CNC machining for industrial manufacturing:

High Precision and Accuracy

One of the biggest advantages of CNC machining is the precision and accuracy of the parts produced. The machines are computer-controlled, which means that they can achieve high levels of precision and accuracy. CNC machines can create parts with tolerances as low as 0.001mm. The high precision and accuracy of CNC machines make them ideal for creating complex parts that require tight tolerances. CNC machines can produce parts that are identical, which is crucial for mass production.

The precision and accuracy of CNC machines can also result in cost savings. With traditional manual machines, errors and mistakes can occur, which can cause delays and additional costs. CNC machines, on the other hand, are programmed to produce parts with high precision and accuracy, which reduces the likelihood of errors.

Increased Efficiency and Productivity

CNC machines are incredibly efficient and productive. They can work continuously, 24 hours a day, 7 days a week, without stopping. CNC machines can produce parts at a faster rate than manual machines, which means that production time is reduced. Machines can also perform multiple tasks simultaneously, which increases productivity.

CNC machines are programmed to perform specific tasks, which eliminates the need for manual intervention. This means that operators can focus on other tasks, which further increases productivity. Machines can also be programmed to perform tasks that would be difficult or impossible to perform manually. For example, CNC machines can create parts with intricate designs, which would be challenging to produce with manual machines.

Reduced Labor Costs

CNC machines have automated the manufacturing process, which reduces the need for manual labor. The machines can perform tasks that would require multiple operators on manual machines. This means that companies can reduce their labor costs significantly. CNC machines also eliminate the need for skilled labor, as the machines are computer-controlled. This means that companies can hire less skilled operators, which reduces labor costs even further.

In addition to reducing labor costs, CNC machines can also reduce material waste. With traditional manual machines, errors and mistakes can result in wasted materials. CNC machines, on the other hand, are programmed to produce parts with high precision and accuracy, which reduces the likelihood of errors and waste.

Improved Safety

CNC machines can also improve workplace safety. With traditional manual machines, operators are required to perform tasks that can be dangerous. For example, operators may need to work with sharp tools or in close proximity to moving parts. CNC machines, on the other hand, are programmed to perform these tasks automatically, which reduces the risk of injury to operators.

Increased Flexibility

CNC machines can also increase flexibility in the manufacturing process. The machines can be programmed to produce different parts with ease. This means that companies can quickly switch between different parts without having to retool the machines. This flexibility can be especially beneficial for companies that produce a variety of parts in small quantities.

Conclusion

CNC machining has revolutionized the manufacturing industry. The high precision and accuracy of CNC machines make them ideal for creating complex parts that require tight tolerances. The machines are incredibly efficient and productive, which reduces production time. CNC machines have also reduced labor costs significantly. Companies that have invested in CNC machines have seen an increase in productivity, efficiency, and cost savings.

CNC machines are not only beneficial for large companies but also for small and medium-sized enterprises. As technology continues to advance, we can expect to see even more benefits from CNC machines. Companies that invest in CNC machines now will be well-positioned to take advantage of the benefits of this technology in the future.

In summary, the benefits of CNC machining for industrial manufacturing include high precision and accuracy, increased efficiency and productivity, reduced labor costs, improved safety, and increased flexibility.