Introduction

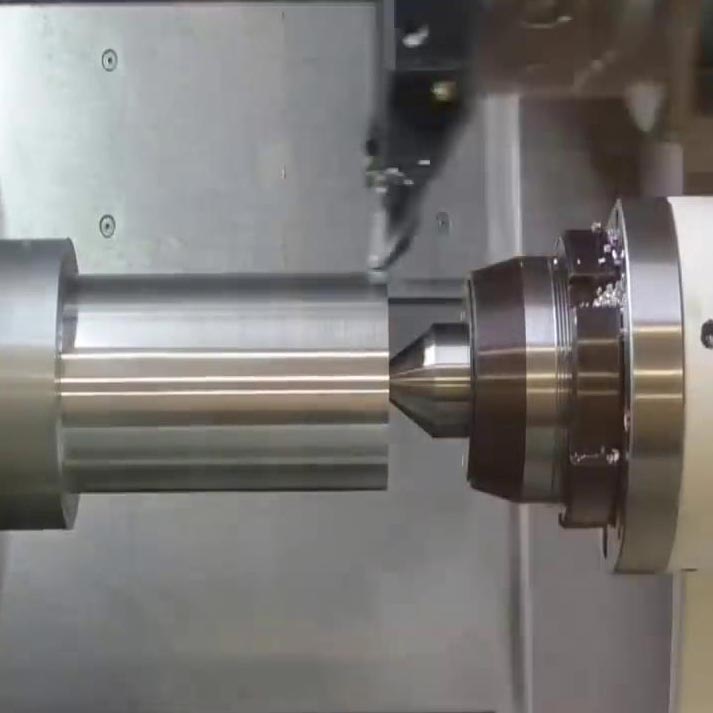

CNC machining has revolutionized the manufacturing industry by providing highly accurate and efficient production capabilities. Traditional manufacturing methods like injection molding are not always feasible solutions for low-volume production runs. That’s where CNC machining comes into play. CNC machining is an excellent option for low-volume production runs because it offers a cost-effective and rapid solution for producing parts in small quantities.

Benefits of CNC Machining for Low-Volume Production

CNC machining is an ideal solution for low-volume production runs because of the following benefits:

Cost-effective

CNC machining is a cost-effective solution for low-volume production runs because the setup costs are relatively low when compared to other manufacturing methods. Unlike injection molding or die casting, CNC machining does not require expensive molds or tooling. Instead, CNC machines use computer-controlled tools to manufacture parts, which means that there are no additional costs associated with changing the tooling for different parts. This makes CNC machining an excellent option for small businesses or startups that need to produce low volume production runs without breaking the bank.

Rapid Turnaround Time

CNC machining is a rapid solution for low-volume production runs because the setup time is short. CNC machines can be programmed quickly and can produce parts in a matter of hours, depending on the complexity of the parts. This is a significant advantage over traditional manufacturing methods, which can take weeks or even months to produce parts. CNC machining allows manufacturers to produce parts quickly and cost-effectively, which is essential in today’s fast-paced business environment.

High Precision and Accuracy

CNC machines are highly precise and accurate, which makes them an ideal solution for manufacturing complex parts with tight tolerances. CNC machines use computer-controlled tools to manufacture parts, which ensures that each part is produced to the exact specifications. This level of precision and accuracy is difficult to achieve with traditional manufacturing methods. CNC machines can produce parts with tolerances as low as 0.001 inches, which makes them an essential tool for producing parts with high precision requirements.

Versatility

CNC machining is a versatile manufacturing method that can be used to produce a wide range of parts for various industries. CNC machines can produce parts from a wide range of materials, including metals, plastics, and composites. This versatility makes CNC machining an essential tool for modern manufacturing.

Low Waste

CNC machining is a highly efficient manufacturing method that produces minimal waste. Unlike traditional manufacturing methods, which can produce a significant amount of scrap material, CNC machines are highly precise and accurate, which means that they produce parts with minimal waste. This is an important consideration for companies that are looking to reduce their environmental impact and save on material costs.

Applications of CNC Machining for Low-Volume Production

CNC machining is a versatile manufacturing method that can be used to produce a wide range of parts for various industries. Here are some examples of applications of CNC machining for low-volume production:

Aerospace

CNC machining is used extensively in the aerospace industry to produce high-precision parts with complex geometries. These parts include turbine blades, impellers, and other critical components that require high accuracy and precision. CNC machining allows aerospace manufacturers to produce parts quickly and cost-effectively, which is essential in an industry that requires high levels of precision and accuracy.

Medical Devices

CNC machining is also used in the medical device industry to produce low-volume production runs of custom parts for surgical instruments, implants, and prosthetics. CNC machining allows manufacturers to produce parts with complex geometries that are difficult to achieve with traditional manufacturing methods. CNC machining is an essential tool for medical device manufacturers because it allows them to produce parts quickly and cost-effectively, which is critical in an industry where time is of the essence.

Automotive

CNC machining is used in the automotive industry to produce parts for prototypes, concept cars, and low-volume production runs of specialty vehicles. CNC machining allows manufacturers to produce parts quickly and cost-effectively, which is essential for the fast-paced automotive industry. CNC machining is an essential tool for automotive manufacturers because it allows them to produce parts with complex geometries and tight tolerances, which are required for high-performance vehicles.

Consumer Goods

CNC machining is also used in the consumer goods industry to produce parts for various products, including electronics, appliances, and toys. CNC machining allows manufacturers to produce parts quickly and cost-effectively, which is essential in a highly competitive industry that requires fast turnaround times. CNC machining is an essential tool for consumer goods manufacturers because it allows them to produce parts with high precision and accuracy, which is required for products with complex geometries.

Prototyping

CNC machining is an excellent solution for prototyping because it allows manufacturers to produce parts quickly and cost-effectively. CNC machines can produce parts from a wide range of materials, including metals, plastics, and composites, which makes them an ideal tool for rapid prototyping.

Replacement Parts

CNC machining is also an excellent solution for producing replacement parts for machinery and equipment. Often, replacement parts are no longer available from the original equipment manufacturer, which can be a significant problem for companies. CNC machining allows companies to produce replacement parts quickly and cost-effectively, which can save them time and money.

Conclusion

CNC machining is an excellent option for low-volume production runs because it offers a cost-effective and rapid solution for producing parts in small quantities. CNC machining is highly precise and accurate, which makes it an ideal solution for manufacturing complex parts with tight tolerances. With its versatility and wide range of applications, CNC machining is an essential tool for modern manufacturing. Whether you are in the aerospace, medical device, automotive, consumer goods, or prototyping industry, CNC machining can help you produce high-quality parts quickly and cost-effectively.