We are able to see the stainless parts all over the place, from screws for furnishings to automotive & medical parts. These functions are manufactured utilizing totally different strategies, together with stainless steel machining, metal fabrication, casting, and forging. The machining operations take away the fabric from the stainless steel workpiece utilizing appropriate slicing instruments till the specified form is fashioned.Cutting, milling, turning, drilling, grinding, and different machining processes are utilized to the stainless steel in accordance with the design of the meant parts. This text will elaborate on the totally different stainless steel machining strategies, functions, and many others.

Table of Contents

ToggleIntroduction to Stainless Steel Machining

Stainless steel is a high-strength and corrosion-resistant alloy with a minimal of 10.2 % chromium and 1.2 % carbon. It may be machined with each standard machining tools and superior CNC machines. Standard machining of stainless steel includes manually working machines like lathes and standard milling machines, which is usually time-consuming and requires knowledgeable operators. Consequently, standard machines are delicate to precision; they will obtain a tolerance of ±0.13 to 0.25 mm with stainless steel. In the meantime, stainless steel CNC machining makes use of a computer-controlled process that may automate the instrument motion for exact machining sooner than handbook machining. Listed here are the steps of manufacturing CNC machined stainless steel parts;- Designing: CAD design with detailed options, dimensioning, and tolerance in laptop design software program.

- G/M code: The CAM software program converts the CAD design into G or M-codes, and the knowledge is readable by CNC machining. It’s primarily for controlling the instrument motion in an optimum machining path.

- Device & Workpiece Setup: The suitable slicing instrument is fastened within the spindle and stainless steel workpiece within the work desk or chuck.

- Machining: The slicing instrument follows the directed path routinely till the meant geometry is fashioned.

- Publish-Processing: Surface finishing like grinding, plating, or bead blasting is utilized for improved smoothness.

Stainless Steel Machining Grades

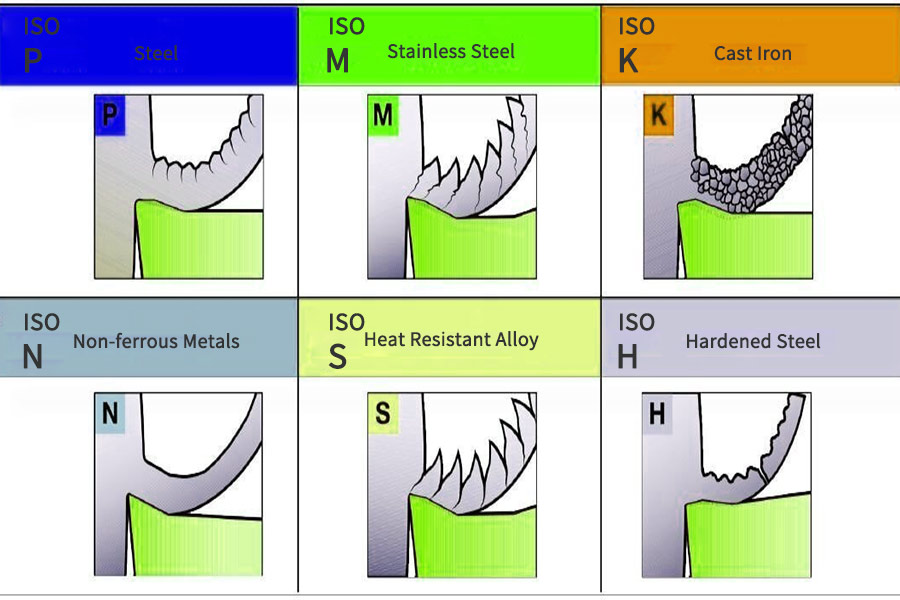

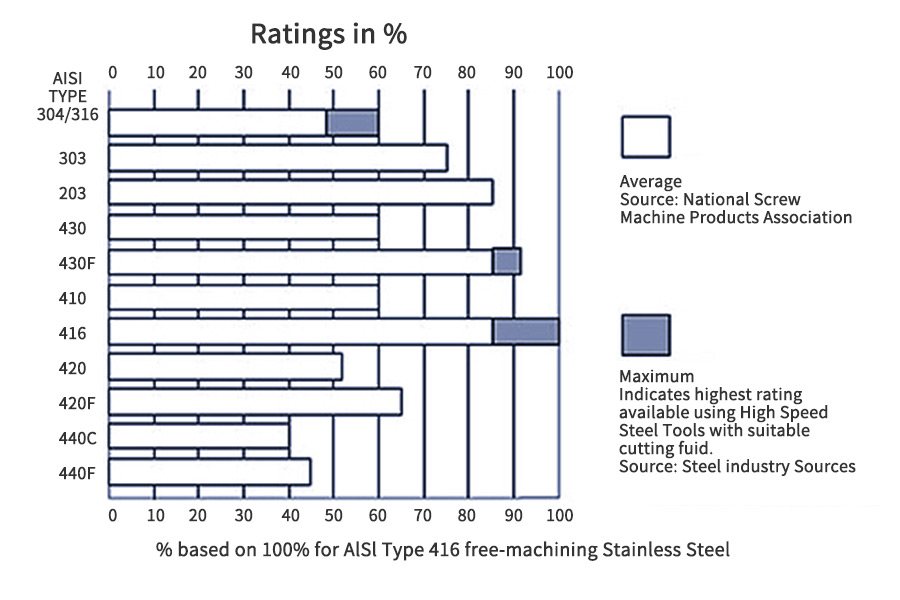

Nearly all stainless steel grades are suitable with CNC machining processes, and a few are free-machining grades. This implies modified grades with excessive machinability, corresponding to 303, 316, 403F, and 430F. The free-machining stainless steel grades are made by including sulfur, selenium, or different components that act as chip breakers and lubricants throughout the machining process.

Nearly all stainless steel grades are suitable with CNC machining processes, and a few are free-machining grades. This implies modified grades with excessive machinability, corresponding to 303, 316, 403F, and 430F. The free-machining stainless steel grades are made by including sulfur, selenium, or different components that act as chip breakers and lubricants throughout the machining process.- 303 Stainless Steel (UNS S30300)

- 304 Stainless Steel (UNS S30400)

- 316 Stainless Steel (UNS S30400

- 310S Stainless Steel (UNS S31008)

- 416 Stainless Steel (UNS S41600)

- 420F Stainless Steel (UNS S42020)

- 430FSe Stainless Steel (UNS S43023)

- 17-4 PH Stainless Steel (UNS S17400)

- 304L Stainless Steel (UNS S30403)

- 316L Stainless Steel (UNS S31603)

Kinds of Stainless Steel Machining

Furthermore, the frequent varieties of stainless steel machining operations are laser slicing, milling, drilling, turning, and grinding;Stainless Steel Laser Cutting Though each fiber and CO2 laser cutters can lower stainless steel, Fiber lasers are most popular on account of their pace and precision. Laser slicing stainless steel includes utilizing a extremely intense laser beam focused within the slicing place, which melts or vaporizes the metal to create a clear lower. The facility of the laser is dependent upon the thickness of the Stainless Steel Sheet Metal.Stainless Steel CNC Milling In stainless steel CNC milling, the workpiece is fastened on a desk, and rotating cutters form it in accordance with the programmed design. This extremely versatile machine performs slicing, profiling, drilling, slotting, and contouring operations with applicable tooling. The standard tolerance of milling stainless steel is 0.13 mm, however it may be as little as 0.05 mm. Subsequent, CNC stainless steel milling can produce complicated parts for numerous industrial functions, from automotive parts to food-processing tools.Stainless Steel CNC Turning Within the turning kind of stainless steel machining, a steel workpiece is rotated as an alternative of the slicing instrument, eradicating materials to form it into the designed geometry. It’s excellent for axially symmetric stainless steel parts corresponding to shafts and bushings. Moreover, CNC lathes or Turing machines are used for this machining process.Stainless Steel CNC Drilling A CNC drilling machine makes use of carbide or diamond-coated drill bits to create deep holes in stainless steel workpieces. Drilling stainless steel machining primarily offers with cylindrical holes of various diameters. It’s generally used to fabricate parts that require exact holes, corresponding to printed circuit boards (PCBs), engine parts, and industrial parts and tools.Stainless Steel CNC GrindingIt’s the post-processing step by which CNC-machined stainless steel parts are fed right into a rotating grinding wheel containing an abrasive layer on high. This process removes minor materials from the stainless steel surface and removes surface defects and irregularities for a clean ( as much as 0.13 μm) and uniform surface. The frequent abrasives for stainless steel grinding are Aluminum Oxide (Al2O3), Zirconia Alumina, and Silicon Carbide (SiC).In the meantime, the grain-size distribution for grinding stainless steel is as follows;- Coarse Grit (16 – 60): Preliminary fast materials elimination, tough grinding.

- Medium Grit (80 – 180): Intermediate grinding to arrange surfaces for additional finishing, corresponding to anodizing or plating.

- Very High quality Grit (800 – 3000): This high-gloss finishing method removes high quality scratches and achieves a mirror-like end.

Functions of Stainless Steel Machining in Totally different Industries

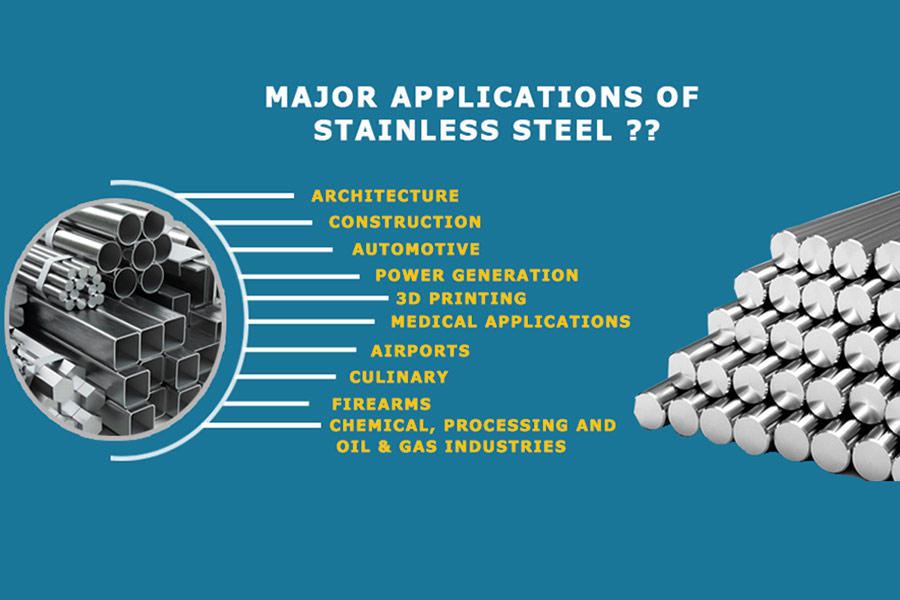

Stainless steel machining is utilized in functions requiring excessive power, corrosion, and put on resistance. Carbon-grade steels are additionally appropriate for ductile parts and merchandise. Furthermore, this manufacturing technique is versatile with manufacturing quantity, from fast prototyping to large-scale manufacturing runs.The applying examples of machining stainless steel are as follows;- Aerospace: Plane engine parts, touchdown gear parts, fasteners, hydraulic system parts, turbine blades, warmth shields, gas system parts, and many others.

- Automotive: Exhaust system parts, gear shafts, engine valves, chassis parts, gas injectors, suspension parts, and many others.

- Medical: Surgical devices, implants, hypodermic needles, cardiovascular stents, medical furnishings, and many others.

- Meals Processing: Storage tanks, conveyors, slicing and slicing instruments, filling & packaging equipment, warmth exchangers, mixer tools, and many others.

- Oil and Gasoline: Excessive-pressure pump parts, valve our bodies, downhole instruments, flanges & connectors, drilling tools parts, and many others.

- Electronics: Warmth sinks, enclosures, PCB helps, mounting brackets, and many others.

- Marine: Engine parts, propeller shafts, deck {hardware}, hull fittings, steering parts, and many others.

Challenges of Stainless Steel Machining

Though stainless steel machining has a number of advantages, its hardness, fast hardening on account of warmth build-up, and poor surface finishing are the primary challenges within the machining process. Nonetheless, these might be addressed or resolved with countermeasures.Desk: Challenges in Stainless Steel Machining| Problem | Description | Resolution |

| Machinability | The fast hardening properties trigger fast instrument put on. | Customized instrument design & materials for stainless steel machining |

| Overheating | Its low warmth conductivity results in fast overheating and impacts each the fabric and the instruments. | Use low-speed instruments (below 4000 rpm) to reduce warmth buildup |

| Extended Process | The hardness and power make stainless steel machining slower. | Choose the fitting instruments and slicing pace |

| Reaching Good End | Attaining an ideal end on stainless steel is troublesome | Use sharp and exact instruments. There are not any shortcuts to attaining a high-quality end. |

Manufacture your Stainless Steel Parts at JuSheng

The CNC manufacturing of stainless steel requires an understanding of fabric properties and an applicable choice of machining instruments. At JuSheng, our knowledgeable engineers work carefully with shoppers to grasp the necessities and execute the machining with superior multi-axis CNC tools.Moreover, our expertise collaborating with automotive, aerospace, medical, industrial processing, and different numerous industries might help you be aggressive out there. Our intensive community of material-supply chains and superior CNC infrastructure scale back machining prices considerably in comparison with Western corporations.Thus, ship us your engineering design with the undertaking’s required specs to leverage our stainless steel machining companies. We are going to get again to you with an in depth quote and additional planning on your undertaking.Key Takeaways

- Stainless steel is a high-strength, corrosion-resistant alloy that may be machinable with standard and superior CNC tools.

- The frequent machining sorts are milling, turning, drilling, grinding and laser slicing.

- Attributable to added components corresponding to sulphur and selenium, free-machining grades like 303, 316, 416, and 430F are modified for higher machinability.

- The functions are broadly utilized in aerospace, automotive, medical, meals processing, oil and fuel, electronics, marine, and plenty of extra industries.

- Some potential challenges in machining stainless steel embrace poor machinability, overheating, lengthy cycle time, and ideal end.