When it comes to manufacturing products, many people can’t decide whether to use CNC machining or injection molding to create their custom parts, choosing the right process is crucial, the decision can be complex, use this guide to decide if CNC machining or injection molding is right for your project!

What Is Injection Molding?

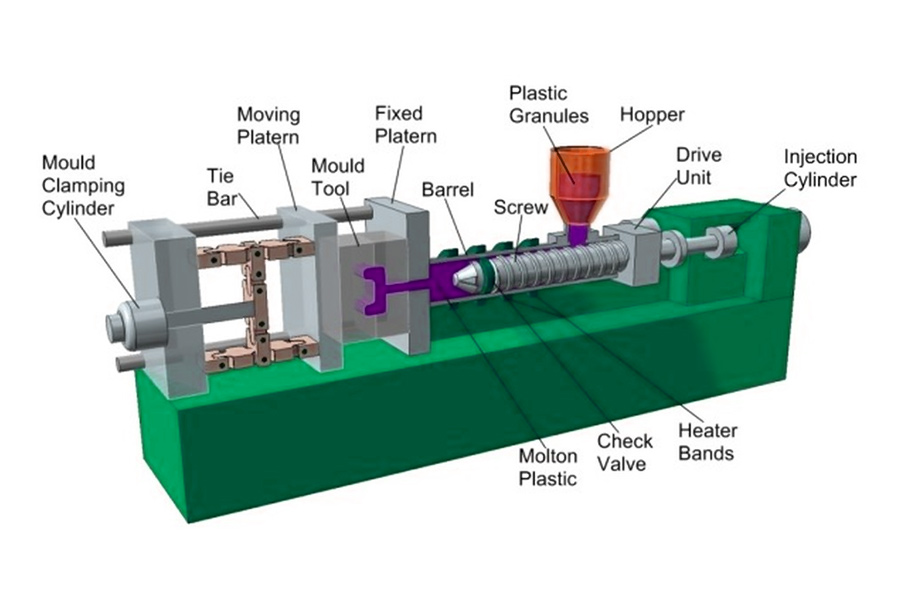

Injection molding is a kind of injection and molding molding method, at a certain temperature, through the screw stir completely molten plastic material, with high pressure into the mold cavity, after cooling and curing, to get the molding product method. This method is suitable for mass production of complex parts.

What Is CNC Machining?

A computer numerical control machine (CNC) is a machining tool that forms stock materials into the desired shape to meet manufacturing instructions and component requirements. CNC machine tools use pre-programmed software to control the movement of complex machinery, including grinders, lathes, milling machines, and other cutting tools used to remove material.

Injection Molding & CNC Machining Advantage And Limiting:

| Feature | CNC Machining | Injection Moulding |

| advantage | With beautiful surface finish and tight tolerances, a variety of materials can be molded and parts design can be modified easily | It can produce a large number of parts quickly and repeatedly, with high production efficiency, long die life and short processing time |

| limiting | The procurement cost of machine tool equipment is more expensive, so the parts price is higher, labor intensive, and the cost increases | A large upfront investment is required, ranging from $50,000 to $100,000, and defects inside the mold can result in finished products with surface defects |

Injection Molding & CNC Machining Application Area:

Injection molding is common in a variety of industries. For example, injection molded plastic parts are found in aerospace watch cases and chassis components, automotive housings and dashboard components, food and beverage, consumer goods, and many other industries.

CNC machining is widely used in automotive, aerospace, medical, electronics and other manufacturing industries. CNC machines can produce high-precision parts and components for a wide range of products, from engine blocks to surgical instruments.

Injection Molding & CNC Machining Main Distinction:

| Function | Injection molding | CNC Machining |

| Available Material | ABS, nylon, PS, ABS, PA, PP, PE, PVC | Metal, aluminum, stainless steel, carbon steel and alloy steel, brass, copper, titanium, magnesium |

| Workpiece Ratio | High | Comparatively High |

| Machining Complexity | medium | medium |

Injection Molding & CNC Machining Key Considerations:

• Production Runs: One key contributing factor is the size of the production run. Though exceptions exist, injection molding is typically only economically feasible when parts are produced in high volumes because the steel and aluminum molds used in the process can be incredibly expensive and time-consuming to manufacture, depending on the complexity of the design.

•Design:Part design introduces another set of considerations that can swing a team’s decision one way or the other. Sharp internal corners, for example, are extremely difficult to achieve with CNC machining unless specialized workarounds are employed, whereas injection molding can generally accommodate these design elements seamlessly.

•Material:Part material must also be taken into consideration, as each process is suited to different types of materials. While many thermoplastics, thermosets, and flexible materials like rubbers and elastomers are ideal for injection molding, CNC machining can lose precision on softer materials. On the other hand, many harder, high-performance plastics can only be machined.

Why Is Longsheng Your Best Choice?

From raw material control to product inspection, we always strive for excellent quality to provide you with impeccable results.

•Superior Technology: With more than 15 years of manufacturing experience, whether it is a simple part or a complex structure, we are able to accurately process, ensuring that every detail is perfectly presented.

•Experience: We have produced more than 80,000 different parts in varying quantities, and almost all customer feedback is good.

•Advanced Equipment: Our manufacturing plants are equipped with advanced production lines that can handle a variety of materials, including metals, plastics and composites.

•Delivery Cycle: same day quotation, the fastest delivery 72 hours.

Comparability:

| Feature | CNC Machining | Injection Molding |

| Speed | Fast | Very Fast |

| Volume | Big | Big |

| Surface Smoothness | Relatively Perfect | Perfect |

| Quality | High | High |

| Price | Relatively Low | Comparatively High |

| Tolerance | 0.001” | 0.005” |

| Wide Range 0f Available Materials | Yes | No |

Conclusion

When selecting a manufacturing process, the overall value and capability of the process should be considered. CNC machining involves the precise removal of layers of material at one time, a process that allows the use of many different materials, can achieve very precise tolerances, machining speed, can process many materials, and fast mold lead time.

Injection molding mass production speed is fast, in the manufacturing process is the lowest price of a single part, the mold life is long, the production of parts fast.

FAQs

Can CNC Machining Process Plastics?

Yes, but plastic because of the relationship between internal stress, easy to crack, this in addition to controlling the speed of the knife, cooling should also pay attention to, not blindly cooling can. Plastic must be processed at a suitable temperature, compared with metal, low hardness, the surface is easy to scratch.

What Are The Significant Advantages Of CNC Machining Compared To Injection Molding?

CNC machining offers design complexity, precision, quality of finish, short lead time, and many other advantages. It is also ideal for producing prototypes with complex geometry and tight tolerances.

Can You Assist With Mold Design And Optimization?

Yes, we have a dedicated design team that can assist with mold creation, optimization and design modification to ensure efficient and high quality production.

I Have A Specific Surface Treatment For Mold Parts, Can You Accommodate It?

Of course! We offer a variety of finishes including matte, glossy, textured and more. Discuss your requirements with our team to ensure the desired results are achieved.

Resource

Everything You Need to Know About CNC Machining for Injection Mold Making