Aerospace manufacturing is known for its high standards and stringent quality requirements. The components used in aircraft and satellites must endure extreme conditions, including high temperatures, atmospheric pressures, and vibrations. The use of aluminum in aerospace manufacturing is widespread due to its lightweight, high strength, and corrosion resistance. However, the manufacturing process of these components requires precision and skill, which can be challenging and expensive.

CNC Machining for Aerospace Manufacturing

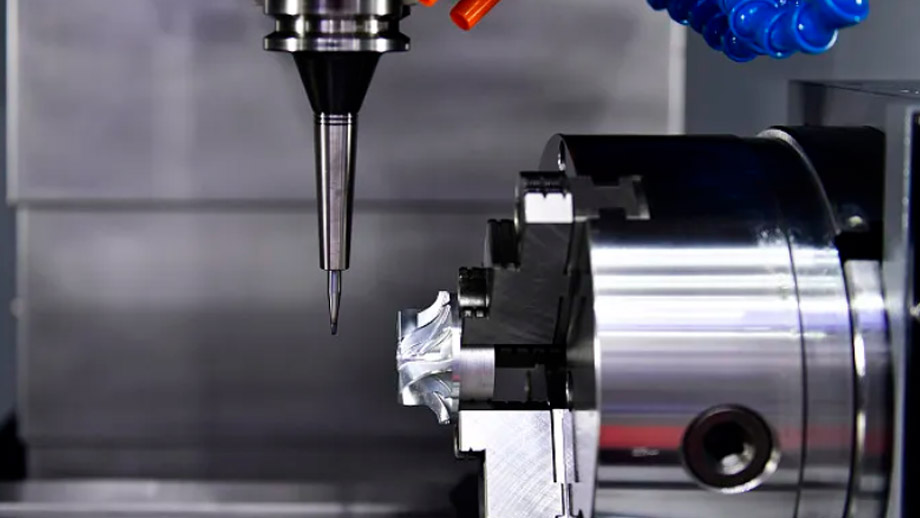

CNC (computer numerical control) machining is a manufacturing process that uses computers to control the movement of machine tools. It has become an essential tool in the production of complex aluminum components for aerospace applications. CNC machining offers several advantages over traditional manufacturing methods:

Precision: CNC machining enables manufacturers to produce components with high levels of precision and accuracy. This is crucial for aerospace applications where even small errors can have serious consequences.

Speed: CNC machines can produce parts at a much faster rate compared to traditional manufacturing methods. This reduces production time and costs, making it more efficient for large-scale manufacturing.

Complexity: CNC machines can create complex shapes and intricate details that would be difficult or impossible to achieve with traditional manufacturing methods. This is particularly advantageous in aerospace manufacturing where lightweighting and reducing drag are critical.

Repeatability: CNC machining offers consistent results, ensuring that each component is produced to the same specifications. This consistency improves quality and reduces variation in production.

Programming: CNC machines are programmable, meaning that manufacturers can create custom programs to machine parts according to specific requirements. This flexibility allows manufacturers to quickly adapt to changing design requirements or production demands.

In summary, CNC machining offers a precise, efficient, and versatile manufacturing solution for the production of aluminum components used in aerospace applications.

Applications in Aerospace Manufacturing

CNC machining is widely used in the production of various aluminum parts for aerospace manufacturing, including:

Engine components: CNC machining is used to manufacture engine components such as pistons, cylinder blocks, and valves. The precision and accuracy of CNC machining ensure that these components function properly under high temperatures and pressures.

Airframe components: CNC machining is used to create airframe components such as wings, fuselages, stabilizers, and tail assemblies. The complex shapes and intricate details required for these components are easily achieved with CNC machining.

Satellite components: CNC machining is used to manufacture satellite components such as antennas, solar arrays, and structural elements. The precision and repeatability of CNC machining ensure that these components meet the stringent requirements of space applications.

Tooling and fixtures: CNC machining is also used to create tooling and fixtures for use in aerospace manufacturing. These tools are critical for ensuring proper component alignment and handling during production.

In conclusion, CNC machining aluminum plays a crucial role in the production of various components used in aerospace manufacturing. If you are looking for CNC machining parts of aerospace, JS Precision is your best choice. We have obtained ISO9001 and AS9100D certificates. Our CNC parts processing equipment and technology are at the leading level in the industry, and we can provide customers with high-quality processing services. We are customer-centric, pay attention to every detail, and guarantee the precision and quality of each part. We provide professional technical consultation and services to ensure customer satisfaction. Welcome to JS Precision for consultation and cooperation.