CNC machining titanium plays a very important role in the high-tech field. Titanium is an important engineering material with excellent properties such as high strength, corrosion resistance, and lightweight, and is widely used in aviation, medicine, automotive, and other fields. However, CNC machining titanium is a challenging task due to its hardness, flammability, and chemical reactivity. Therefore, this article will introduce the basic knowledge of CNC machining titanium, processing difficulties, and how to solve these difficulties.

Characteristics and application of titanium materials

Physical and chemical properties of titanium materials

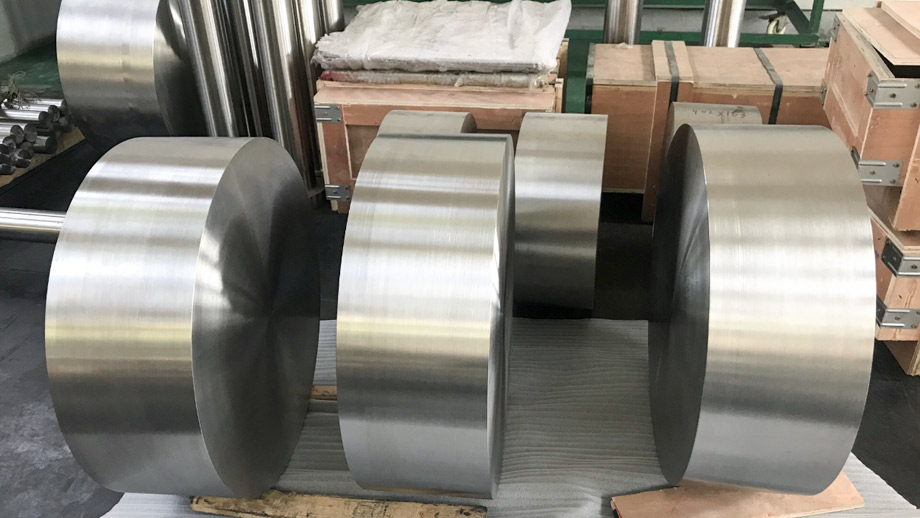

Titanium materials have excellent properties such as low density, high strength, corrosion resistance, and biocompatibility. The density of titanium material is only 4.5g/cm³, which is half that of steel, but its strength is nearly twice that of steel. Titanium material has good corrosion resistance and can be used for a long time in corrosive media such as strong acids and strong alkalis. In addition, titanium materials also have good biocompatibility and can be used to manufacture medical devices such as human implants.

Wide application of titanium materials in aviation, medical, automobile, and other fields

Due to its excellent physical and chemical properties, titanium materials are widely used in aviation, medical, automotive, and other fields. In the field of aviation, titanium materials can be used to manufacture aircraft engine blades, fuselage structural parts, and other important components, which can reduce the weight of aircraft and improve flight efficiency. In the medical field, titanium materials can be used to manufacture human implants, surgical instruments, etc., which can improve the success rate of surgery and reduce surgical complications. In the field of automobiles, titanium materials can be used to manufacture automobile engines, chassis, and other components, which can improve automobile performance and reduce fuel consumption.

The difficulty of CNC machining titanium

Although CNC machining has the advantages of high precision and high efficiency, there are still the following difficulties in machining titanium:

- The hardness of titanium

Titanium has high hardness, which makes it difficult to process. If you choose an inappropriate tool, it will cause excessive cutting force and easily damage the tool and workpiece.

- The flammability of titanium

Titanium is flammable, and it is easy to generate high temperatures and sparks during processing, which can cause fire or explosion accidents.

- The chemical reactivity of titanium

Titanium has strong chemical reactivity, and it is easy to react with cutting fluid and other substances, thus affecting the processing quality.

How to solve the difficulties of CNC machining titanium

In order to solve the difficulties of CNC machining titanium, the following measures can be taken:

- Choose the right tool

Titanium has a high hardness, so it is necessary to choose a suitable tool. Carbide tools or coated tools are usually used to improve cutting efficiency and tool life.

- Control processing parameters

When machining titanium, it is necessary to control the machining parameters, such as cutting speed, feed rate, depth of cut, etc. Reasonable processing parameters can improve processing efficiency while reducing tool wear and workpiece deformation.

- Choose the right coolant

Titanium is flammable, so a suitable coolant needs to be used. Vulcanized liquid or chlorinated liquid is usually used as a cooling liquid to reduce processing temperature and spark splash.

Summary

CNC machining titanium is a challenging task, but by selecting appropriate tools, controlling machining parameters, and selecting appropriate coolants, it is possible to effectively solve machining difficulties and improve machining efficiency and machining quality.

JS Precision is a professional CNC processing manufacturer with rich processing experience. We have obtained ISO9001 and AS9100D certifications and can customize high-quality products for you. If you have high-quality product customization needs, please feel free to contact us.