Introduction

Precision molds are vital components in the manufacturing industry. They are used to create products with high accuracy and consistency, making them essential in various industries such as automotive, aerospace, electronics, and more. However, the production of precision molds can be challenging, requiring expertise, experience, and attention to detail. In this article, we will discuss some optimization methods for precision mold production to improve efficiency, and quality, and reduce costs.

Design Optimization

The first step in precision mold production is designing the mold. Design optimization involves creating a mold that produces parts that meet the desired specifications while minimizing material waste and reducing production time. To achieve this, designers must consider factors such as the geometry of the part, material properties, and the mold’s cooling system.

One way to optimize the design is to use computer-aided design (CAD) software. CAD software allows designers to create 3D models of the mold and simulate its performance before production. This allows them to identify potential issues and make necessary changes before the mold is manufactured, reducing the risk of errors and saving time and money.

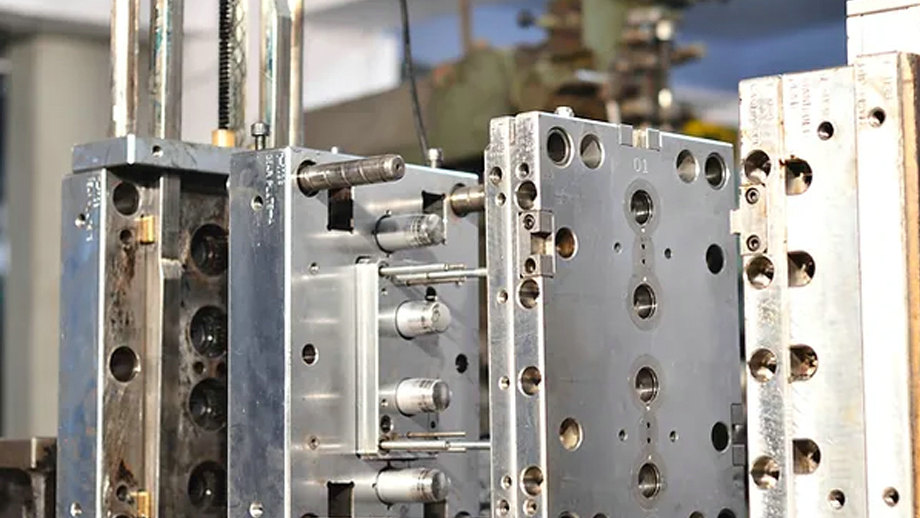

Material Selection and Preparation

The material used to create the mold is crucial to its performance and longevity. The material must be strong, durable, and resistant to wear and corrosion. Aluminum and steel are common materials used in precision mold production. Choosing the right material depends on the specific requirements of the mold and the part it produces.

Once the material is selected, it must be prepared for the manufacturing process. Proper preparation involves cutting the material to the desired size and shape and removing any defects or impurities. This ensures that the mold is of high quality and produces parts that meet the desired specifications.

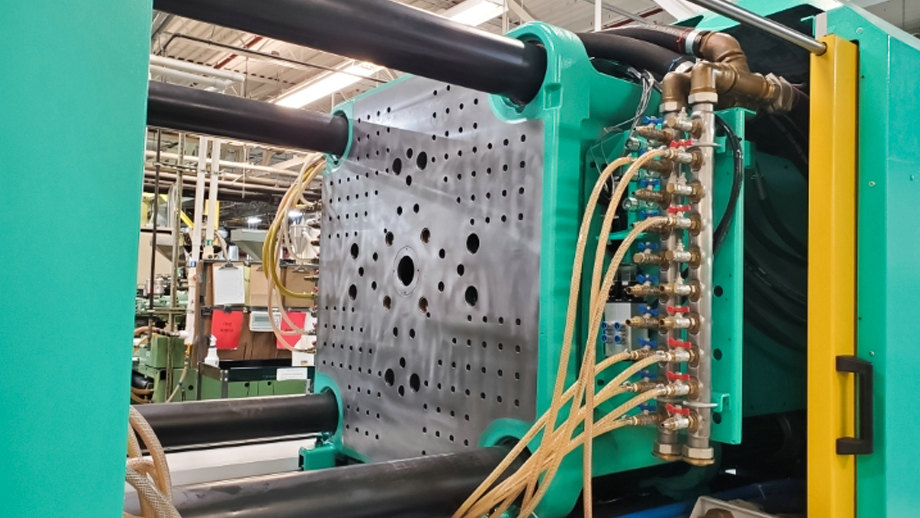

Manufacturing Optimization

Manufacturing optimization involves the actual production of the mold. One way to optimize the manufacturing process is to use computer numerical control (CNC) machines. CNC machines are computer-controlled machines that can produce high-precision parts with minimal human intervention. This reduces the risk of errors and increases production efficiency.

Another way to optimize the manufacturing process is to use additive manufacturing. Additive manufacturing, also known as 3D printing, involves creating a mold layer by layer using a digital model. This method is ideal for creating complex molds and reduces the time and cost of traditional manufacturing methods.

Quality Control Optimization

Quality control is crucial in precision mold production. It ensures that the mold produces parts that meet the desired specifications and reduces the risk of errors and defects. One way to optimize the quality control process is to use coordinate measuring machines (CMMs). CMMs are computer-controlled machines that measure the dimensions and geometry of the mold with high accuracy. This allows manufacturers to identify any discrepancies and make necessary adjustments before production.

Another way to optimize quality control is to use statistical process control (SPC). SPC involves monitoring the production process and identifying any variations or defects. This allows manufacturers to make necessary adjustments and improve the production process.

Conclusion

Precision mold production requires expertise, experience, and attention to detail. By optimizing the design, material selection, and preparation, manufacturing, and quality control processes, manufacturers can improve efficiency, and quality, and reduce costs. With the advancement of technology, there are more and more methods for optimizing precision mold production. It is important for manufacturers to stay up-to-date with the latest trends and technologies to remain competitive in the industry.

JS Precision is a professional injection mold manufacturer, which can customize high-quality molds and injection molding services on demand. If you have related needs, please contact us.