I. Introduction

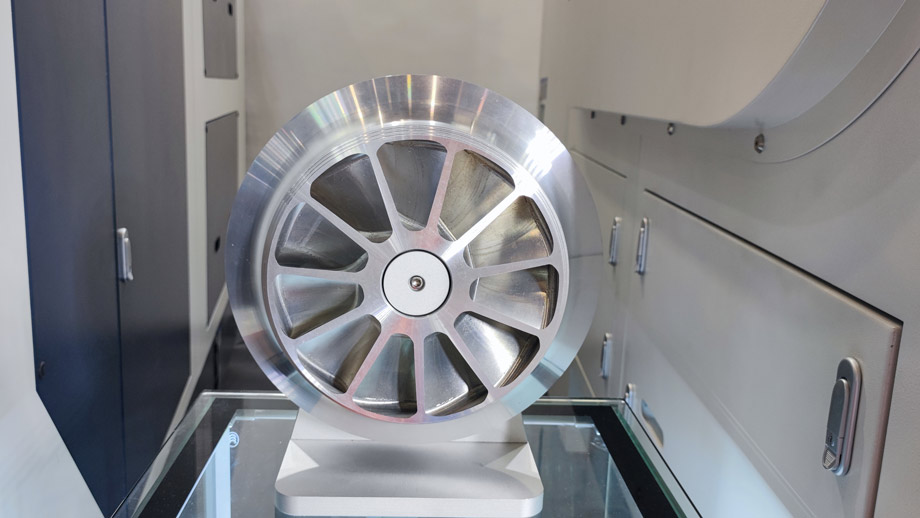

CNC machining is an essential process in modern manufacturing, providing high precision and accuracy in the production of complex parts and components. The use of aluminum in CNC machining has become increasingly popular due to its lightweight, durable, and versatile properties. In this article, we will explore the advantages of aluminum CNC machining for precise parts and its benefits across various industries.

II. Advantages of Aluminum CNC Machining for Precise Parts

a. High precision and accuracy

One of the main advantages of aluminum CNC machining is its ability to achieve high precision and accuracy in the production of complex parts. CNC machines use computer-controlled software to execute precise cuts, drills, and milling operations, resulting in parts with tight tolerances and minimal errors.

b. Consistency and repeatability

Another benefit of aluminum CNC machining is its consistency and repeatability in producing identical parts. CNC machines can produce large quantities of parts with consistent quality and accuracy, eliminating the risk of human error and reducing production time.

c. Faster production times

Aluminum CNC machining can also result in faster production times due to the automation of the manufacturing process. CNC machines can work continuously and tirelessly, reducing the time required to produce parts compared to traditional manufacturing methods.

d. Cost-effectiveness

Aluminum CNC machining can be cost-effective in the long run due to its high precision and accuracy, which reduces the need for additional machining and finishing processes. CNC machines also require minimal supervision, reducing labor costs and increasing productivity.

e. Versatility and flexibility

Aluminum CNC machining is a versatile and flexible process that can produce parts of various shapes, sizes, and complexities. CNC machines can also work with a wide range of materials, including metals, plastics, and composites, making it suitable for various industries.

III. Benefits of Aluminum CNC Machining for Various Industries

a. Aerospace and aviation

Aluminum CNC machining is widely used in the aerospace and aviation industry due to its lightweight, high-strength, and corrosion-resistant properties. CNC machines can produce complex parts for aircraft, satellites, and spacecraft with high precision and accuracy.

b. Automotive

The automotive industry also benefits from aluminum CNC machining, as it can produce parts for engines, transmissions, and chassis with high precision and accuracy. CNC machines can also produce custom parts for racing and high-performance vehicles.

c. Medical and healthcare

Aluminum CNC machining is crucial in the medical and healthcare industry, as it can produce complex parts for medical devices, implants, and prosthetics. CNC machines can also work with biocompatible materials, ensuring the safety and efficacy of medical products.

d. Electronics and technology

The electronics and technology industry also relies on aluminum CNC machining for the production of complex parts for electronic devices, computer components, and telecommunications equipment. CNC machines can produce parts with high precision and accuracy, ensuring the functionality and reliability of electronic products.

e. Consumer goods

Aluminum CNC machining is also used in the production of consumer goods, such as watches, jewelry, and accessories. CNC machines can produce intricate and detailed parts with high precision and accuracy, enhancing the aesthetic appeal and functionality of consumer products.

IV. Factors to Consider When Choosing Aluminum CNC Machining Services

a. Experience and expertise

When choosing an aluminum CNC machining service provider, it is essential to consider their experience and expertise in the field. A reputable service provider should have a team of skilled and knowledgeable professionals who can deliver high-quality and precise parts.

b. Quality assurance and certifications

Quality assurance and certifications are crucial in ensuring the quality and reliability of aluminum CNC machining services. A reputable service provider should have certifications such as ISO 9001 and AS9100, indicating their commitment to quality and customer satisfaction.

c. Equipment and technology

The equipment and technology used by the service provider can also affect the quality and precision of the parts produced. A reputable service provider should have state-of-the-art CNC machines and software, ensuring the accuracy and consistency of the manufacturing process.

d. Materials and finishes

The materials and finishes used by the service provider can also affect the quality and durability of the parts produced. A reputable service provider should have a wide range of materials and finishes to choose from, ensuring the suitability of the parts for their intended application.

e. Customer service and support

Customer service and support are crucial in ensuring a smooth and hassle-free manufacturing process. A reputable service provider should have excellent customer service and support, providing timely and effective solutions to any issues or concerns.

V. Conclusion

Aluminum CNC machining offers numerous benefits and advantages in producing precision parts for a wide variety of industries. Its high precision and accuracy, consistency and repeatability, faster production times, cost-effectiveness, versatility, and flexibility make it a popular choice for modern manufacturing. JS Precision is a professional aluminum CNC processing manufacturer. We have rich experience, advanced production equipment, testing equipment, and a professional engineering team, and can provide you with high-quality aluminum CNC customization services. Contact us now to make your dream a reality.