Are you struggling with frequent injection molding machine failures? Are you looking for ways to improve your machine’s performance and reduce downtime? If so, you’re in the right place. In this article, we’ll introduce you to the basics of injection molding machine management and provide you with preventive measures to reduce machine failures.

What is Injection Molding Machine Management?

Injection molding machine management refers to the process of overseeing and optimizing the performance of injection molding machines. Effective management involves ensuring that the machine is properly maintained, operated, and monitored to achieve optimal performance.

Why is Injection Molding Machine Management Important?

Effective injection molding machine management is critical to maintaining the quality, productivity, and profitability of your manufacturing operations. Poorly managed machines can result in frequent breakdowns, low-quality parts, and costly downtime. On the other hand, well-managed machines can help you produce high-quality parts consistently, reduce scrap rates, and minimize downtime.

Preventive Measures to Reduce Injection Molding Machine Failures

- Regular Maintenance

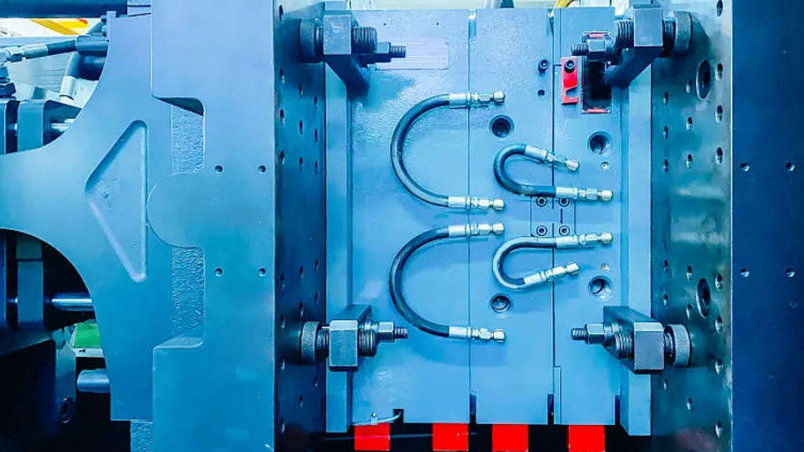

Regular maintenance is critical to the proper functioning of injection molding machines. Routine maintenance tasks include cleaning, lubrication, and inspection of critical components such as the injection unit, clamping unit, and hydraulic system.

- Operator Training

Proper operator training is essential to the safe and effective operation of injection molding machines. Operators should be trained on how to operate the machine, perform routine maintenance tasks, and understand the proper use of safety equipment.

- Monitoring and Control

Injection molding machines should be equipped with monitoring and control systems that enable operators to monitor key process parameters such as temperature, pressure, and cycle time. This allows operators to identify potential problems before they result in machine failures.

- Quality Control

Quality control procedures should be implemented to ensure that the parts produced by the injection molding machine meet the required specifications. This includes inspecting parts for defects, measuring critical dimensions, and verifying material properties.

- Troubleshooting

When machine failures occur, troubleshooting procedures should be implemented to quickly identify and resolve the problem. Troubleshooting procedures should include a systematic approach to identifying the root cause of the problem and implementing corrective actions.

Conclusion

Effective injection molding machine management is critical to the success of your manufacturing operations. By following the preventive measures outlined in this article, you can reduce machine failures, improve part quality, and increase profitability. If you’re looking for more information on injection molding machine management, contact JS Precision today. Our team of experts can help you optimize your injection molding operations and achieve your business goals.