If you are in the manufacturing industry, you know that injection molding is one of the most commonly used processes for producing plastic parts. The quality of the final product depends on the precision of the mold, and one of the critical factors that influence this is the temperature control. In this article, we will dive into the injection mold temperature control method and analyze the various factors that can affect the process.

What is Injection Mold Temperature Control?

Injection mold temperature control refers to the process of regulating the temperature of the mold during the injection molding process. The primary purpose of this is to ensure that the plastic material is injected into the mold cavity in its optimal state, reducing the risk of defects and ensuring a high-quality final product.

Methods of Injection Mold Temperature Control

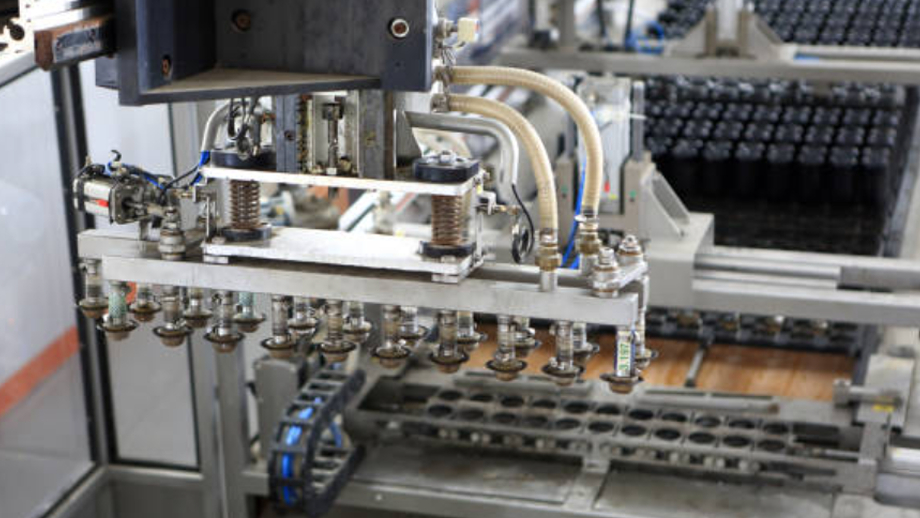

There are two methods of injection mold temperature control: hot runner and cold runner systems.

Hot Runner System

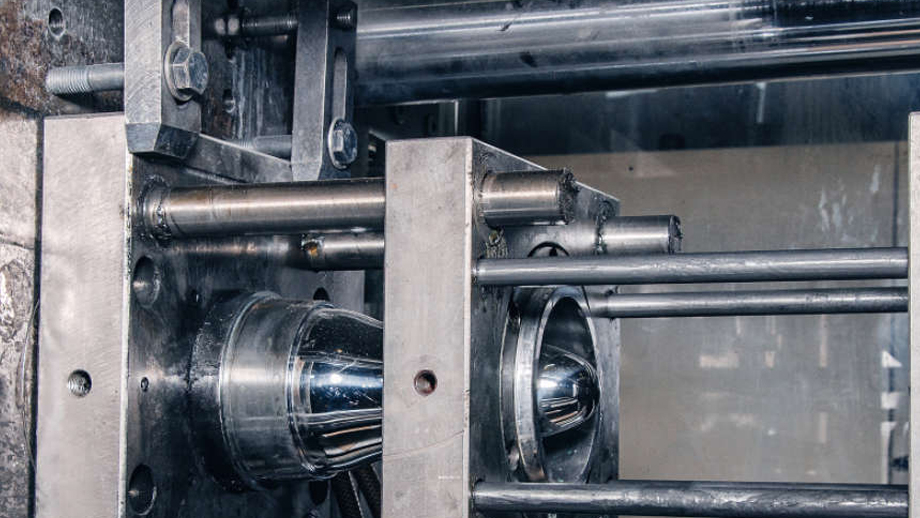

In a hot runner system, the mold is heated from the inside with a network of channels that allow the molten plastic to flow through. This ensures that the plastic material is always at the ideal temperature, reducing the risk of defects and improving the quality of the final product. Hot runner systems are commonly used for high-volume production runs and are ideal for complex parts that require precise molding.

Cold Runner System

In a cold runner system, the mold is not heated, and the plastic material is injected through a sprue and runner system. The plastic material cools as it flows through the mold, and the temperature is controlled through the use of cooling channels. Cold runner systems are commonly used for low-volume production runs and are ideal for simple parts that do not require precise molding.

Factors that Affect Injection Mold Temperature Control

Several factors can affect the temperature control of an injection mold. These factors include:

Mold Temperature

The temperature of the mold is critical to the injection molding process. If the mold is too hot, the plastic material will not solidify correctly, resulting in defects such as warping and shrinkage. If the mold is too cold, the plastic material will not flow freely, resulting in incomplete filling and other defects.

Plastic Material

Different types of plastic materials have different melting points and require different temperatures for optimal processing. It is essential to understand the properties of the plastic material being used and adjust the mold temperature accordingly.

Injection Pressure

The injection pressure of the plastic material can affect the temperature control of the mold. If the injection pressure is too high, the plastic material may become too hot, resulting in defects such as warping and shrinkage. If the injection pressure is too low, the plastic material may not flow freely, resulting in incomplete filling and other defects.

Cooling Time

The cooling time of the mold can affect the temperature control of the mold. If the cooling time is too short, the plastic material may not solidify correctly, resulting in defects such as warping and shrinkage. If the cooling time is too long, the cycle time may be extended, reducing productivity and increasing costs.

Conclusion

Injection mold temperature control is a critical factor in the injection molding process. Proper temperature control can help ensure a high-quality final product, reduce the risk of defects, and increase productivity. Understanding the various factors that influence injection mold temperature control can help manufacturers optimize their injection molding process and produce high-quality plastic parts. At JS Precision, we are committed to providing our customers with the highest-quality injection molding services. Contact us today to learn more about our services and how we can help you with your injection molding needs.