Are you wondering which machining process is better for your manufacturing needs? 5-axis machining and 3-axis machining are two popular options, each with its own advantages and disadvantages. In this article, we will explore the differences between these two processes and help you determine which one is best suited for your project.

What is 5-Axis Machining?

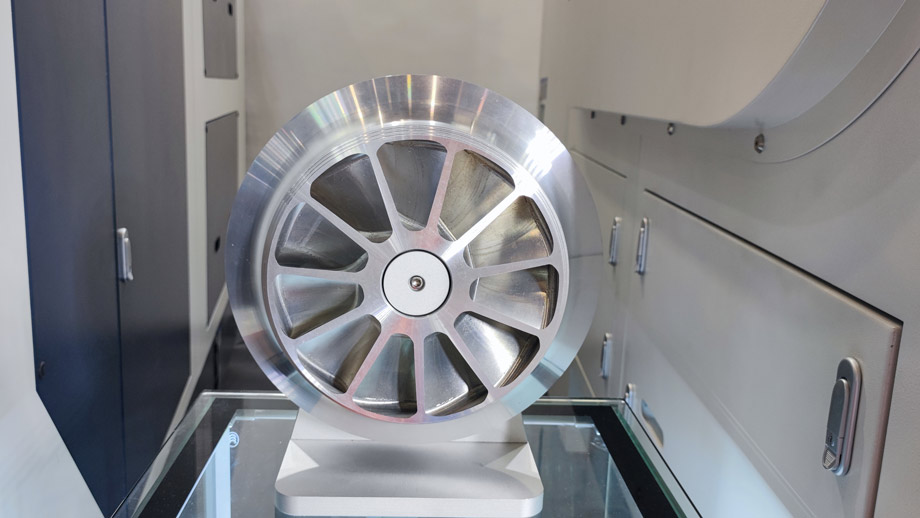

5-axis machining is a process that involves cutting material along five axes simultaneously. This process is accomplished with a 5-axis CNC machine, which has three linear axes (X, Y, and Z) and two rotational axes (A and B). The cutting tool can move along all five axes, allowing for greater flexibility and precision.

Advantages of 5-Axis Machining

One of the main advantages of 5-axis machining is that it can produce complex shapes and features that would be difficult or impossible to create with 3-axis machining. The ability to move the cutting tool along multiple axes also allows for faster and more efficient machining, as well as reduced tool wear. Additionally, 5-axis machining can often reduce the number of setups required, which can save time and money.

Disadvantages of 5-Axis Machining

The main disadvantage of 5-axis machining is the cost. 5-axis CNC machines are more expensive than 3-axis machines, and they require more skilled operators to program and operate. Additionally, the increased complexity of the process can lead to longer setup times and increased risk for errors.

What is 3-Axis Machining?

3-axis machining is a simpler process that involves cutting material along three linear axes (X, Y, and Z). This process is accomplished with a 3-axis CNC machine, which can move the cutting tool along these three axes to create the desired shape or feature.

Advantages of 3-Axis Machining

One of the main advantages of 3-axis machining is the lower cost. 3-axis CNC machines are less expensive than 5-axis machines, and they require less skilled operators to program and operate. Additionally, 3-axis machining is a simpler process that can be used for a wide range of parts and materials.

Disadvantages of 3-Axis Machining

The main disadvantage of 3-axis machining is the limited flexibility. Because the cutting tool can only move along three axes, it can be difficult or impossible to create complex shapes or features. Additionally, 3-axis machining can be slower and less efficient than 5-axis machining, especially for parts with intricate geometries.

Which is Better for Your Project?

Choosing between 5-axis and 3-axis machining depends on the specific needs of your project. If you require complex shapes or features, or if you need to produce parts with tight tolerances, 5-axis machining may be the better option. However, if you are working with simpler parts or materials, or if cost is a concern, 3-axis machining may be the better choice.

Why Choose JS Precision for Your Machining Needs?

At JS Precision, we specialize in both 5-axis and 3-axis machining, as well as a range of other manufacturing processes. Our team of skilled operators and engineers can help you determine the best machining process for your project, and provide high-quality parts and components that meet your exact specifications. Contact us today to learn more about our capabilities and how we can help you with your next project.