If you are in the sheet metal fabrication industry, you know that quality is key. From design to final production, every step in the process requires a commitment to excellence. This article will explore the various quality control and inspection methods used in sheet metal fabrication and highlight the importance of choosing a partner who values quality as much as you do.

Introduction

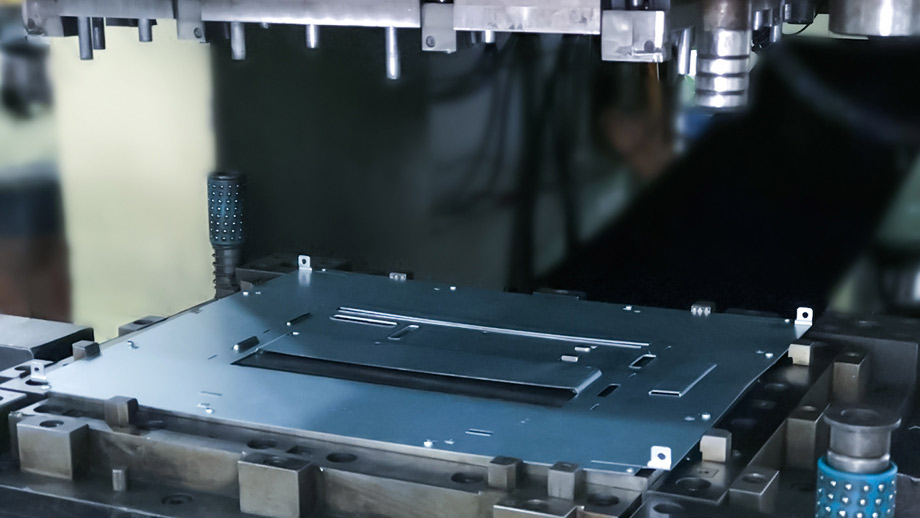

Sheet metal fabrication involves the cutting, bending, and shaping of metal sheets to create a finished product. This process requires precision, skill, and attention to detail. Quality control and inspection are vital to ensuring that the final product meets the required specifications and standards.

Quality Control Methods

Quality control begins with the design process. The design should be reviewed and approved to ensure that it meets the necessary requirements. Once the design is approved, the fabrication process can begin.

During the fabrication process, several quality control methods are used to ensure that the finished product is of the highest quality. These methods include:

- Visual Inspection – This involves a detailed inspection of the product to ensure that it meets the required specifications. This can include checking for defects, scratches, and other imperfections.

- Dimensional Inspection – This involves measuring the product to ensure that it meets the required dimensions. This can include checking the thickness, length, and width of the product.

- Material Inspection – This involves inspecting the raw materials used in the fabrication process to ensure that they meet the required specifications. This can include checking the hardness, strength, and durability of the materials.

- Weld Inspection – This involves inspecting the welds used in the fabrication process to ensure that they are strong and durable. This can include checking for cracks, defects, and other imperfections.

Inspection Methods

Once the fabrication process is complete, the finished product undergoes a final inspection to ensure that it meets the required specifications and standards. This final inspection can include:

- Non-Destructive Testing – This involves testing the product without damaging it. This can include ultrasonic testing, X-ray testing, and magnetic particle testing.

- Destructive Testing – This involves testing the product by destroying it. This can include tensile testing, bend testing, and impact testing.

- Performance Testing – This involves testing the product to ensure that it performs as expected. This can include testing the product under various conditions to ensure that it meets the required standards.

Conclusion

Quality control and inspection are critical components of the sheet metal fabrication process. These methods ensure that the finished product meets the required specifications and standards. When choosing a partner for your sheet metal fabrication needs, it is essential to choose one who values quality as much as you do. At JS Precision, we are committed to providing our customers with the highest quality products and services. Contact us today to learn more.