Sheet metal stamping is a process used to transform flat sheets of metal into different shapes using a stamping press. This process is widely used in industries such as automotive, aerospace, and construction. At JS Precision, we specialize in sheet metal stamping and provide our customers with high-quality products that meet their unique requirements. In this article, we will provide a comprehensive guide on what sheet metal stamping is, its benefits, and the different types of sheet metal stamping processes.

What is Sheet Metal Stamping?

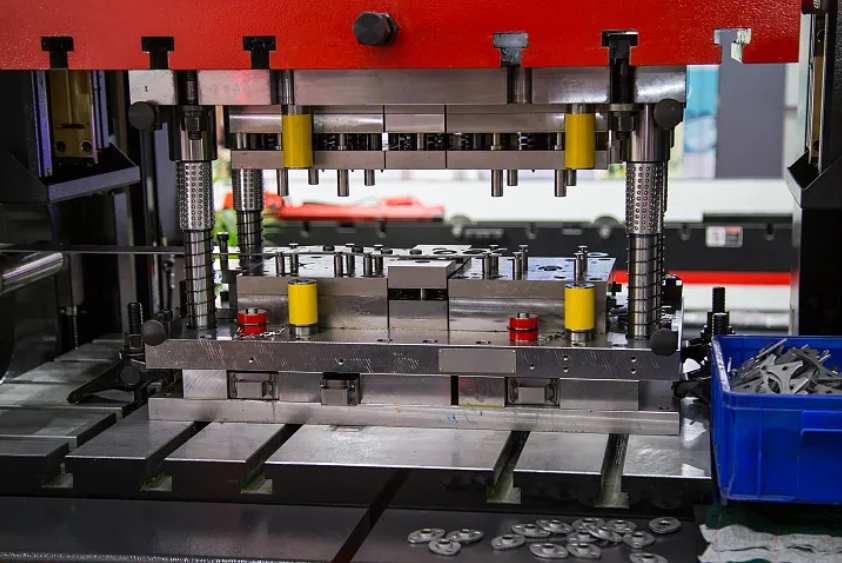

Sheet metal stamping is a manufacturing process that involves transforming flat sheets of metal into different shapes and sizes using a stamping press. The process is achieved by placing the sheet metal into a die and applying pressure to it using a stamping press. The pressure applied to the metal sheet causes it to take on the shape of the die. The process is repeated until the desired shape is achieved.

Benefits of Sheet Metal Stamping

Sheet metal stamping has several benefits, including:

1. High accuracy: Sheet metal stamping is a highly accurate process that produces parts with very tight tolerances. This makes it an ideal process for producing parts that require high precision.

2. Cost-effective: Sheet metal stamping is a cost-effective process, especially when producing large quantities of parts. The process is also highly automated, which reduces labor costs.

3. Versatile: Sheet metal stamping can be used to produce a wide range of parts, including complex shapes. This makes it an ideal process for producing parts with unique designs.

4. High production rate: Sheet metal stamping is a fast process that can produce large quantities of parts in a short amount of time. This makes it an ideal process for mass production.

Types of Sheet Metal Stamping Processes

There are several types of sheet metal stamping processes, including:

1. Blanking: This process involves cutting a flat sheet of metal into a specific shape using a die. The resulting piece is called a blank.

2. Bending: This process involves bending a metal sheet into a specific shape using a die. The process is repeated until the desired shape is achieved.

3. Drawing: This process involves pulling a metal sheet through a die to create a specific shape. The process is repeated until the desired shape is achieved.

4. Forming: This process involves deforming a metal sheet into a specific shape using a die. The process is repeated until the desired shape is achieved.

5. Piercing: This process involves punching holes into a metal sheet using a die.

Conclusion

Sheet metal stamping is a highly versatile and cost-effective process that is widely used in various industries. At JS Precision, we specialize in sheet metal stamping and provide our customers with high-quality products that meet their unique requirements. If you require sheet metal stamping services, please contact us today, and we will be happy to assist you.