I. The Necessity of Prototype Machining

When it comes to industrial manufacturing, creating a prototype is an essential step in the process. A prototype allows engineers to test and refine their designs before mass production begins. Without creating a prototype, a manufacturer runs the risk of producing a faulty product that can lead to significant financial losses and damage to the company’s reputation. The importance of creating a prototype cannot be overstated, and it is crucial to get it right the first time.

II. Why You Should Use CNC Machining for Prototypes

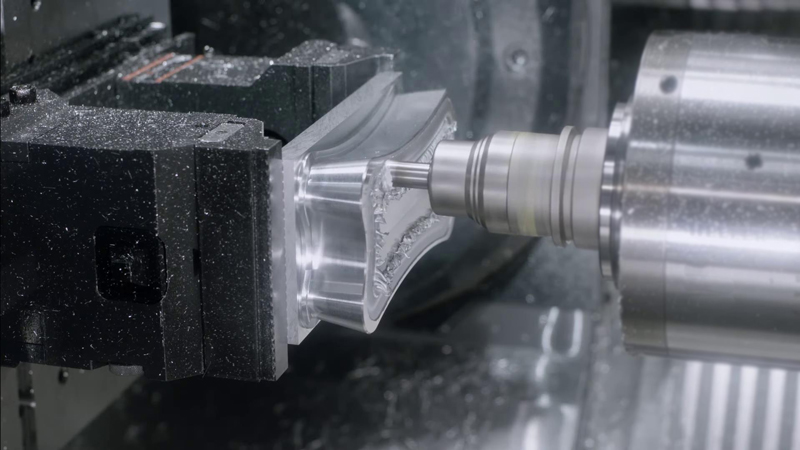

When it comes to creating a prototype, there are several methods to choose from. One of the most popular methods is CNC machining. CNC machining is a computer-controlled process that uses precision tools to create parts with high accuracy and repeatability. CNC machining is a highly efficient and cost-effective way to create prototypes that meet the specific design requirements of the project.

JS Precision is a professional CNC parts processing manufacturer with rich production experience and advanced production equipment. We specialize in providing high-quality CNC machining services for industrial manufacturing. Our CNC machines use the latest technology to produce parts with high precision and accuracy, making them the ideal choice for creating prototypes.

III. Tips for Designing CAD for Prototype CNC Machining

Designing CAD for prototype CNC machining requires careful consideration of several factors. Here are some tips for designing CAD for prototype CNC machining:

1. Keep it simple: Simpler designs are easier to machine and can reduce the cost of production.

2. Use the right materials: Selecting the right materials for your prototype is essential. Consider the properties of the material and how it will affect the final product.

3. Consider tolerances: Tolerances are the allowable deviation from the specified dimensions. It is essential to consider tolerances when designing CAD for CNC machining as they can affect the final product’s accuracy.

4. Test the design: Before sending the design to be machined, it is crucial to test it to ensure it meets the project’s requirements.

At JS Precision, we have a team of experienced engineers who can help you design CAD for your prototype CNC machining project. Our goal is to provide you with a high-quality prototype that meets your specific requirements.

In conclusion, creating a prototype is an essential step in industrial manufacturing, and CNC machining is an excellent choice for creating these prototypes. With JS Precision’s advanced production equipment and rich production experience, we can provide you with high-quality CNC machining services to meet your specific needs. By following these tips for designing CAD for prototype CNC machining, you can ensure that your prototype is accurate, efficient and meets the project’s requirements. Contact us today for a product quotation consultation.