Our Services

We can provide you with high-quality rapid customization services from prototype to mass production, including CNC Machining parts, Sheet Metal parts, Extrusion parts, Die Casting parts, Stamping parts, Spring Machining parts, Injection Molding parts, 3D Printing parts, and Surface Finishing.

CNC Machining

Milling, turning, and post-processing.Tolerances down to ±0.002-0.005mm. Lead times from 3 business days.

3D Printing

FDM, SLA, SLS, MJF.Tolerances down to ±(0.010 mm). Lead times from 1 business day.

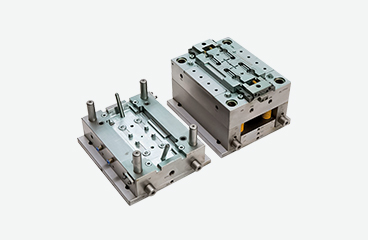

Injection Molding

Prototypes and production tooling.Wide range of part complexities and sizes.

Sheet Metal Fabrication

Laser cutting, bending, post-processing.Tolerances down to ±(0.010 mm). Lead times from 5 business days.

Metal Stamping

Support stamping parts of various shapes and sizes to be customized.Tolerances down to ±0.01 mm. Lead times from 3 business days.

Spring Machining

compression springs, extension springs, torsional springs, customized springs.from rapid prototyping and end-use production.

About JS

JS Precision Technology is a CNC machining, sheet metal, extrusion, die casting, stamping, spring machining, injection molding, 3D printing, and surface finishing service factory & manufacture from China.

Our state-of-the-art CNC machining, sheet metal, extrusion, die casting, stamping, spring machining, injection molding, 3D printing, and surface finishing equipment allows us to deliver products with tight tolerances, precise dimensions, and consistent quality. We are dedicated to helping our customers succeed and are committed to providing the best quality parts and services at competitive prices.

Contact us now to realize your high-quality products from prototype to mass production as fast as 3 days

Why Choose Us

What Sets Us Apart

Exceptional customer service

We prioritize our clients and strive to exceed their expectations in every aspect of our service, from communication to project delivery.

Competitive pricing

We offer competitive pricing for all of our parts machining services without compromising on quality

High-quality products

We use only the best machining materials and employ strict quality control measures to ensure that our products meet the highest standards.

Highly skilled team

Our team of engineers and technicians are highly skilled and experienced in CNC machining, with a proven track record of delivering high-quality products

Customized solutions

We work closely with our clients to understand their unique needs and provide metal parts customized solutions that meet their specific requirements.

Capacity and flexibility

Our state-of-the-art machining equipment and flexible metal parts manufacturing processes allow us to handle projects of all sizes and complexity, from small prototypes to large production runs.

Testimonial

Let's build something great, together

Contact us for rapid and efficient machining services. Leave us a message now for swift and effective completion of your project

Blog post

Explore our latest machining news! From innovative technologies to industry trends, we bring you exciting stories in just 30 words. Learn how we're leading the way in the machining industry.

-

19 Jul 2024Stainless Steel vs Aluminum: What are the Differences?

-

11 Jul 2024An Ultimate Guide To Sheet Metal Hemming

-

11 Jul 2024Welding Imperfections: Types, Causes & Preventive Takeups

-

05 Jul 2024Stainless Steel Machining: Grades, Applications, & Challenges

-

05 Jul 2024Sheet Metal Surface Finishes Choices For Your Mission

-

28 Jun 2024What are Machining Defects? And How To Fix Machining Defects?

-

21 May 2024What Is The Difference Between Die Casting And Machining?

-

18 May 2024What Is 3 Axis 4 Axis 5 Axis and 7 Axis CNC Machining?

-

11 Mar 20243D Printing vs Compression Molding: Which One To Choose?

-

23 Feb 20243D Printing in Consumer Goods Manufacturing

CNC Machining Services Custom Parts Online Quote Manufacturer

Start Your Project With A Free Quote